Preparation method of enteromorpha prolifera active carbon composite manganese dioxide supercapacitor electrode material

A supercapacitor, manganese dioxide technology, used in hybrid capacitor electrodes, nanotechnology for materials and surface science, nanotechnology, etc. The effect of high product quality and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) the salvaged Enteromorpha is dried and cleaned;

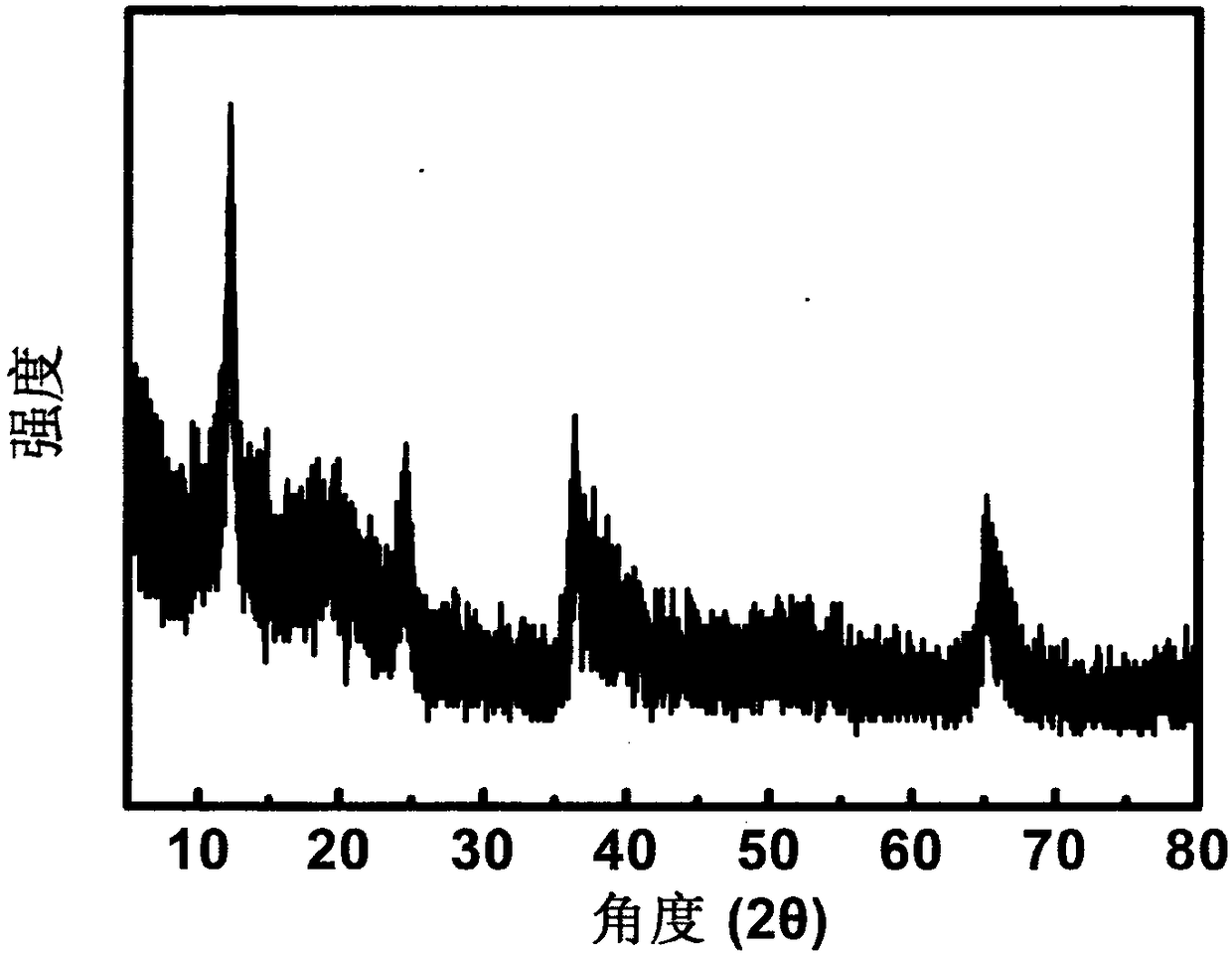

[0025] (2) The Enteromorpha processed in step 1 is roasted at a high temperature at 700° C. under a nitrogen atmosphere in a tube furnace, and carbonized to obtain carbonized Enteromorpha;

