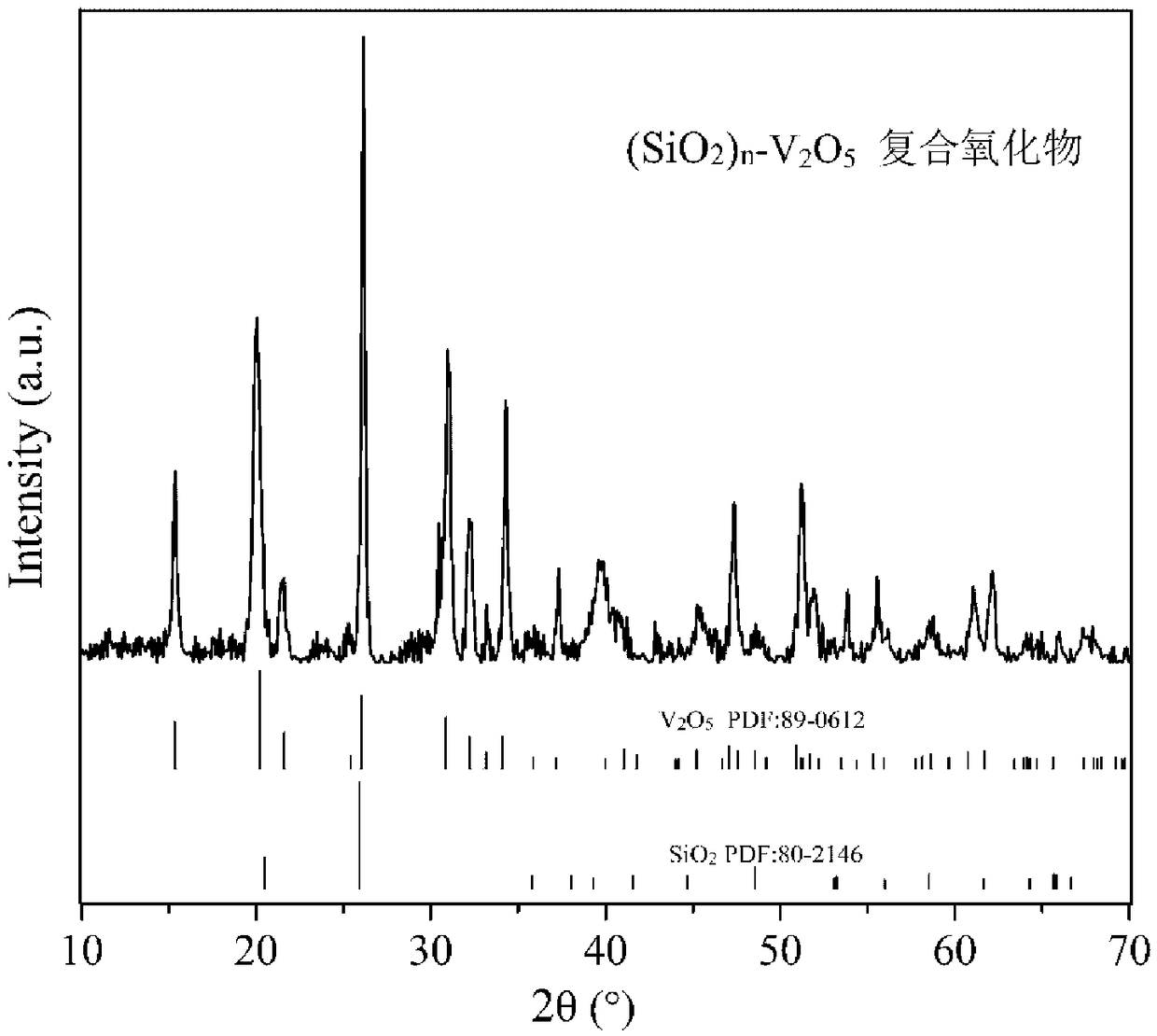

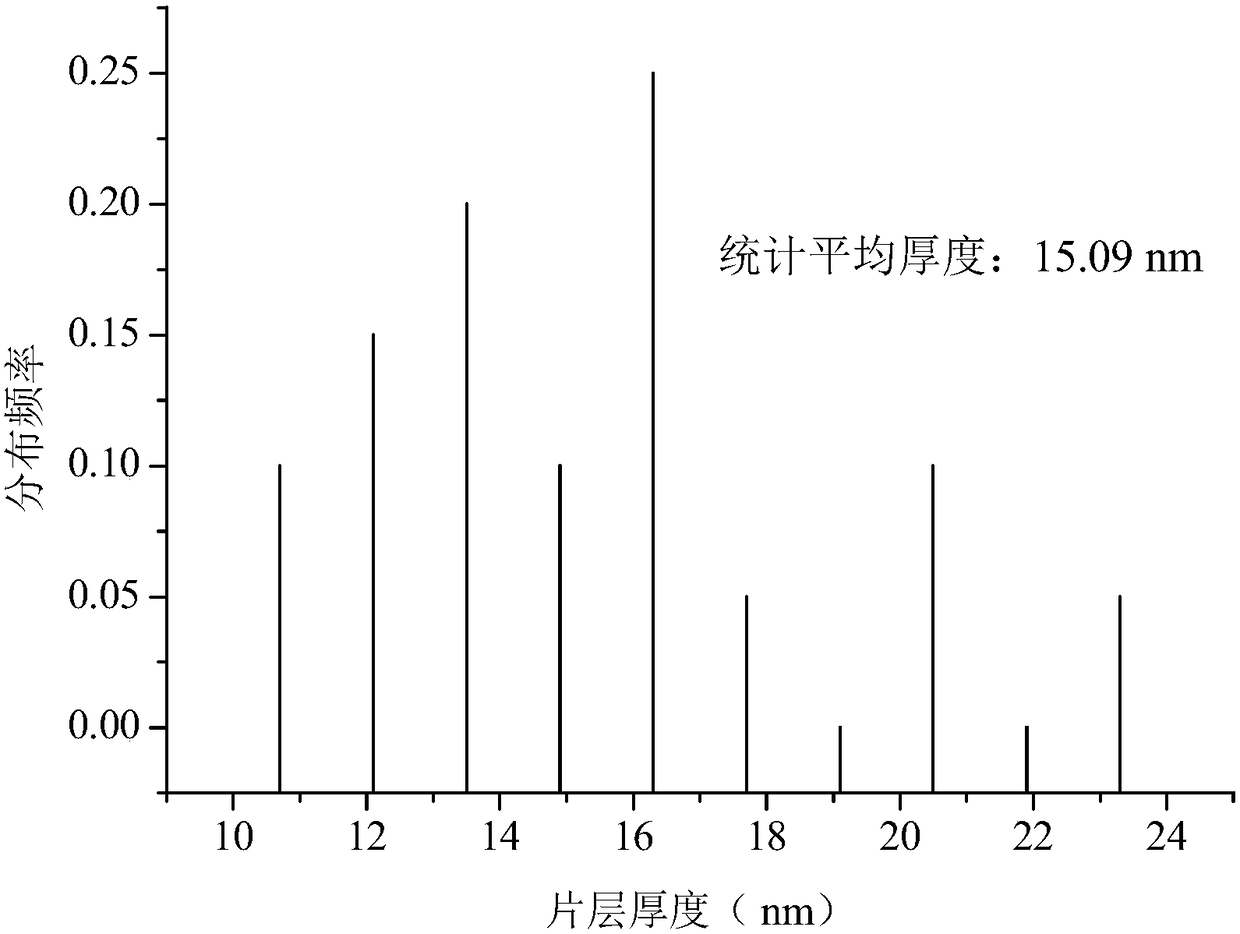

Silicon-vanadium composite oxide and preparation method thereof

A composite oxide and chemical technology, applied in the direction of vanadium oxide, silicon oxide, silicon dioxide, etc., to achieve the effect of high thermal stability, large specific surface area, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In order to obtain the non-metal-metal oxide phase structure with the above-mentioned uniform structure, the present invention adopts a one-step hydrothermal synthesis method in which a complexing agent and a surfactant are combined: a certain amount of ammonium metavanadate powder and ethyl orthosilicate are respectively Dissolve in aqueous solution and mix, then add a certain amount of complexing agent oxalic acid and surface-active ammonium lauryl sulfate, and move it into a reaction kettle (hydrothermal reaction kettle or high-pressure hydrothermal kettle, etc.) for one-time hydrothermal reaction; take out Afterwards, the precursor is obtained by filtering, washing, and drying, and the precursor is placed in a heating furnace (muffle furnace, etc.) and roasted for a certain period of time to obtain a silicon-vanadium composite oxide with a curd layer structure. The specific preparation methods include:

[0035] According to (SiO 2 ) n VO m The preset values of ...

Embodiment 1

[0043] Example 1 is as follows:

[0044](1) Weigh 2.73g of tetraethyl orthosilicate and 4.0g of ammonium metavanadate, and dissolve them in 100mL of distilled water separately under the condition of stirring at 50°C to prepare an aqueous solution of ethyl orthosilicate and ammonium metavanadate . Mix the two aqueous solutions prepared above, stir fully at 50°C, then add 4.3g oxalic acid dihydrate as a complexing agent, and stir for 2 hours; then add 6.2g of 30wt% ammonium lauryl sulfate aqueous solution, The stirring reaction was continued at 50°C for 24 hours.

