A kind of emerald glaze craft ceramic product and its manufacturing process

A technology of craft ceramics and jade, applied to clay products, other household utensils, household utensils, etc., can solve the problems of low firing rate of jade glazed ceramics, dull colors and patterns, low radiation, etc., and achieve magnificent and delicate overall colors , The bottom glaze is transparent and bright, and has good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

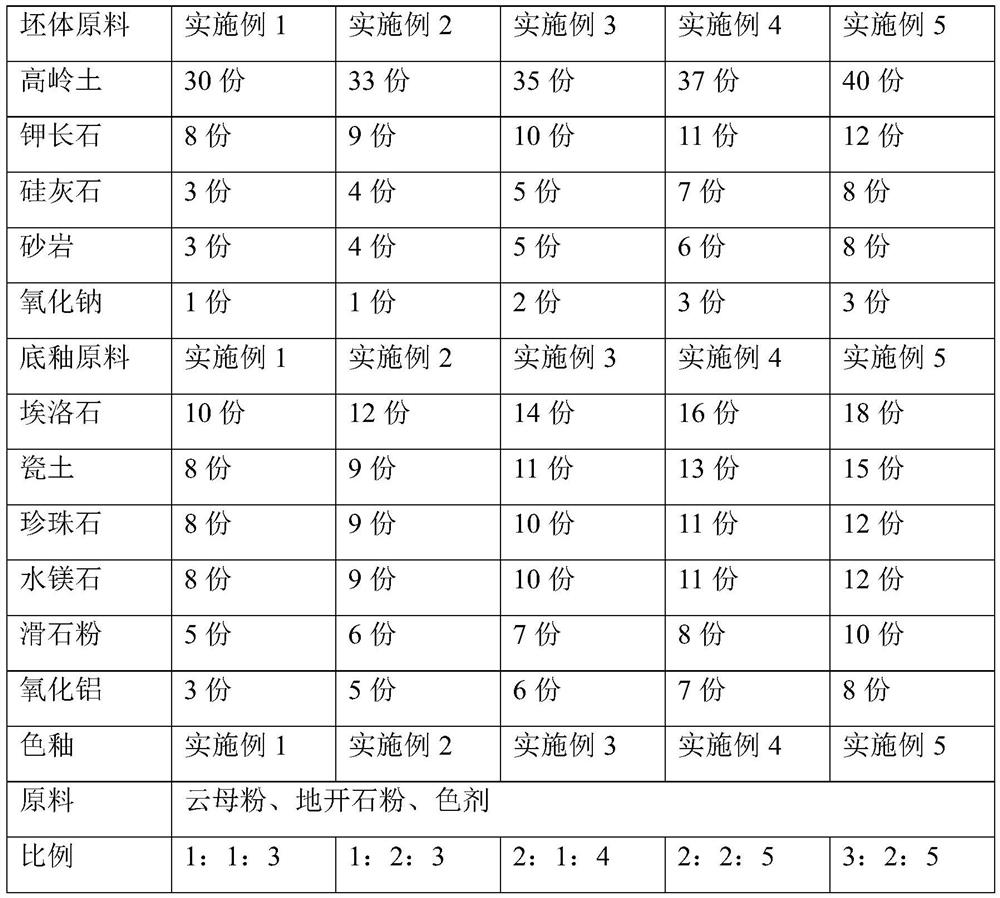

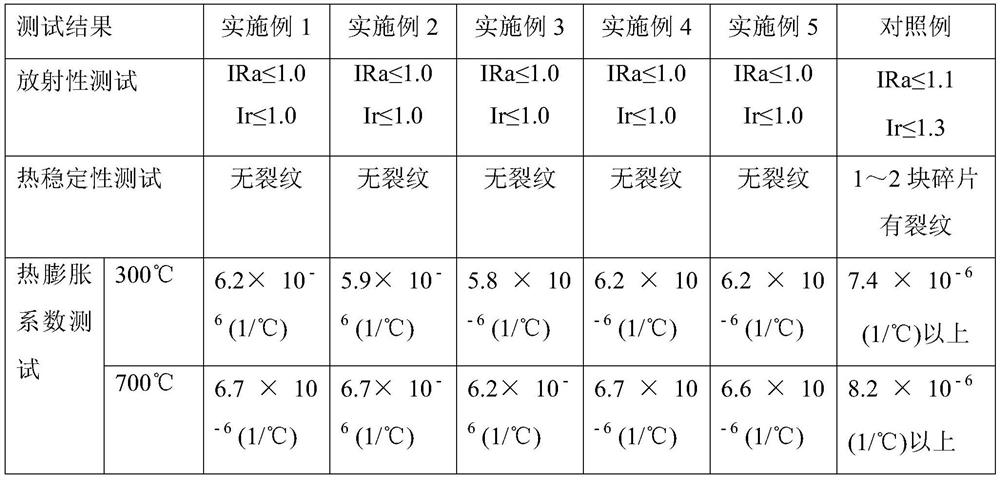

Embodiment 1

[0023] This embodiment provides a kind of emerald glaze craft ceramic product, comprises green body and the base glaze and color glaze that are applied to the surface of green body successively, and described green body comprises the raw material of following parts by weight: 30 parts of kaolin, 8 parts of potassium feldspar, 3 parts of wollastonite, 3 parts of sandstone, 1 part of sodium oxide; the bottom glaze includes the following raw materials in parts by weight: 10 parts of halloysite, 8 parts of china clay, 8 parts of pearlite, 8 parts of brucite, 5 parts of talcum powder parts, 3 parts of alumina; the color glaze raw materials include mica powder, dickite powder, and coloring agent in a weight ratio of 1:1:3, and the coloring agent is iron, manganese, nickel, copper, tin, magnesium, cobalt At least one of elemental substance or oxide.

[0024] A method for manufacturing emerald glaze craft ceramics, comprising the following steps:

[0025] Step 1, take each raw materi...

Embodiment 2

