Zirconium boride based ceramic and preparation method thereof

A zirconium boride-based, zirconium boride technology, applied in the field of zirconium boride-based ceramics and its preparation, can solve problems such as difficult sintering and compaction, and achieve good compactness, high temperature resistance, good compactness and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

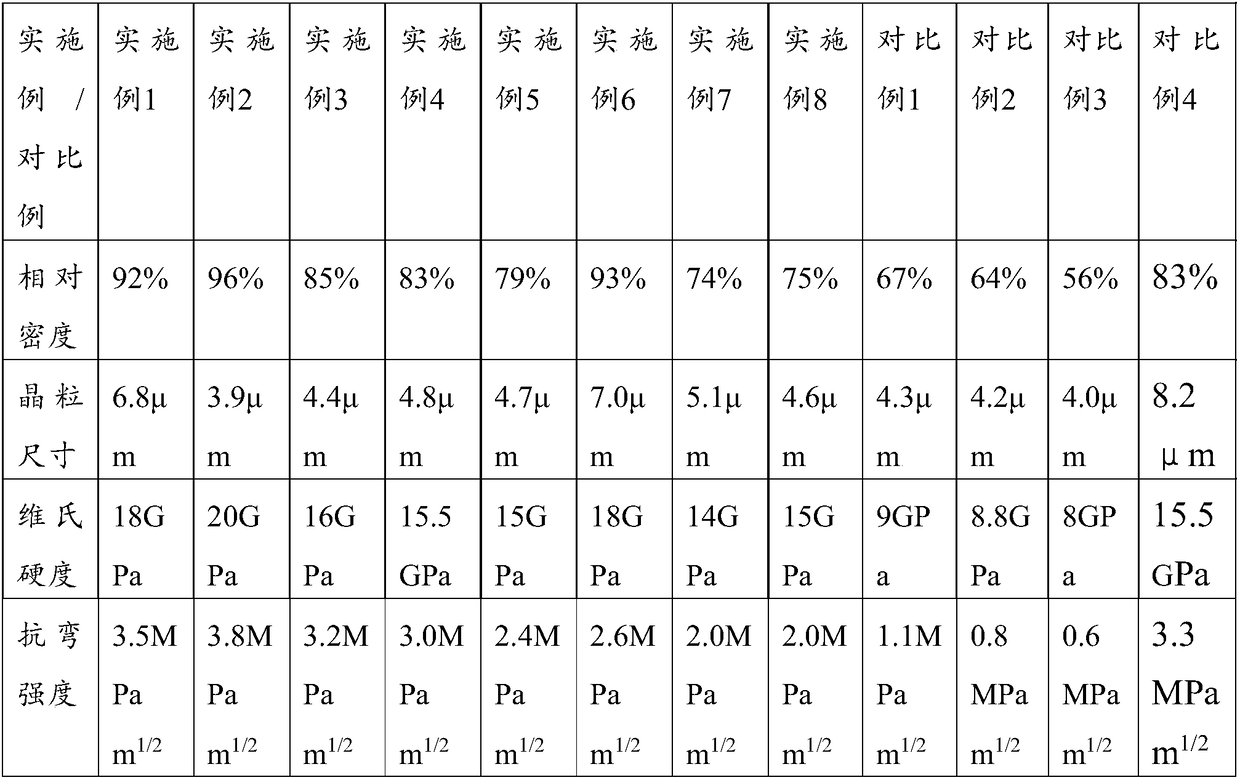

Examples

Embodiment 1

[0031] Step 1: add diammonium citrate, urea and ammoniacal liquor in deionized water, adjust the pH value to be 9.5, and carry out magnetic stirring under the rotating speed of 500 rpm, add zirconium boride (ZrB 2 ) powder, continue to stir for 2 hours, then add silicon nitride (Si 3 N 4 ) balls were ball milled at a speed of 300r / min. After 24 hours, add an appropriate amount of polyvinyl butyral (PVB) binder, and then ball mill for 24 hours, and pass the ball milled slurry through spray granulation equipment to prepare ZrB with a particle size of about 50 μm 2 Pellet balls.

[0032] Step 2: Mix ZrB with a volume ratio of 4:1 2 Pellet balls and zirconia (ZrO 2 ) powder was dissolved in acetone without ball milling medium, and ball milled on a roller ball mill for 8 hours to make ZrB 2 The surface of the granulation ball is coated with a layer of ZrO 2 powder, and after drying by rotary evaporation, a uniformly mixed ZrB 2 -ZrO 2 Mix powder. ZrB 2 -ZrO 2 Put the mix...

Embodiment 2

[0035] Step 1: Add diammonium citrate, urea and ammonia water to deionized water, adjust the pH value to 9.5, and perform magnetic stirring at a speed of 500 rpm, and add ZrB after 3 hours 2 powder, continue to stir for 2 hours, then add silicon nitride (Si 3 N 4 ) balls were ball milled at a speed of 300r / min. After 24 hours, add an appropriate amount of polyvinyl butyral (PVB) binder, and then ball mill for 24 hours, and pass the ball milled slurry through spray granulation equipment to prepare ZrB with a particle size of about 50 μm 2 Pellet balls.

[0036] Step 2: Mix ZrB with a volume ratio of 85:15 2 Pellet balls and zirconia (ZrO 2 ) powder was dissolved in acetone with a pH of 10.5, without ball milling medium, and ball milled on a roller ball mill for 8 hours to make ZrB 2 The surface of the granulation ball is coated with a layer of ZrO 2 powder, and after drying by rotary evaporation, a uniformly mixed ZrB 2 -ZrO 2 Mix powder. ZrB 2 -ZrO 2 Put the mixed p...

Embodiment 3

[0039] Step 1: add diammonium citrate, urea and ammoniacal liquor in deionized water, adjust the pH value to be 9.5, and carry out magnetic stirring under the rotating speed of 500 rpm, add zirconium boride (ZrB 2 ) powder, continue to stir for 2 hours, then add silicon nitride (Si 3 N 4 ) balls were ball milled at a speed of 300r / min. After 24 hours, add an appropriate amount of polyvinyl butyral (PVB) binder, and then ball mill for 24 hours, and pass the ball milled slurry through spray granulation equipment to prepare ZrB with a particle size of about 50 μm 2 Pellet balls.

[0040] Step 2: Mix ZrB with a volume ratio of 85:15 2 Pellet balls and zirconia (ZrO 2) powder was dissolved in ethanol with a pH of 10.5, without ball milling medium, and ball milled on a roller mill for 8 hours to make ZrB 2 The surface of the granulation ball is coated with a layer of ZrO 2 powder, and after drying by rotary evaporation, a uniformly mixed ZrB 2 -ZrO 2 Mix powder. ZrB 2 -ZrO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com