High-temperature high-emissivity silica brick for glass melting furnace and preparation method of high-temperature high-emissivity silica brick

A technology of glass melting furnace and high radiation rate, which is applied in the field of refractory materials, can solve the problems of reducing infrared radiation rate, achieve the effects of improving radiation matching, increasing heat utilization rate, and strengthening radiation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

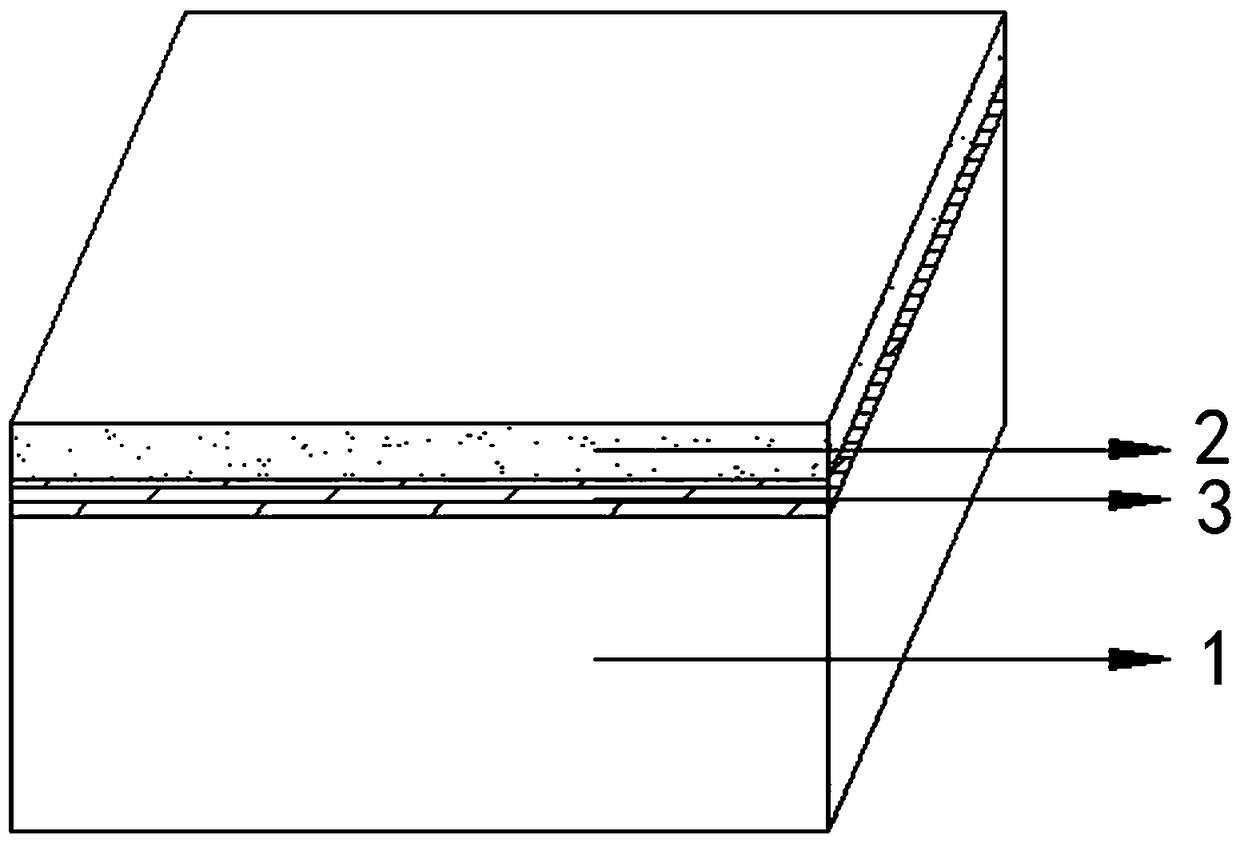

[0031] Such as figure 1 As shown, the present invention provides a high-temperature, high-emissivity silica brick for a glass melting furnace, comprising a silica brick main body 1, and the surface of the silica brick main body 1 is coated with a nano-infrared coating 2;

[0032] The weight percentage of the components contained in the main body of the silica brick is: 20% of silica with a particle size of 5-10mm, 40% of silica with a particle size of 0.5-5mm, 25% of silica powder with a particle size of 100-600μm, and 25% of silica powder with a particle size of less than 5μm Quartz powder 15%, and mineralizers accounting for 2% of the total weight of the above components, 10% composite additives and 1% silicon carbide;

[0033] The mineralizer comprises the following components by weight percentage: milk of lime 60%, iron scale 10%, boric acid 18%, lithium carbonate 9% and sodium carbonate 3%;

[0034] The composite additive comprises the following components by weight perc...

Embodiment 2

[0049] Such as figure 1 As shown, the present invention provides a high-temperature, high-emissivity silica brick for a glass melting furnace, comprising a silica brick main body 1, and the surface of the silica brick main body 1 is coated with a nano-infrared coating 2;

[0050] The weight percentage of the components contained in the main body of the silica brick is: 30% of silica with a particle size of 5-10mm, 30% of silica with a particle size of 0.5-5mm, 20% of silica powder with a particle size of 100-600μm, and silica powder with a particle size of less than 5μm. 20% quartz powder, 3% mineralizer, 7% composite additive and 2% silicon carbide accounting for the total weight of the above components;

[0051] The mineralizer comprises the following components by weight percentage: milk of lime 65%, iron scale 8%, boric acid 20%, lithium carbonate 3% and sodium carbonate 4%;

[0052]The composite additive comprises the following components by weight percentage: 12% ammoni...

Embodiment 3

[0067] Such as figure 1 As shown, the present invention provides a high-temperature, high-emissivity silica brick for a glass melting furnace, comprising a silica brick main body 1, and the surface of the silica brick main body 1 is coated with a nano-infrared coating 2;

[0068] The weight percentage of the components contained in the main body of the silica brick is: 35% of silica with a particle size of 5-10 mm, 25% of silica with a particle size of 0.5-5 mm, 15% of silica powder with a particle size of 100-600 μm, and 15% of silica powder with a particle size of less than 5 μm. 25% of quartz powder, and 3.5% of mineralizer, 6% of composite additives and 3% of silicon carbide accounting for the total weight of the above components;

[0069] The mineralizer comprises the following components by weight percentage: milk of lime 70%, iron scale 6%, boric acid 12%, lithium carbonate 4% and sodium carbonate 8%;

[0070] The composite additive comprises the following components b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com