Method for synchronously extracting tungsten, aluminum, sodium and iron from tungsten slag and red mud

A technology of simultaneous extraction and red mud is applied in the field of metallurgical waste slag treatment and waste resource reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

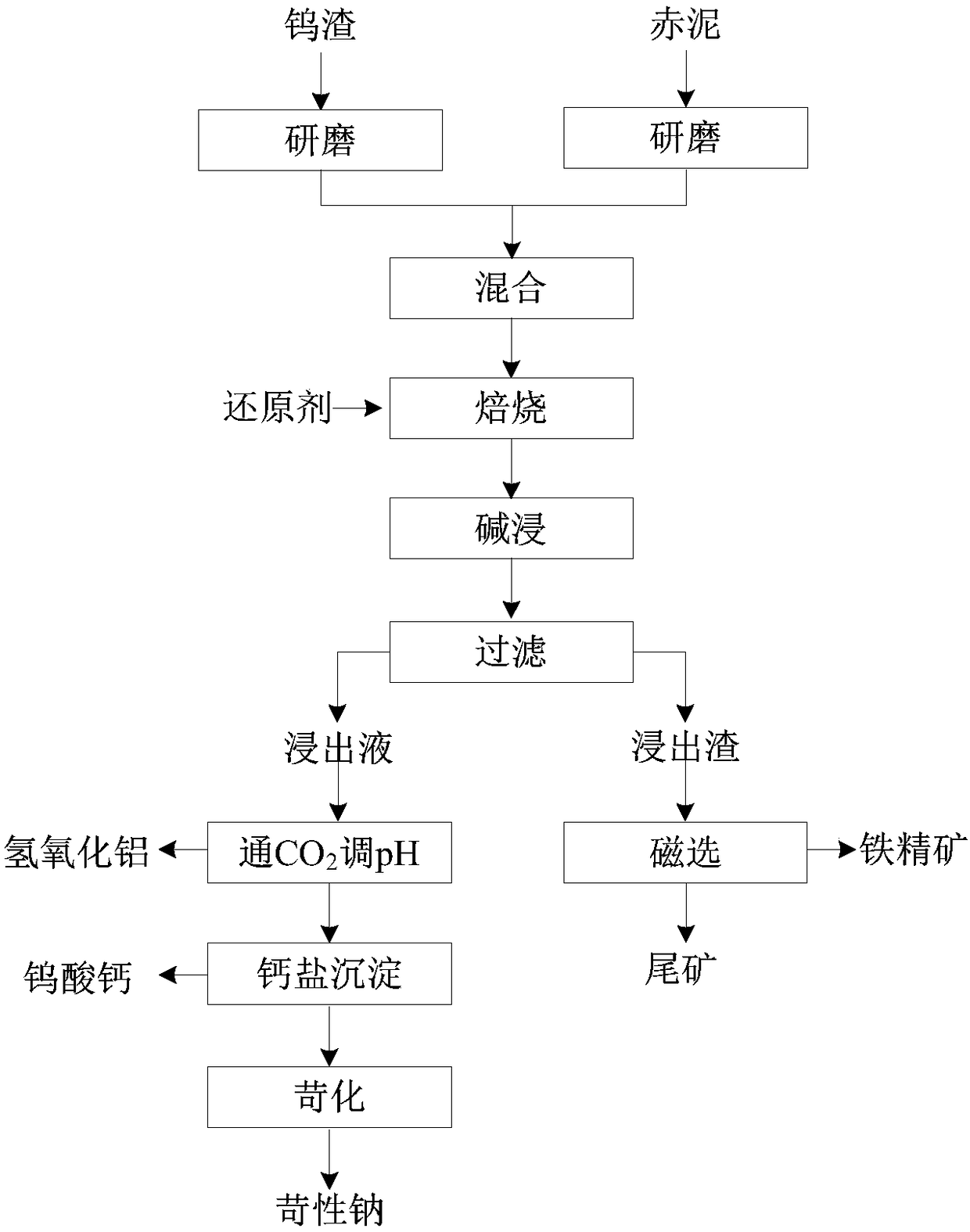

Method used

Image

Examples

Embodiment 1

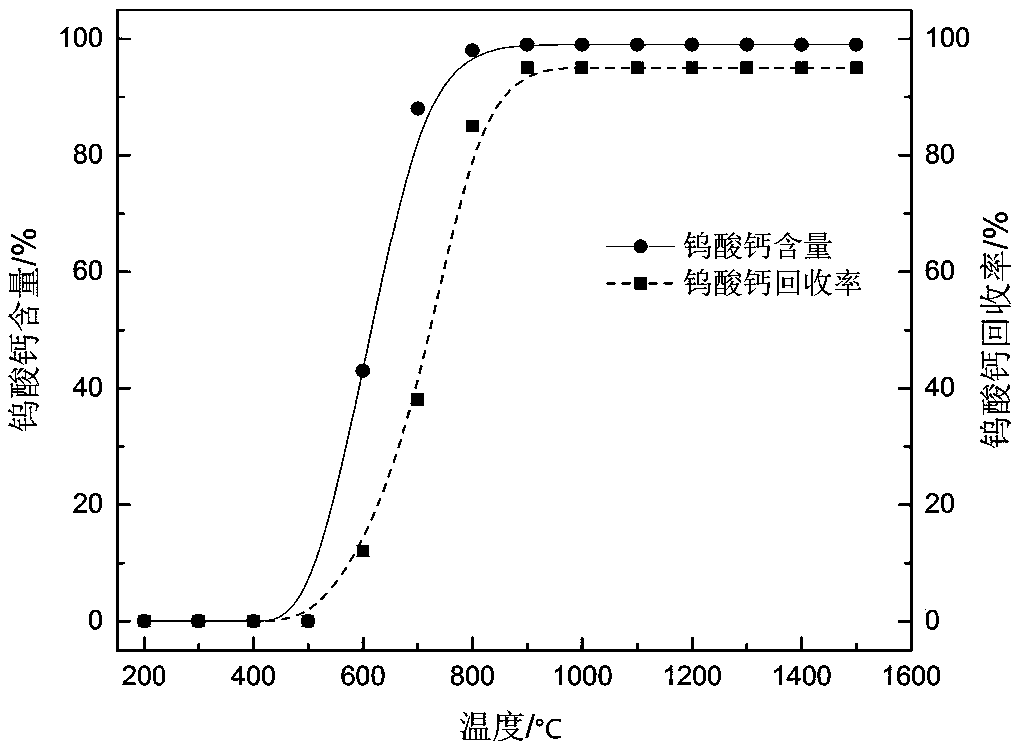

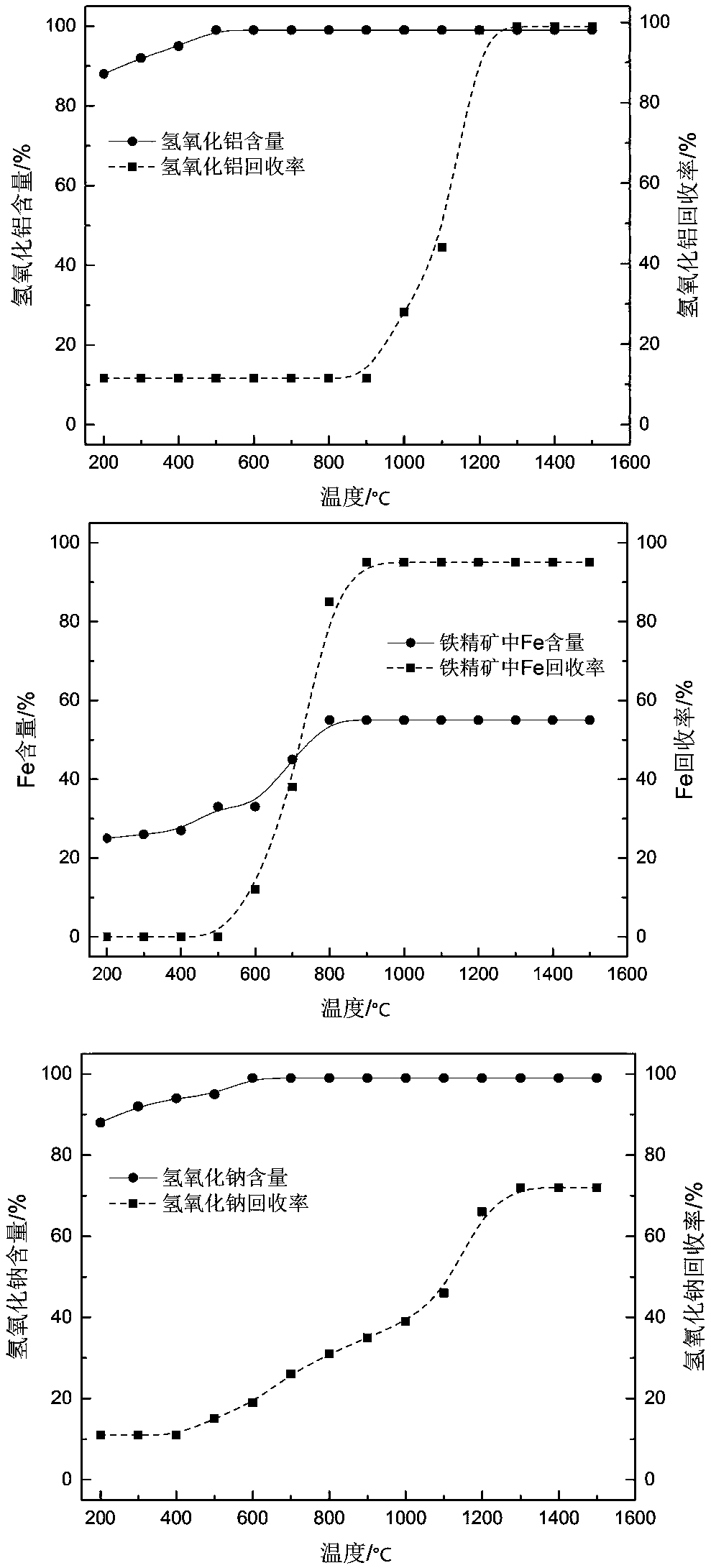

[0033] Take a WO 3 Grind the tungsten slag with 1.1% content of soda pressure cooking to less than 45μm, and take another Al 2 o 3 The content is 8.5%, Na 2 The red mud with O content of 11% and Fe content of 18% is ground to less than 45 μm, and the two ground materials are fully mixed according to the ratio of tungsten slag: red mud = 1:2, and 50 mL of CO gas is introduced / min Roast at 1200°C for 200 minutes, grind the roasted material to less than 45μm and put it into 0.5mol / L sodium hydroxide solution for leaching. According to the liquid-solid ratio of 5:1, the leaching temperature is 90°C, the leaching stirring time is 20 minutes, and filter , the filter residue is magnetically separated by a