Continuous production method for hydroxyethyl methylacrylate

A technology of hydroxyethyl methacrylate and methacrylic acid, which is applied in the field of continuous production of hydroxyethyl methacrylate, can solve the problems of long synthesis cycle, high toxicity of chlorohydrin, and high technical level requirements, and reduce the loss of raw materials , Reduce energy consumption, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

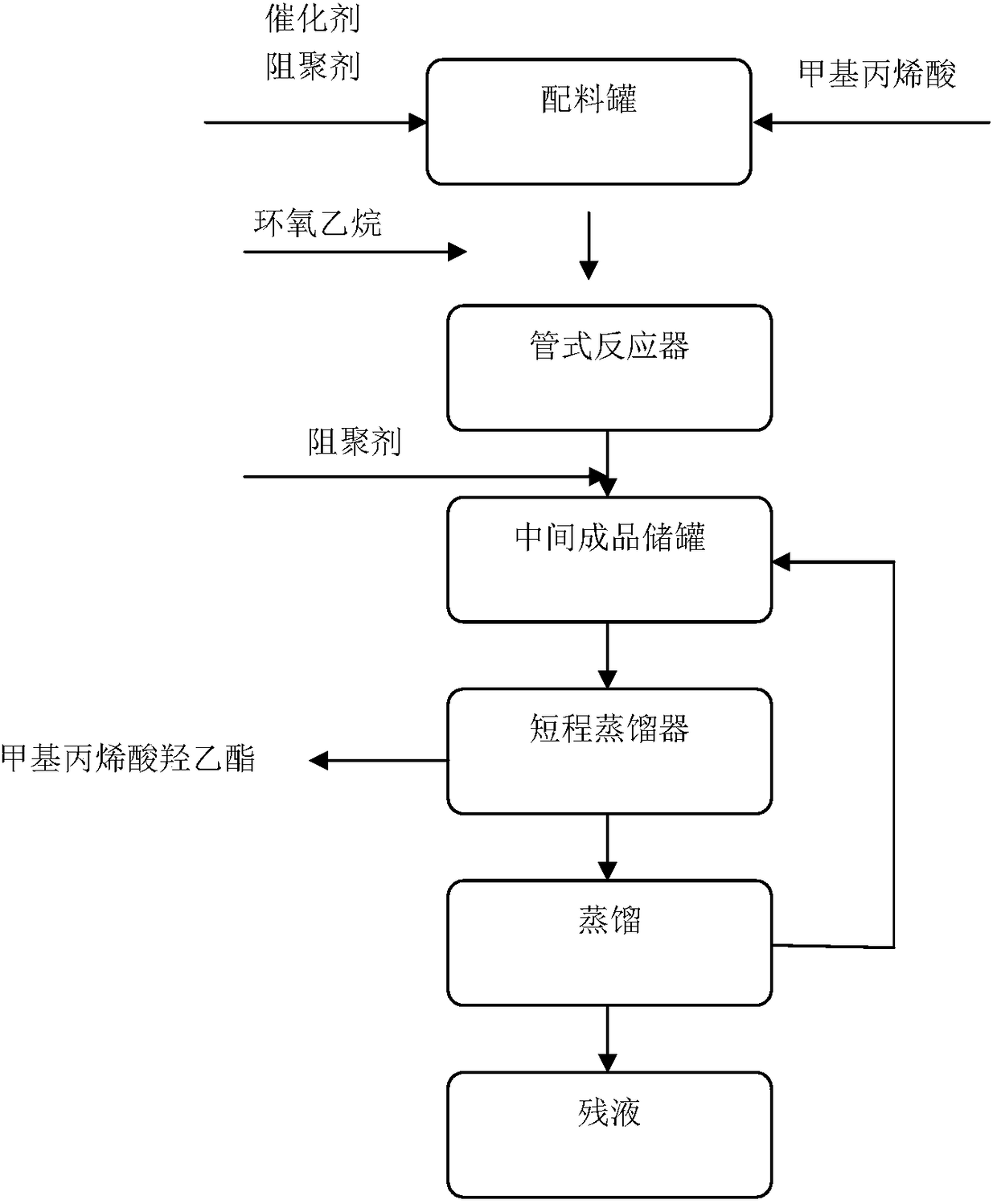

[0019] like figure 1 As shown, methacrylic acid, catalyst ferric chloride and polymerization inhibitor ZJ-705 enter the tubular reactor at a certain flow rate controlled by shielded pumps, regulating valves, and mass flow meters through the batching tank; a circulating water coil is installed in the batching tank , to cool down with circulating water to prevent the reaction of ethylene oxide and methacrylic acid under the action of a catalyst when the temperature exceeds 40°C, and the methacrylic acid cycle is formed by returning the tail pipe of the shielded pump to the batching tank to ensure the temperature of the material in the batching tank. Feed ethylene oxide into the tubular reactor, carry out ring-opening reaction at 80°C and 0.25MPa, and continuously react to generate hydroxyethyl methacrylate. A thermometer is set on the tubular reactor to interlock with the shell-side circulating water to control the temperature of the circulating water in the reactor, stabilize t...

Embodiment 2

[0021] Hydroxyethyl methacrylate is produced by the method of Example 1, the difference is only: ring-opening reaction is carried out at 60°C and 0.1MPa, the mass ratio of methacrylic acid to ethylene oxide is 6:4, and the catalyst is chlorinated The addition of iron is 0.4wt% of the gross weight of methacrylic acid and oxirane, and the addition of polymerization inhibitor ZJ-705 is 0.1wt% of the gross weight of methacrylic acid and oxirane in the batching tank, The addition amount of polymerization inhibitor ZJ-705 in the storage tank of the intermediate product is 0.05wt% of the total weight of methacrylic acid and ethylene oxide.

Embodiment 3

[0023] Hydroxyethyl methacrylate is produced by the method of Example 1, the difference is only: ring-opening reaction is carried out at 70°C and 0.75MPa, the mass ratio of methacrylic acid to ethylene oxide is 8:4, and the catalyst is chlorinated The addition of iron is 0.9wt% of the gross weight of methacrylic acid and oxirane, and the addition of polymerization inhibitor ZJ-705 is 0.5wt% of the gross weight of methacrylic acid and oxirane in the batching tank, The addition amount of polymerization inhibitor ZJ-705 in the storage tank of the intermediate product is 0.3wt% of the total weight of methacrylic acid and ethylene oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com