Low-density cement used for well cementation

A low-density cement and cementing technology, applied in the field of cement, can solve the problems of long thickening time, different thickening time and poor high temperature stability of cement slurry, and achieve constant density, high early strength and high high temperature stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

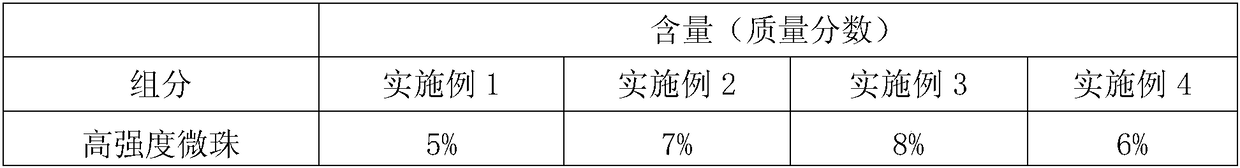

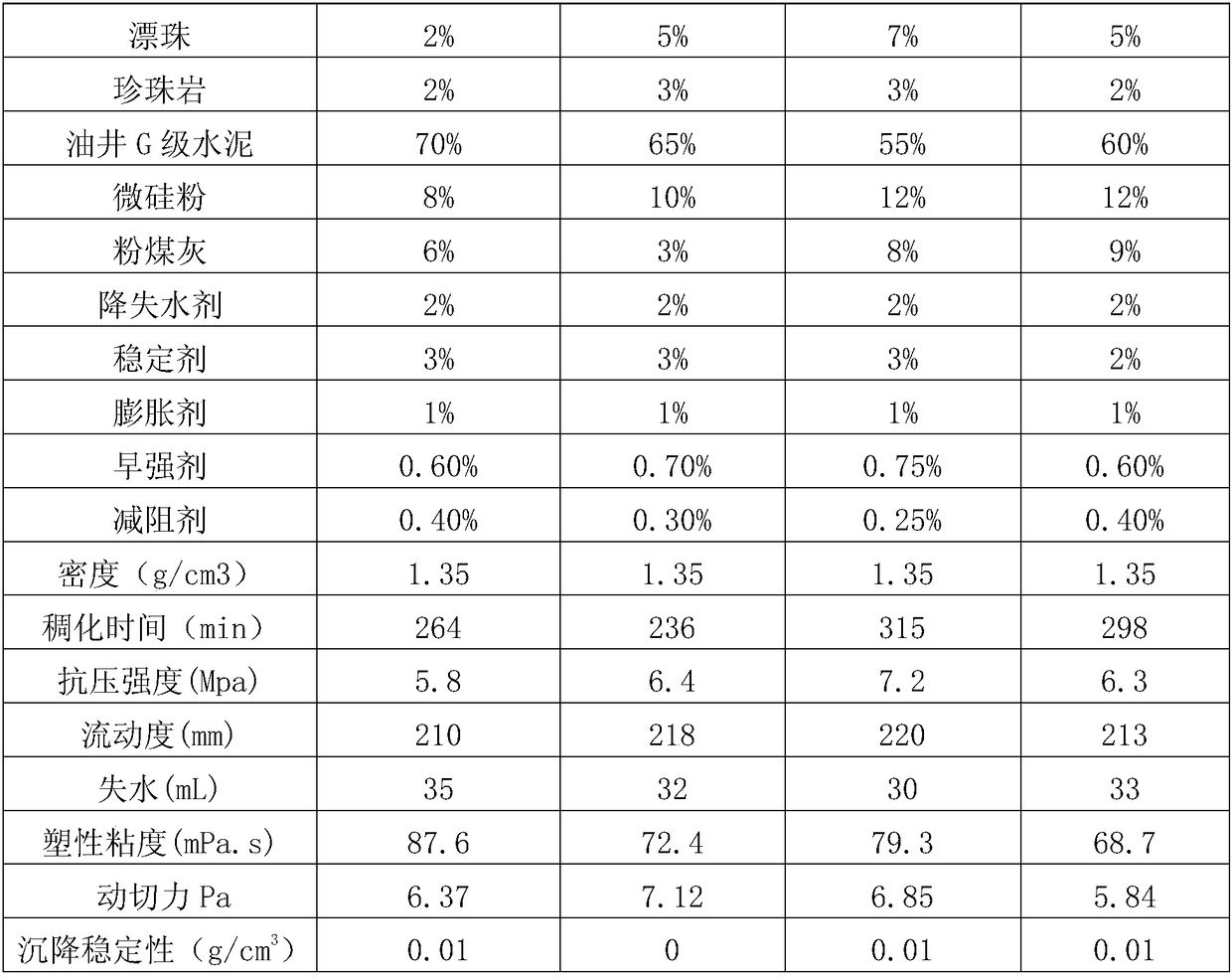

Embodiment 1

[0024] Low-density cement for well cementing, including the following components by mass fraction: high-strength microbeads 5%, floating beads 2%, perlite 2%, oil well G-grade cement 70%, microsilica fume 8%, fly ash 6% , 2% fluid loss reducer, 3% stabilizer, 1% expansion agent, 0.6% early strength agent, 0.4% drag reducer.

[0025] Further, the expansion agent includes the following components in mass fraction: 29% of potassium aluminum silicate, 47% of calcium sulfoaluminate, and 24% of superfine magnesium hydroxide.

[0026] Further, the fluid loss reducer includes the following components in mass fraction: 27% of 2-acrylamide, 39% of 2-methylpropanesulfonic acid, 7% of ammonium persulfate, 9% of sodium bisulfite, sodium hydroxide 5%, N, N-methylenebisacrylamide 13%.

[0027] Further, the early strength agent includes the following components in mass fractions: 21% potassium carbonate, 18% polyaluminum chloride, 48% sodium silicate, and 13% calcium silicate.

[0028] Furt...

Embodiment 2

[0031] Low-density cement for well cementing, including the following components by mass fraction: 7% high-strength microbeads, 5% floating beads, 3% perlite, 65% oil well G-grade cement, 10% silica fume, and 3% fly ash , 2% fluid loss reducer, 3% stabilizer, 1% expansion agent, 0.7% early strength agent, 0.3% drag reducer.

[0032] The components and contents of the expansion agent, fluid loss reducer, early strength agent, stabilizer, and drag reducer are the same as those in Example 1.

Embodiment 3

[0034] Low-density cement for well cementing, including the following components by mass fraction: high-strength microbeads 8%, floating beads 7%, perlite 3%, oil well G-grade cement 55%, microsilica fume 12%, fly ash 8% , fluid loss reducer 2%, stabilizer 3%, expansion agent 1%, early strength agent 0.75%, drag reducer 0.25%.

[0035] The components and contents of the expansion agent, fluid loss reducer, early strength agent, stabilizer, and drag reducer are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com