high-gradient magnetic separator with a magnetic field strength of 1T to obtain iron concentrate containing Fe55%, and the filtrate is passed into CO 2 Adjust the pH of the gas to 7 and filter to obtain aluminum hydroxide solids with a purity of 98.2%. Continue to slowly add cal...

Embodiment 2

[0035] Take the fumed slag after fuming and roasting of cassiterite in a certain place, which contains WO 3 4.4%, another place Al 2 o 3 The content is 5.3%, Na 2 O content is 18.5%, and Fe content is 22.3% fly ash red mud slag after aluminum extraction, after it is ground to be less than 45 μ m, the material is fully mixed according to the ratio of tungsten slag:red mud=1:3, add total The charcoal powder with 1 / 10 of the slag content is roasted at 1000°C for 60 minutes. The roasted material is ground to less than 45 μm and then placed in an aqueous solution for leaching. According to the liquid-solid ratio of 10:1, the leaching temperature is 85°C, and the leaching and stirring time is 30 minutes. Filter. The filter residue is magnetically separated by a high-gradient magnetic separator with a magnetic field strength of 2T to obtain an iron concentrate containing Fe65.6%, and the filtrate is passed into CO 2Adjust the pH of the gas to 7.5 and filter to obtain aluminum hydr...

Embodiment 3

[0037] Take the leaching residue after acid leaching tungsten in a certain place, which contains WO 3 2.6%, another place Al 2 o 3 The content is 20.1%, Na 2 O content is 36.6%, and Fe content is the sodium silicon slag of 15.1%, after it is ground to less than 45 μ m, the material is fully mixed according to the ratio of tungsten slag: sodium silicon slag=1:0.5, feeds water gas 100mL / min in Roast at 850°C for 60 minutes, grind the roasted material to less than 45 μm and put it into 0.1mol / L sodium carbonate solution for leaching. According to the liquid-solid ratio of 3:1, the leaching temperature is 90°C, and the leaching stirring time is 30 minutes. Filter and pass the filter residue through The high gradient magnetic separator with a magnetic field strength of 2.5T obtained iron concentrate containing 62.1% Fe by magnetic separation, and CO was passed into the filtrate 2 Adjust the pH of the gas to 6.5 and filter to obtain aluminum hydroxide solids with a purity of 99.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com