Polyester fabric antistatic agent and application method thereof

A polyester fabric and antistatic agent technology, applied in the field of textile processing, can solve the problems of inability to guarantee the long-term antistatic use quality of polyester products, poor antistatic stability, and decreased antistatic ability, so as to avoid antistatic performance and improve antistatic performance. Electrostatic performance, enhanced stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The polyester fabric antistatic agent is composed of the following raw materials in weight percentage:

[0021] Acrylamide-diacetone acrylamide copolymer 4%, potassium cetyl phosphate 2%, PEG-60 hydrogenated castor oil 1%, ethylene glycol diglycidyl ether 1%, disodium lauryl sulfosuccinate 0.5 %, triethylene glycol diisocaprylate 0.5%, sodium lauroyl glutamate 0.5%, hydrolyzed polymaleic anhydride 0.3%, zinc isooctanoate 0.3%, the balance of water.

[0022] Acrylamide-diacetone acrylamide copolymer is synthesized using acrylamide and diacetone acrylamide as monomers, potassium persulfate as initiator, and water as the reaction solvent. The molar ratio of acrylamide to diacetone acrylamide is 2.5 :1, the amount of initiator is 0.2wt%, and the reaction temperature is 35°C.

[0023] The method of using the antistatic agent for polyester fabrics includes the following steps:

[0024] (1) Immersion: Immerse the polyester fabric in an antistatic agent. The temperature of the antista...

Embodiment 2

[0030] The polyester fabric antistatic agent is composed of the following raw materials in weight percentage:

[0031] Acrylamide-diacetone acrylamide copolymer 5%, potassium cetyl alcohol phosphate 2%, PEG-60 hydrogenated castor oil 1%, ethylene glycol diglycidyl ether 1%, disodium lauryl sulfosuccinate 0.5 %, triethylene glycol diisocaprylate 0.5%, sodium lauroyl glutamate 0.5%, hydrolyzed polymaleic anhydride 0.3%, zinc isooctanoate 0.3%, the balance of water.

[0032] Acrylamide-diacetone acrylamide copolymer is synthesized using acrylamide and diacetone acrylamide as monomers, potassium persulfate as initiator, and water as the reaction solvent. The molar ratio of acrylamide to diacetone acrylamide is 2.5 :1, the amount of initiator is 0.2wt%, and the reaction temperature is 35°C.

[0033] The method of using the antistatic agent for polyester fabrics includes the following steps:

[0034] (1) Immersion: Immerse the polyester fabric in an antistatic agent. The temperature of the...

Embodiment 3

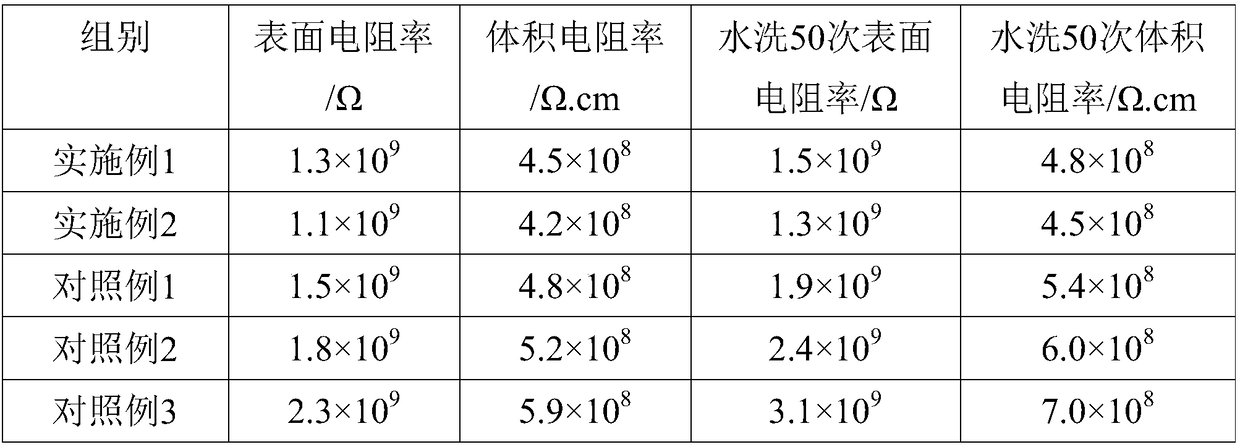

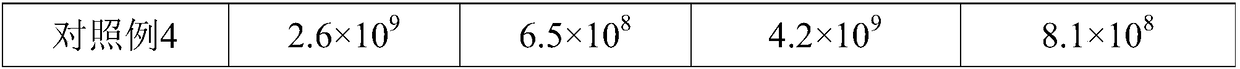

[0074] Example 1-2 and Comparative Example 1-4 were used to carry out antistatic finishing on polyester fabrics of the same specification produced in the same batch, and the surface resistivity, volume resistivity and water washing of the finished polyester fabric were measured with reference to GB / T16801-2013 The surface resistivity and volume resistivity after 50 times are shown in Table 1.

[0075]

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com