[0030] This embodiment provides a kind of emerald glaze craft ceramic product, comprising green body and base glaze and color glaze that are sequentially applied on the surface of green body, described green body includes the following raw materials by weight: described green body includes the following raw materials by weight : 33 parts of kaolin, 9 parts of potassium feldspar, 4 parts of wollastonite, 4 parts of sandstone, 1 part of sodium oxide; the bottom glaze includes the following raw materials in parts by weight: 12 parts of halloysite, 9 parts of china clay, 9 parts of pearlite part, 9 parts of brucite, 6 parts of talcum powder, and 5 parts of alumina; the colored glaze raw material includes mica powder, dickite powder, and coloring agent in a weight ratio of 1:2:3, and the coloring agent is iron, At least one of manganese, nickel, copper, tin, magnesium, cobalt element or oxide.

[0031] A method for manufacturing emerald glaze craft ceramics, comprising the followin...

Embodiment 3

[0037] This embodiment provides a kind of emerald glaze craft ceramic product, comprises green body and the ground glaze that is applied on the surface of green body successively and colored glaze, and described green body comprises the raw material of following weight parts: kaolin 35 parts, potassium feldspar 10 parts, 5 parts of wollastonite, 5 parts of sandstone, 2 parts of sodium oxide; the bottom glaze includes the following raw materials in parts by weight: 14 parts of halloysite, 11 parts of china clay, 10 parts of pearlite, 10 parts of brucite, 7 parts of talcum powder parts, 6 parts of alumina; the color glaze raw materials include mica powder, dickite powder, and colorant in a weight ratio of 2:1:4, and the colorant is iron, manganese, nickel, copper, tin, magnesium, cobalt At least one of elemental substance or oxide.

[0038]A method for manufacturing emerald glaze craft ceramics, comprising the following steps:

[0039] Step 1, take each raw material respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com