Preparation method of ruthenium/boron carbide multilayer film mirror for monochromator

A boron carbide and mirror technology, applied in coating, sputtering, metal material coating processes, etc., can solve the problems of reducing the optical properties of the film, hindering the application of the film, cracking the film, etc., to avoid the film The effect of shedding failure, avoiding the deformation of the substrate surface, and reducing the stress of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

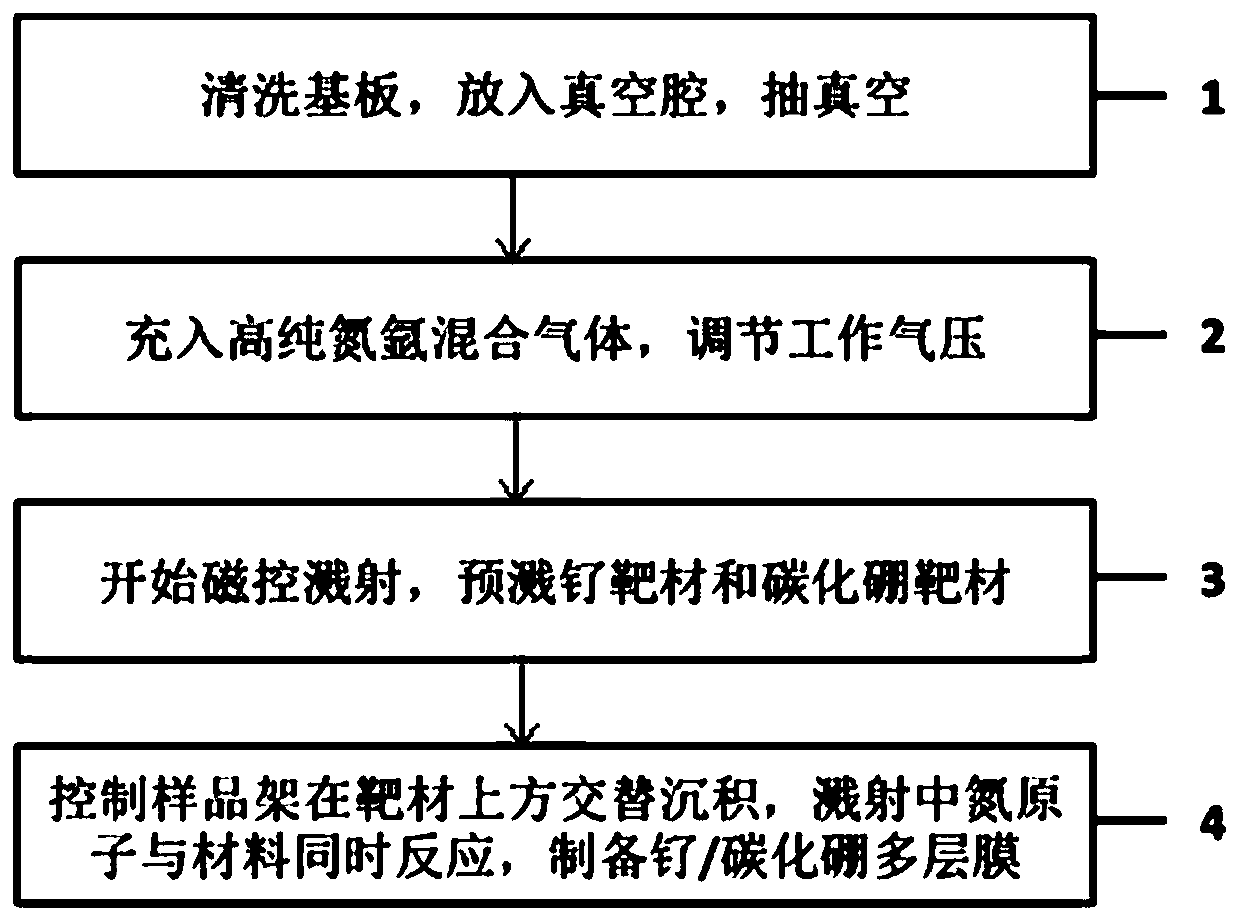

[0027] The present embodiment provides a kind of preparation method of the ruthenium / boron carbide multilayer film reflector of low stress high reflectivity that monochromator uses, as figure 1 shown, including the following steps:

[0028] In step 1, the substrate is cleaned, dried with nitrogen gas and placed on the sample holder in the coating sputtering chamber. The surface roughness of the substrate is 0.18nm. Vacuumize the coating sputtering chamber to form a sputtering coating vacuum chamber.

