Method for surface vulcanization of spinel nickel lithium manganese oxide positive electrode material

A positive electrode material, lithium nickel manganese oxide technology, applied in the field of lithium ion battery material preparation, can solve the problem of weak adhesion between the surface modification layer and the surface of the positive electrode material, the improvement of the electrochemical performance of the positive electrode material, and the increase of the interface of the positive electrode material Resistance and other issues, to achieve the effect of improving cycle performance and rate performance, low cost, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take by weighing 2.724 gram of nickel acetate, 7.348 gram of manganese acetate and 2.300 gram of lithium acetate are dissolved in 400ml deionized water, add 13.142 gram of tartaric acid after continuous stirring at room temperature for 30 minutes, drip ammoniacal liquor in stirring state, adjust the pH value of solution, the solution The pH value is controlled at about 6.8, and then continuously stirred under a water bath at 90°C until a gel-like liquid is obtained.

[0028] The gel liquid was dried for 10 hours in a blast drying oven at a temperature of 280°C, and then the fluffy material obtained after drying was ground to obtain the gel precursor powder.

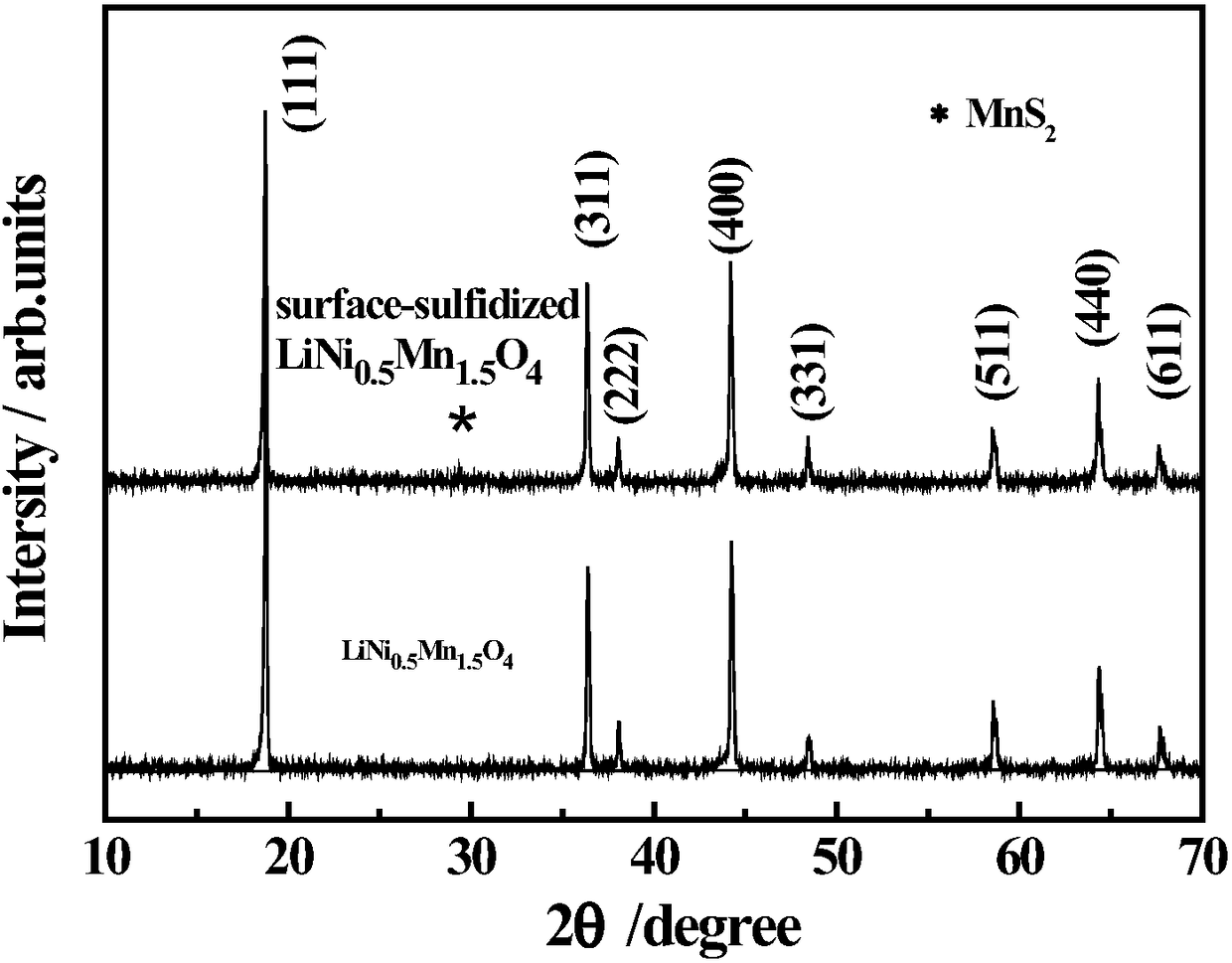

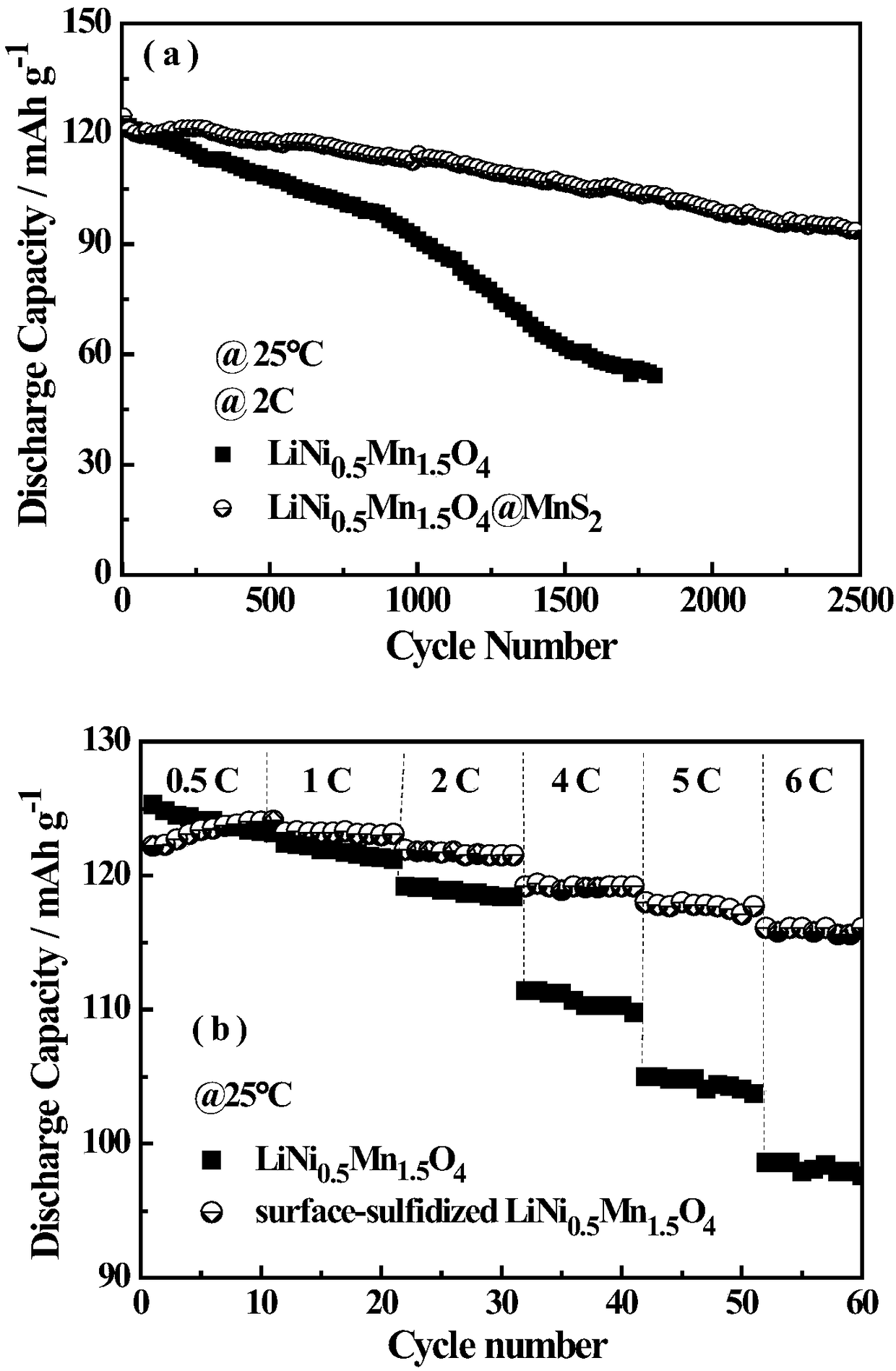

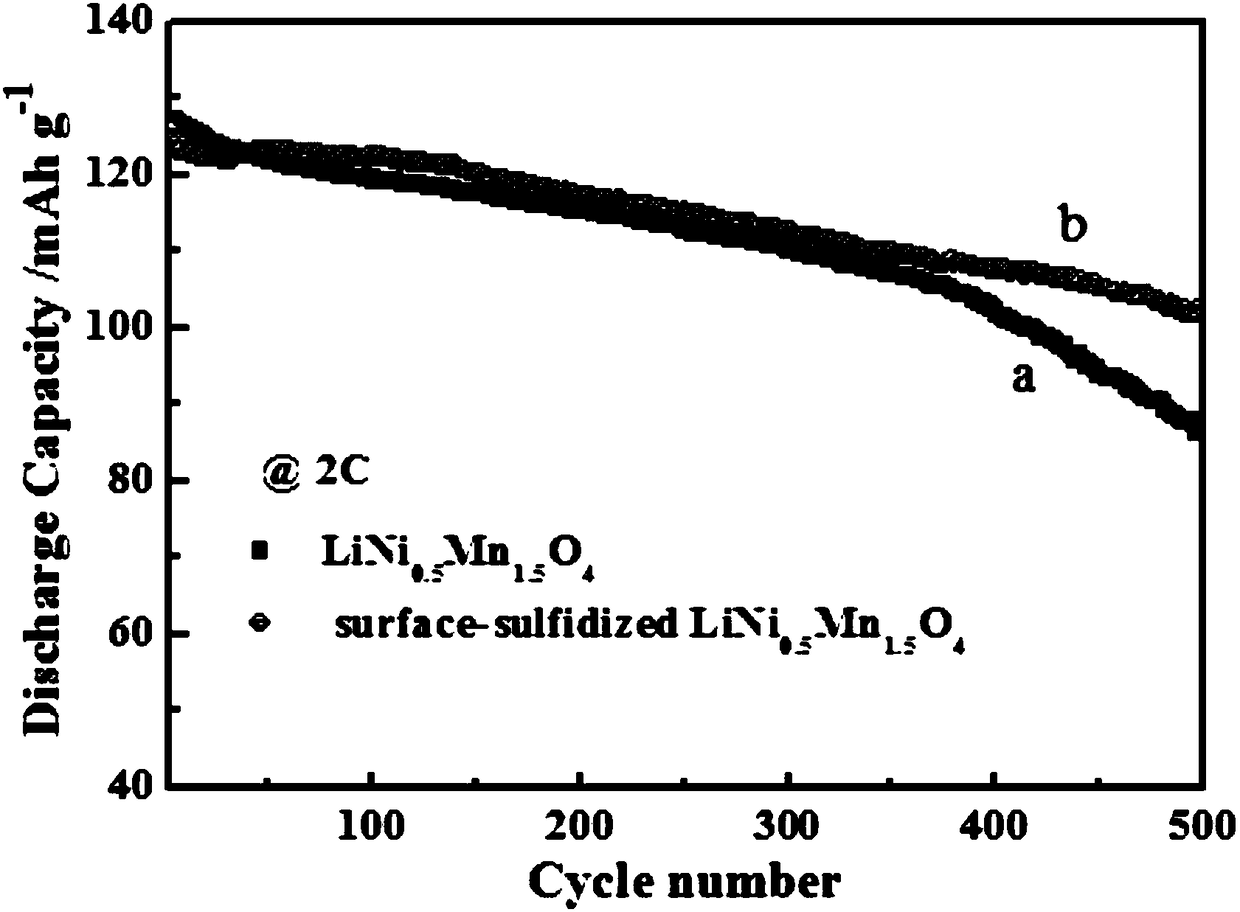

[0029]The collected gel precursor powder was placed in a muffle furnace and calcined in an air atmosphere: firstly, the temperature was raised from room temperature to 500°C at a rate of 3°C / s, and then sintered at 500°C for 5 hours, and then sintered at 3°C / s. The heating rate of °C / min was increased to 900 °C, an...

Embodiment 2

[0039] Weigh 2.918 grams of nickel nitrate, 7.364 grams of manganese acetate and 1.421 grams of lithium nitrate and dissolve them in 400ml of deionized water. After stirring continuously at room temperature for 30 minutes, add and weigh 12.621 grams of citric acid, and drop ethylenediamine into the stirring state to adjust the concentration of the solution. pH value, the pH value of the solution is controlled at about 6.8, and then kept stirring in a water bath at 85°C until a gel-like liquid is obtained. The gel liquid was dried for 16 hours in a forced air drying oven at a temperature of 260°C, and then the fluffy material obtained after drying was ground to obtain the gel precursor powder. The collected gel precursor powder was placed in a muffle furnace and calcined in an air atmosphere: first, the temperature was raised from room temperature to 550 °C at a rate of 3 °C / s, and then sintered at 550 °C for 5 hours, and then sintered at 3 The heating rate of °C / min was increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com