[0026] (3) The carbonized Enteromorpha enteromorpha and potassium hydroxide in step 2 are uniformly mixed in a mass ratio of 1:4, and roasted at a high temperature of 800° C. in nitrogen in a tube furnace for activation. The product is fully washed, suction filtered, dried, and collected to obtain Enteromorpha activated carbon;

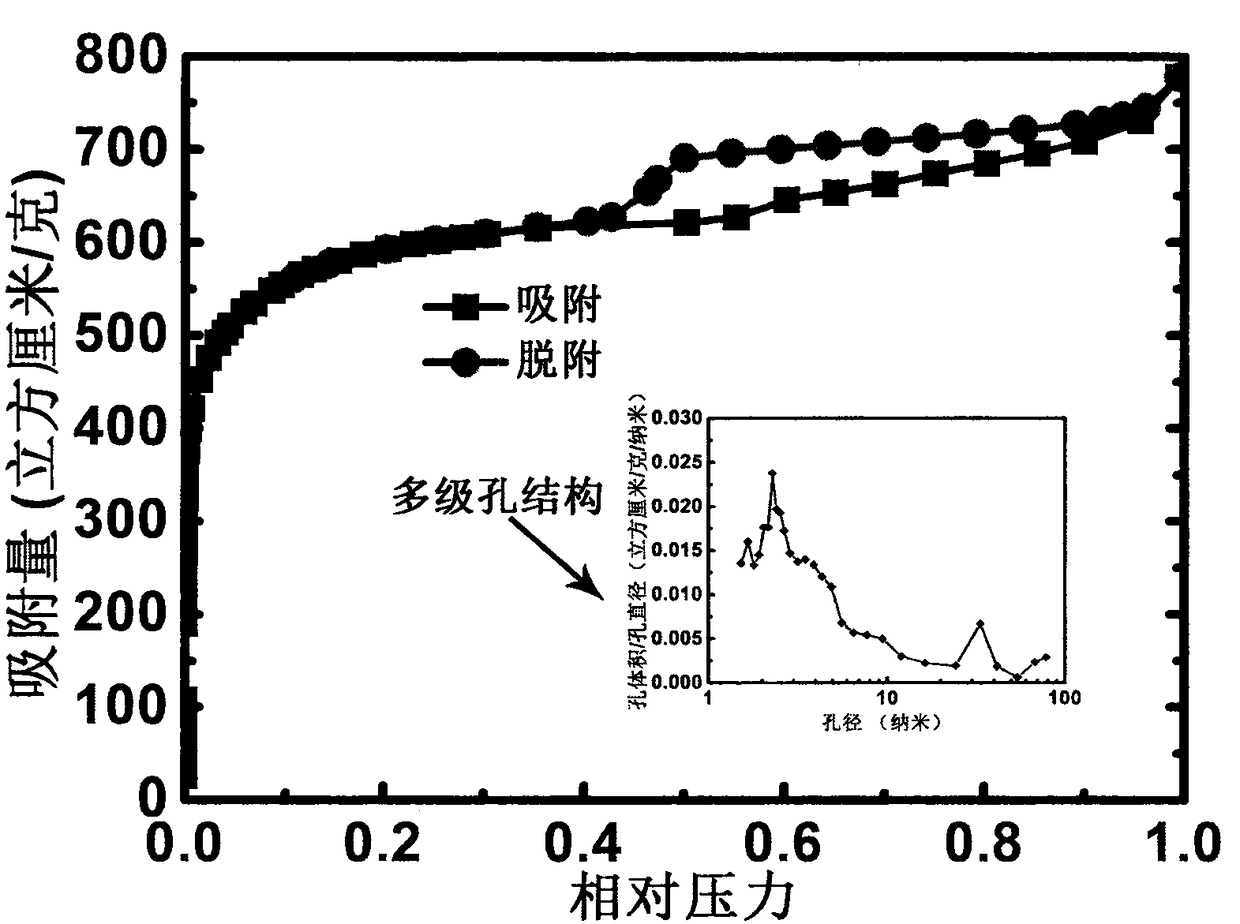

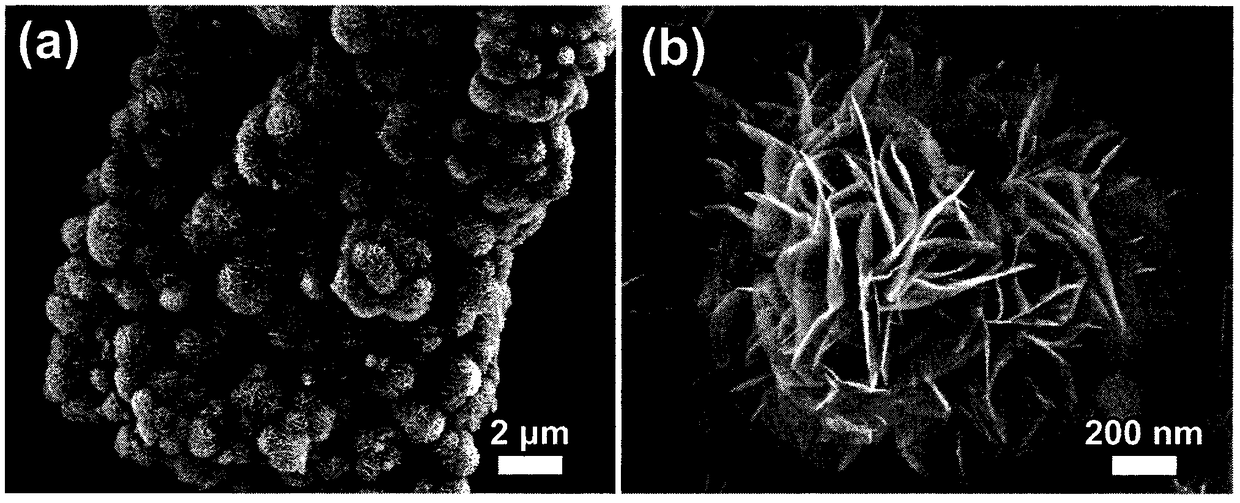

[0027] (4) Get step 3 and get the obtained Enteromorpha activated carbon 0.024g ultrasonic dispersion and carry out chemical damp-heat reaction at 80 ℃ in oil bath with potassium permanganate of 0.316g and 0.25 ml of concentrated sulfuric acid, and the reaction time is 1h;

[0028] (5) Suction filter the mixed solution after the reaction, wash the sediment several times, dry and collect to obtain the en...

Embodiment 2

[0031] (1) the salvaged Enteromorpha is dried and cleaned;

[0032] (2) The Enteromorpha processed in step 1 is roasted at a high temperature at 700° C. under a nitrogen atmosphere in a tube furnace, and carbonized to obtain carbonized Enteromorpha;

[0033] (3) The carbonized Enteromorpha enteromorpha and potassium hydroxide in step 2 are uniformly mixed in a mass ratio of 1:4, and roasted at a high temperature of 800° C. in nitrogen in a tube furnace for activation. The product is fully washed, suction filtered, dried, and collected to obtain Enteromorpha activated carbon;

