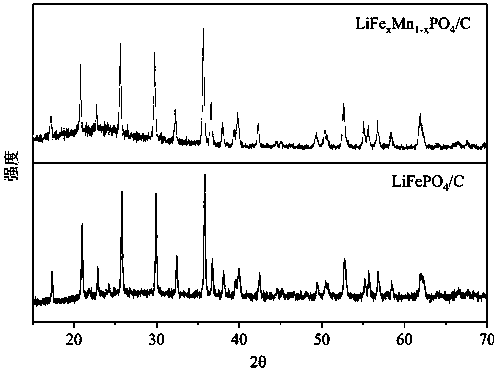

Manganese-doped regeneration lithium iron phosphate positive electrode material and method for preparing same

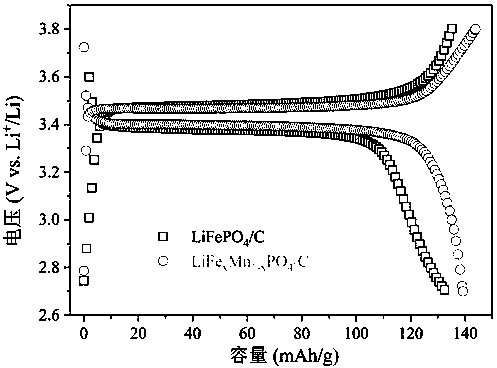

A positive electrode material, lithium iron phosphate technology, applied in the field of high-performance manganese-doped regenerated lithium iron phosphate positive electrode material and its preparation, can solve the problem of unknown regeneration process, failure to achieve commercial LiFePO4 positive electrode, and unsatisfactory product performance, etc. problems, to achieve the effects of easy amplification, narrow particle size distribution, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a manganese-doped regenerated lithium iron phosphate cathode material. It includes the following steps:

[0033] 1) The positive electrode material of the waste lithium iron phosphate battery was calcined at 300°C for 10 hours in an air atmosphere, then peeled off from the positive electrode current collector, and passed through a 200-mesh (0.074mm) sieve to obtain the waste positive electrode material;

[0034] 2) According to the element content in the waste positive electrode material, supplementary addition of lithium source lithium carbonate, iron source iron nitrate, manganese source manganese nitrate and phosphorus source ammonium dihydrogen phosphate, so that lithium carbonate, iron nitrate, manganese nitrate and ammonium dihydrogen phosphate The final molar ratio is 1.05:0.99:0.01:1. At the same time, add carbon source citric acid according to 20% of the theoretical output of lithium iron phosphate, and then add the material (the material...

Embodiment 2

[0038] A method for preparing a manganese-doped regenerated lithium iron phosphate cathode material. It includes the following steps:

[0039] 1) The positive electrode material of the waste lithium iron phosphate battery was calcined at 350°C in an air atmosphere for 8 hours, then peeled off from the positive electrode current collector, and passed through a 200-mesh (0.074mm) sieve to obtain the waste positive electrode material;

[0040] 2) According to the content of elements in the waste positive electrode material, add lithium hydroxide as lithium source, ferrous oxalate as iron source, manganese acetate as manganese source and diammonium hydrogen phosphate as phosphorus source to make lithium hydroxide, ferrous oxalate, manganese acetate, phosphoric acid The final molar ratio of diammonium hydrogen is 1.05:0.97:0.03:1, and at the same time add carbon source sucrose according to 10% of the theoretical output of lithium iron phosphate, and then add materials (the material...

Embodiment 3

[0044] A method for preparing a manganese-doped regenerated lithium iron phosphate cathode material. It includes the following steps:

[0045] 1) The positive electrode material of the waste lithium iron phosphate battery was calcined at 400°C for 5 hours in an air atmosphere, then peeled off from the positive electrode current collector, and passed through a 500 mesh (0.031mm) sieve to obtain the waste positive electrode material;

[0046] 2) According to the element content in the waste positive electrode material, add lithium oxalate from lithium source, iron oxide from iron source, manganese nitrate from manganese source, and phosphoric acid from phosphorus source, so that the final molar ratio of lithium oxalate, iron oxide, manganese nitrate, and phosphoric acid is 1.05: 0.95:0.05:1, at the same time add carbon source glucose according to 5% of the theoretical output of lithium iron phosphate, and then add materials (the materials refer to waste positive electrode materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com