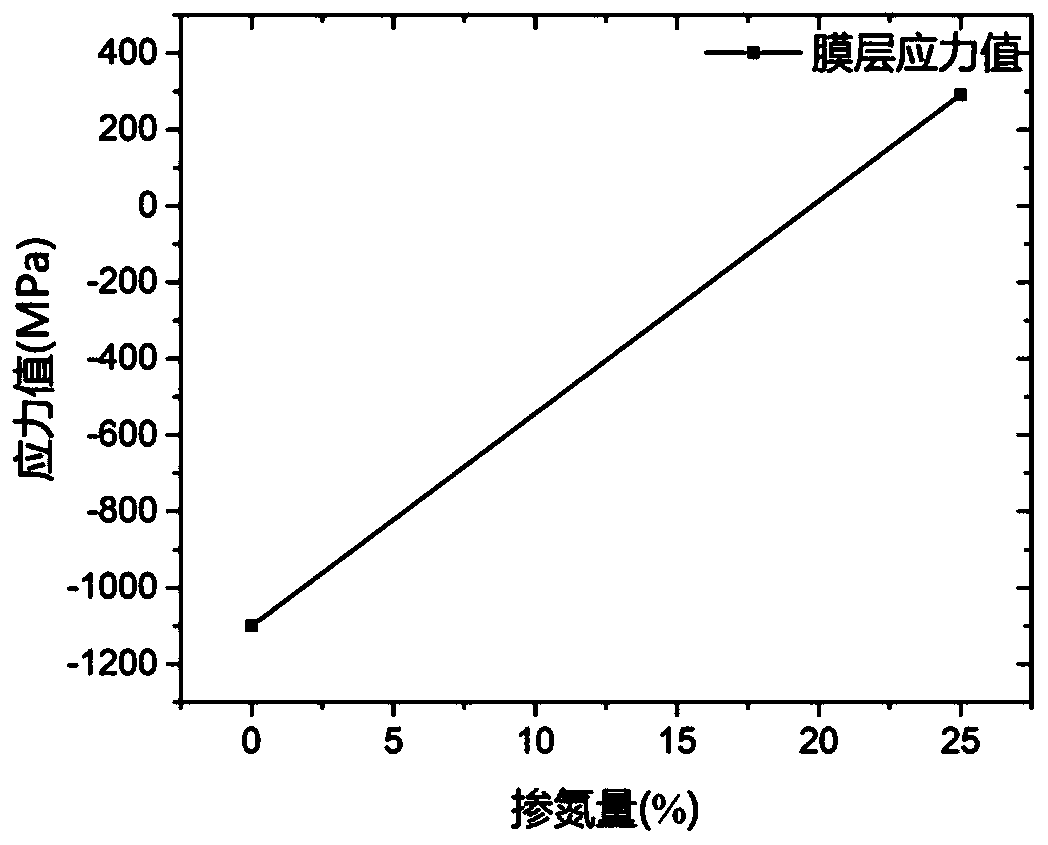

[0029] In step 2, the sputtering gas mixed with argon and nitrogen is filled into the sputter coating vacuum chamber, the purity of argon and nitrogen is higher than 99.99%, and the mixing ratio of argon and nitrogen is 25.0%. The mixed sputtering gas is filled into the sputtering coating vacuum chamber through the flow meter and the pipeline. The diameter of the cavity is 0.5m-1.0m, the height is 0.5m-1.0m, and the flow rate of the mixed sputtering gas is kept between 6.0sccm-...