[0045] (2) The reacted solution was transferred into a high-pressure hydrothermal kettle, aged at 180°C for 24 hours, and then the product was taken out, centrifuged, washed, and dried in an oven at 60°C for 8 hours to obtain a solid precursor. Place the obtained precursor in a muffle furnace, raise the temperature to 450°C at a rate of 2°C / min, bake at 450°C for 6 hours, and cool to obtain the composite with this s...

Embodiment 2

[0049] (1) Weigh 2.73 g of ethyl orthosilicate and 2 g of ammonium metavanadate, and dissolve them in 70 mL of distilled water separately under the condition of stirring at 50° C. to prepare an aqueous solution of ethyl orthosilicate and ammonium metavanadate. Mix the two aqueous solutions prepared above, stir fully at 50°C, then add 2.15g oxalic acid dihydrate as a complexing agent, and stir for 2 hours; then add 4.0g of 30wt% lauryl ammonium sulfate aqueous solution, The stirring reaction was continued at 50°C for 24 hours.

[0050] (2) The reacted solution was transferred into a high-pressure hydrothermal kettle, aged at 160°C for 24 hours, and then the product was taken out, centrifuged, washed, and dried in an oven at 60°C for 12 hours to obtain a solid precursor. Place the obtained precursor in a muffle furnace, raise the temperature to 500°C at a rate of 2°C / min, bake at 500°C for 5 hours, and cool to obtain the composite with this special structure.

[0051] The silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com