[0034] (4) Get step 3 and get the obtained Enteromorpha activated carbon 0.024g ultrasonic dispersion to carry out chemical damp-heat reaction at 80 ℃ in oil bath with potassium permanganate of 0.316g and 0.25 ml of concentrated sulfuric acid, and the reaction time is 3h;

[0035] (5) Suction filter the mixed solution after the reaction, wash the sediment several times, dry and collect to obtain the ent...

Embodiment 3

[0038] (1) the salvaged Enteromorpha is dried and cleaned;

[0039] (2) The Enteromorpha processed in step 1 is roasted at a high temperature at 700° C. under a nitrogen atmosphere in a tube furnace, and carbonized to obtain carbonized Enteromorpha;

[0040] (3) The carbonized Enteromorpha enteromorpha and potassium hydroxide in step 2 are uniformly mixed in a mass ratio of 1:4, and roasted at a high temperature of 800° C. in nitrogen in a tube furnace for activation. The product is fully washed, suction filtered, dried, and collected to obtain Enteromorpha activated carbon;

[0041] (4) Get step 3 and get the obtained Enteromorpha activated carbon 0.024g ultrasonic dispersion to carry out chemical damp-heat reaction with 0.316g of potassium permanganate and 0.25 ml of concentrated sulfuric acid in an oil bath at 80°C, and the reaction time is 6h;

[0042] (5) Suction filter the mixed solution after the reaction, wash the sediment several times, dry and collect to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com