Formula of radiation shielding lead alloy

A radiation shielding and lead alloy technology, applied in the field of alloy materials, can solve the problems of reduced toughness of boron-aluminum alloys, affecting shielding effect, and large material brittleness, so as to enhance plasticity and toughness, overcome secondary bremsstrahlung, and meet structural requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention provides a radiation shielding lead alloy formula. Specifically, the lead alloy of the present invention is used to produce a radiation shielding material with excellent performance. The radiation shielding material is a multilayer special-shaped mosaic structure, and the first layer is a molding property. Excellent first lead alloy metal layer. The first lead alloy metal layer contains lead, tungsten, boron, aluminum, titanium, copper, nickel, and molybdenum. Specifically, the composition of the first lead alloy metal layer The weight percentages are as follows:

[0025] Tungsten W 0.5% to 1.2%, preferably 0.8%;

[0026] Boron B is 0.1% to 1%, preferably 0.3%;

[0027] Aluminum 0.013%~0.027%, preferably 0.021%;

[0028] Titanium Ti 0.009% to 0.016%, preferably 0.011%;

[0029] Copper Gu 0.1%~0.23%, preferably 0.18%;

[0030] Nickel Ni 0.08%~0.13%, preferably 0.14%;

[0031] Mo 0.006%~0.019%, preferably 0.012%;

[0032] For the remaining amount of reduced lea...

Embodiment 2

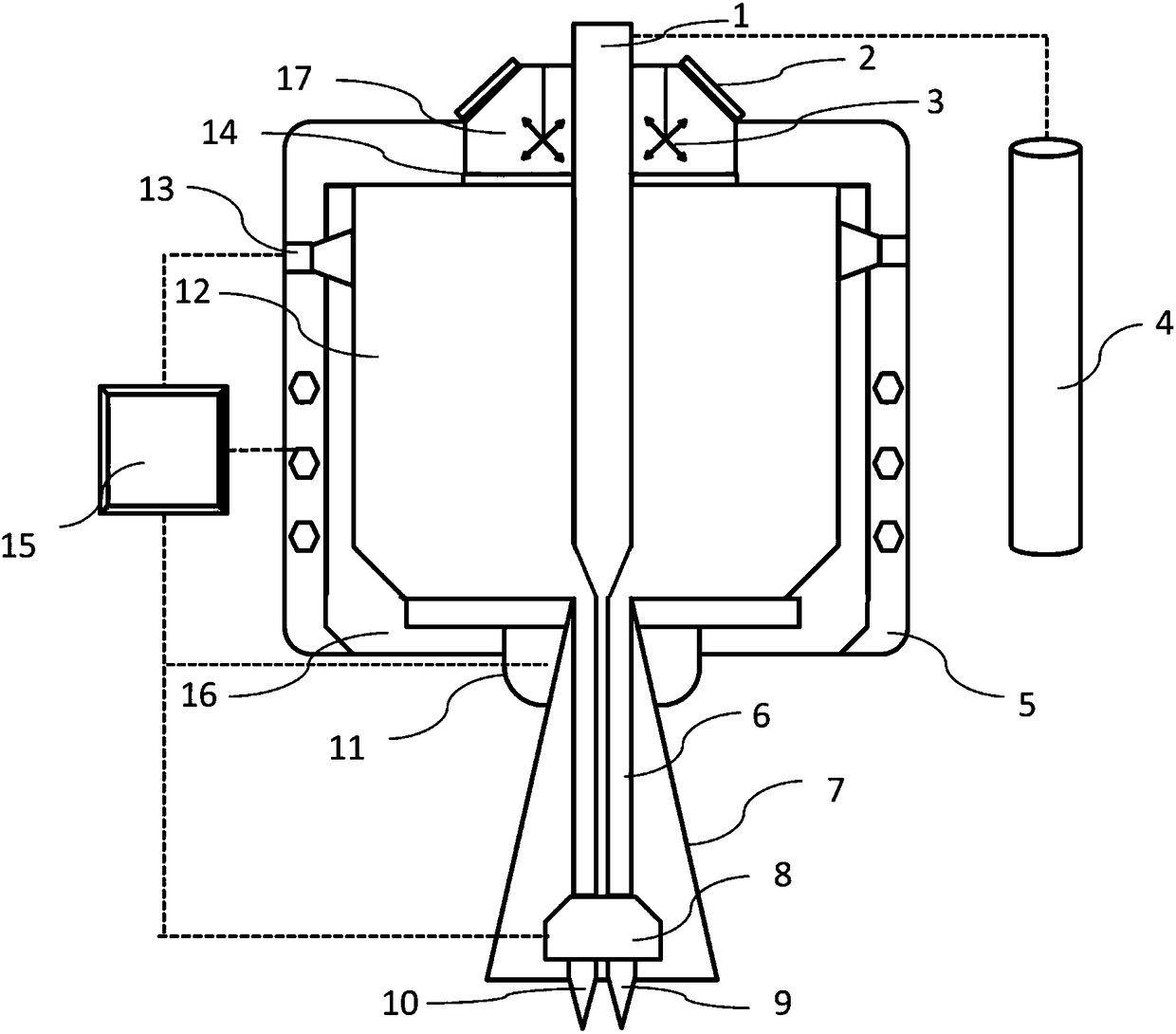

[0041] The lead alloy metal layer is prepared by a high-density intelligent spray deposition gun. The high-density intelligent spray deposition gun includes a gas delivery tube 1, a primary feed port 2, a stirrer 3, an inert gas generator 4, and an induction heating furnace 5. , Molten metal transfer pipe 6, inert gas protective cover 7, spray gun base 8, first spray gun 9, second spray gun 10, pressure generator 11, graphite crucible 12, temperature sensor 13, secondary feed port 14, intelligent control 器15, the deposition gun body 16, the mixing chamber 17. The first-level feed port 2 is located on the top of the deposition gun body 16, and there are two in total, which are connected to the second-level feed port 14, which is located inside the deposition gun body 16, and is connected to the graphite. The crucible 12 is provided with two graphite crucibles 12 inside, the bottom of the graphite crucible 12 is connected with a molten metal transfer pipe 6, and a rotary spray gun...

Embodiment 3

[0043] First, glue the third and fourth layers of special-shaped radiation shielding materials such as flat panels or arc-shaped panels to form an integrated structure, and fix them on the three-dimensional intelligent motion platform. Then, the metals required for the second lead alloy metal layer are mixed according to the composition ratio and then injected into the stirring chamber. After stirring, they are injected into the graphite crucible. The metal liquid mixture flows into the spray gun through the molten metal transfer tube, and is atomized by the high-pressure gas into a uniform droplet spray. , The movement mode of the three-dimensional intelligent motion platform is controlled by the intelligent controller. According to the requirements of the cooling speed, it moves according to a certain rule. The injection density is controlled by the intelligent controller. The injection density composite function: m(r)=exp(-b× r 2 )×β, where m(r) is the spray density function,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com