Embodiment 2

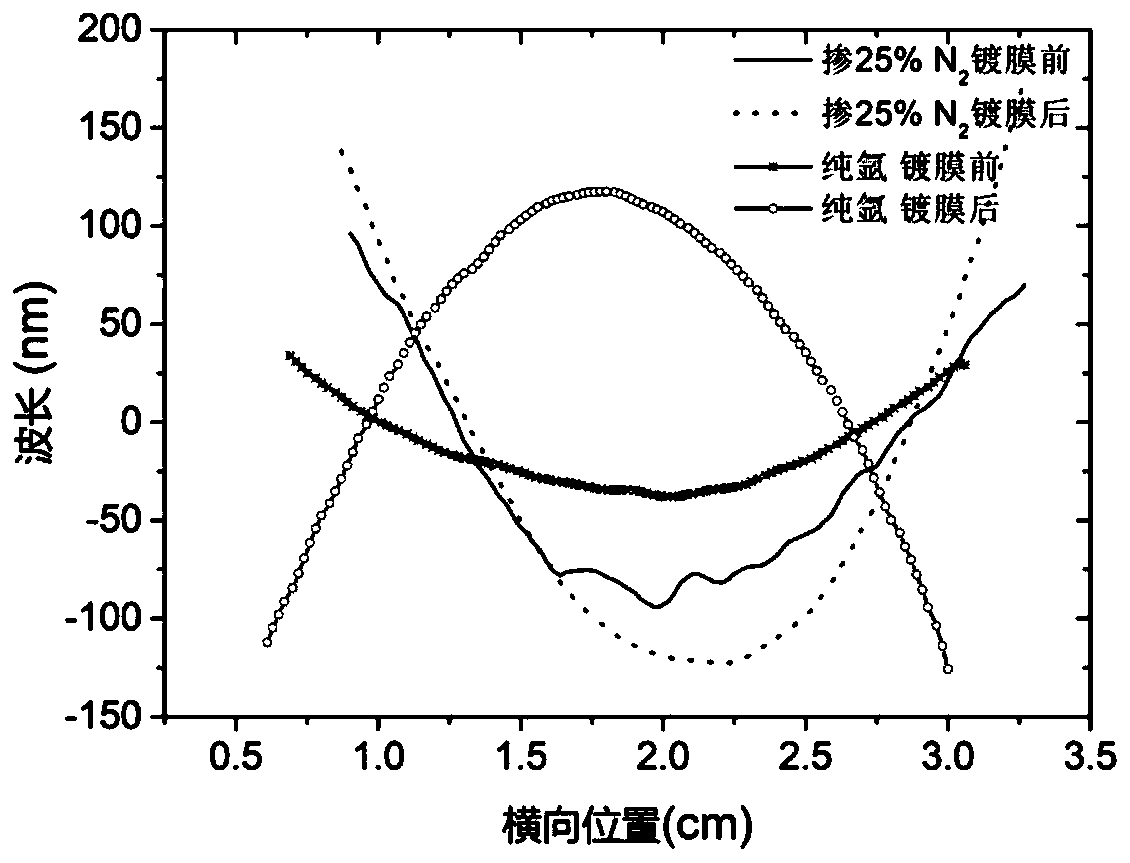

[0036] In this example, the mixing ratio of argon and nitrogen in Step 2 of Example 1 was changed from 25.0% to 16.0%, and other preparation processes and parameters were the same as in Example 1. The experimental results show that the stress of the film layer is greatly reduced, the reflectivity is greatly improved, and the structural quality of the multilayer film is greatly improved.

Embodiment 3

[0038] In this example, the mixing ratio of argon and nitrogen in Step 2 of Example 1 was changed from 25.0% to 30.0%, and other preparation processes and parameters were the same as in Example 1. The experimental results show that the stress of the film layer is greatly reduced, the reflectivity is greatly improved, and the structural quality of the multilayer film is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com