A kind of supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., to avoid harm to the human body and the environment, low AC impedance, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

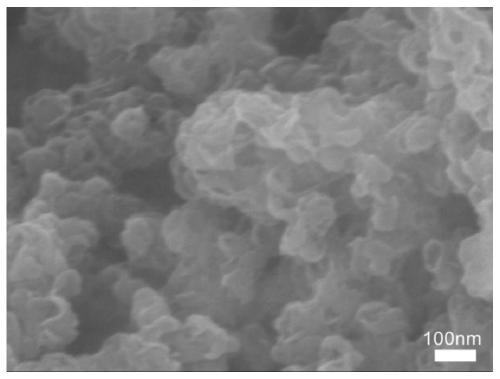

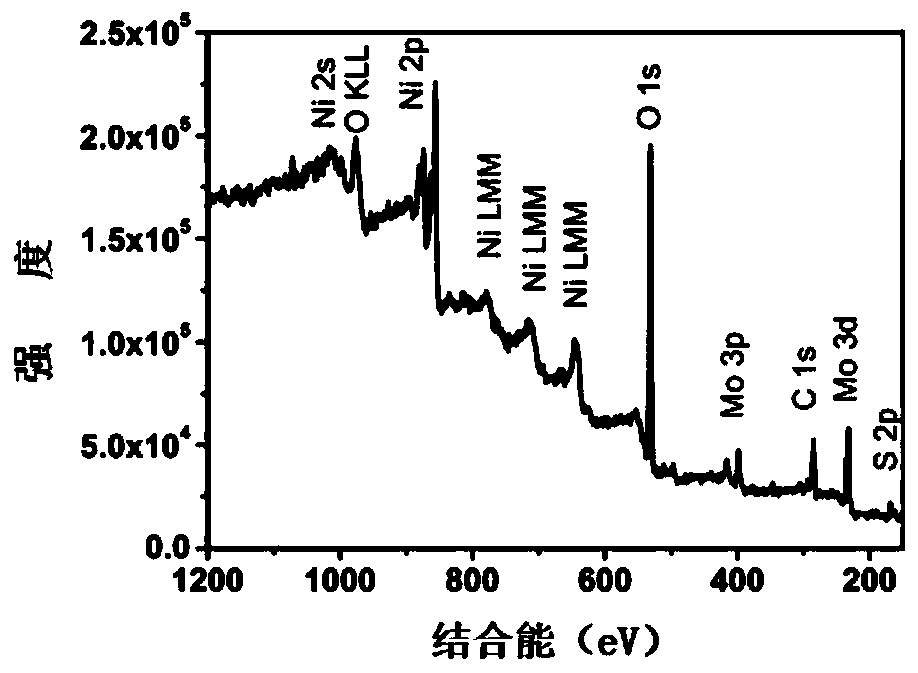

[0038] S1, NiMoS-Ni 3 S 2 Synthesis of Composite Nanosheets:

[0039] S11. Cut the nickel foam into a rectangle, put it into a beaker with 100mL of absolute ethanol, clean it ultrasonically for 10min, then put it into a beaker with 100mL of deionized water, clean it twice again with ultrasonic wave, and finally place it in an oven at 80°C. Dry in medium for 2h, promptly obtain the foamed nickel sheet that the surface has been cleaned, and set aside;

[0040] S12. Dissolve 0.25mMol sodium molybdate and 2mMol thioacetamide powder in deionized water, stir magnetically until the solution is uniformly mixed, then add 0.125mMol oxalic acid powder, stir until the solution is clear and transparent, then transfer the clear and transparent solution to poly In the tetrafluoroethylene liner, put the foamed nickel sheets cleaned in step S1 at the same time, and then react in a blast drying oven at 200°C for 10h after sealing with an autoclave (during this process, the formed NiMoS nanosh...

Embodiment 2

[0043] S1, NiMoS-Ni 3 S 2 Synthesis of Composite Nanosheets:

[0044] S11. Cut the nickel foam into a rectangle, put it into a beaker with 100mL of absolute ethanol, ultrasonically clean it for 10min, then put it into a beaker with 100mL of deionized water, and ultrasonically clean it again for 3 times, and finally place it in an oven at 80°C. Dry in medium for 2h, promptly obtain the foamed nickel sheet that the surface has been cleaned, and set aside;

[0045] S12. Dissolve 0.5mMol sodium molybdate and 2mMol thioacetamide powder in deionized water, stir magnetically until the solution is uniformly mixed, then add 0.125mMol oxalic acid powder, stir until the solution is clear and transparent, then transfer the clear and transparent solution to poly In the tetrafluoroethylene liner, put the foamed nickel sheets cleaned in step S1 at the same time, and then react in a blast drying oven at 200°C for 10h after sealing with an autoclave (during this process, the formed NiMoS nan...

Embodiment 3

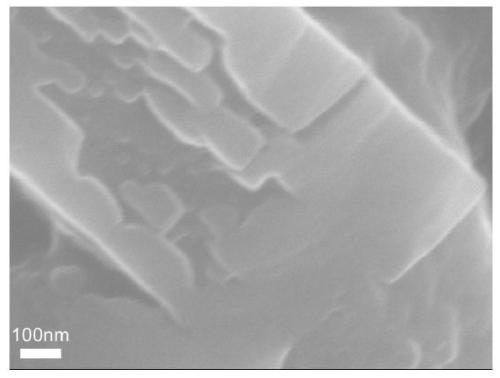

[0048] S1, NiMoS-Ni 3 S 2 Synthesis of Composite Nanosheets:

[0049] S11. Cut the nickel foam into a rectangle, put it into a beaker with 100mL of absolute ethanol, ultrasonically clean it for 10min, then put it into a beaker with 100mL of deionized water, and ultrasonically clean it again for 3 times, and finally place it in an oven at 80°C. Dry in medium for 2h, promptly obtain the foamed nickel sheet that the surface has been cleaned, and set aside;

[0050] S12. Dissolve 0.75mMol sodium molybdate and 2mMol thioacetamide powder in deionized water, stir magnetically until the solution is uniformly mixed, then add 0.125mMol oxalic acid powder, stir until the solution is clear and transparent, then transfer the clear and transparent solution to poly In the tetrafluoroethylene liner, put the foamed nickel sheets cleaned in step S1 at the same time, and then react in a blast drying oven at 200°C for 10h after sealing with an autoclave (during this process, the formed NiMoS na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com