Altrenogest slow-release microsphere and preparation method thereof

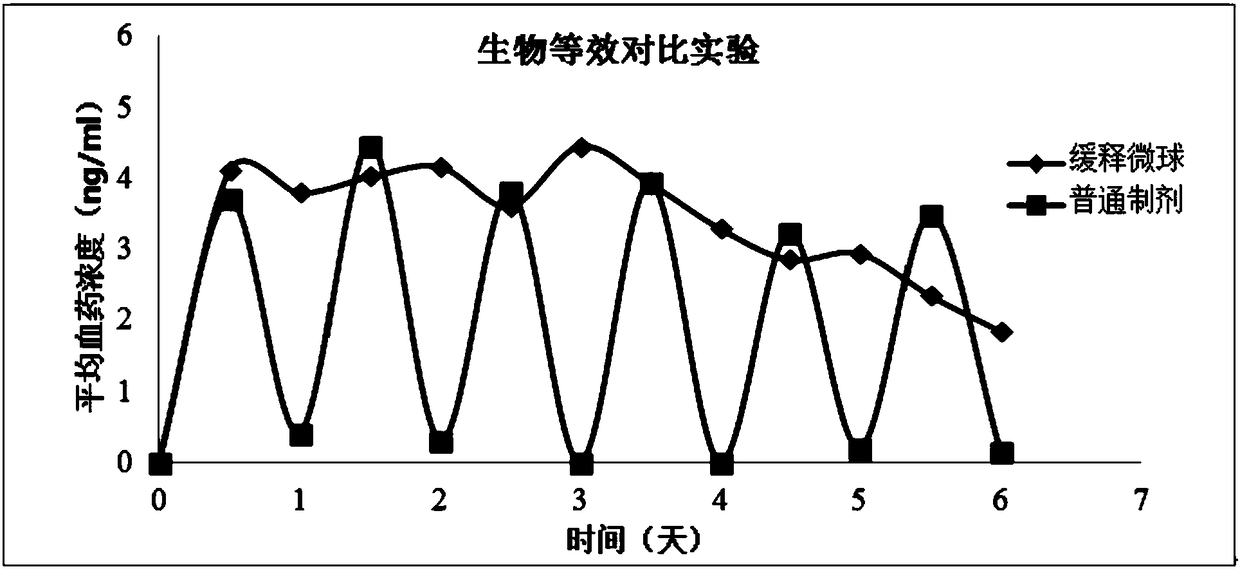

A technology of allylorgestrel and slow-release microspheres, which is applied in the directions of pharmaceutical formulations, microcapsules, medical preparations of inactive ingredients, etc. The first-pass effect of drug effect time and other problems can reduce adverse reactions, reduce the number of administrations, and reduce toxic and side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for allylgestrol sustained-release microspheres, the steps are as follows:

[0035] Weigh 0.12g of allylprogesterone, 0.96g of polymer material, add 8ml of dichloromethane, and ultrasonically dissolve it as the oil phase; take 0.25g of stevioside, 1.0g of gelatin, add 50ml of 0.2% Tween 80 solution, and ultrasonically dissolve, As the water phase; slowly add the oil phase to a certain proportion of the water phase under stirring conditions to form an O / W emulsion; add the O / W emulsion to the remaining water phase under stirring conditions, and stir at room temperature until organic The solvent was completely evaporated, extracted and filtered, washed with purified water for 3 times, and freeze-dried to obtain allylgestrin microspheres.

experiment example 1

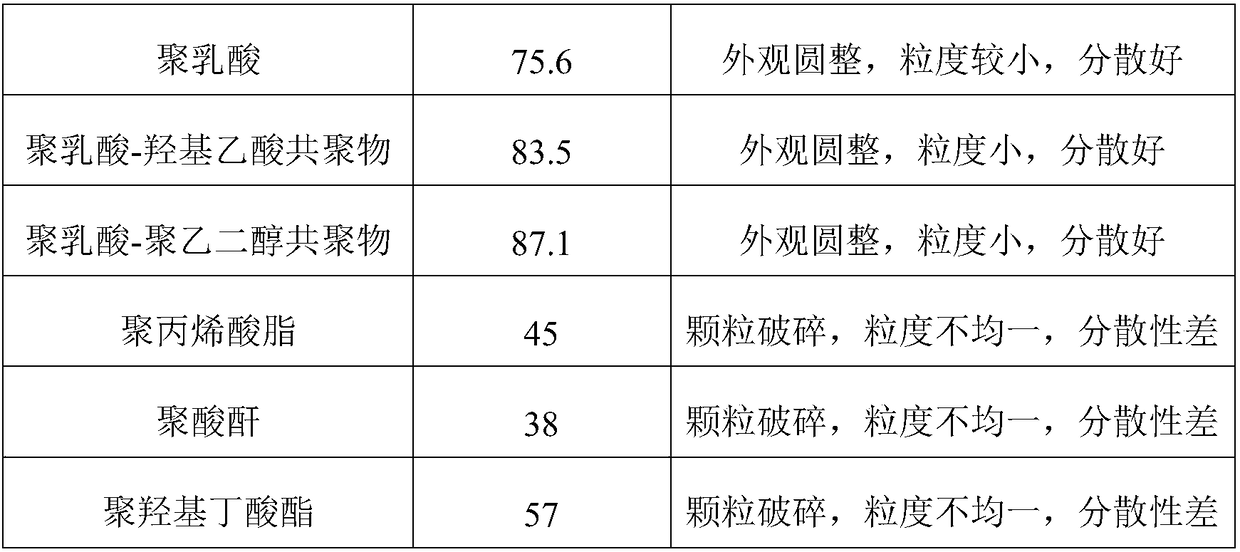

[0037] Change different polymer materials, and conduct quality research and evaluation of allylgestrol microspheres prepared by different polymer materials

[0038] Table 1 Effect of different polymer materials on allylgestrol microspheres

[0039]

[0040]

[0041] It can be seen from the data in Table 1 that polycarbonate, polyamino acid, polylactic acid, polylactic acid-glycolic acid copolymer (PLGA) or polylactic acid-polyethylene glycol copolymer (PLA-PEG) are polymer materials, and The encapsulation rate of allylgestrin microspheres is more than 75%, the appearance is round, the particle size is large, and the dispersion is good; while other materials: polyacrylic resin, polyanhydride, polyhydroxybutyrate encapsulation rate are far less than the present invention , the particles are broken, the particle size is not uniform, and the dispersion is poor.

Embodiment 2

[0043] Dissolve allylprogesterone and PLA-PEG in 8ml of dichloromethane according to the prescription in Table 2, as the oil phase; take 0.25g of stevioside, 1.0g of gelatin, add 50ml of 0.2% different surfactant solutions, ultrasonically dissolve, and use as water phase; slowly add the oil phase to a certain proportion of the water phase under stirring conditions to form an O / W emulsion; add the O / W emulsion to the remaining water phase under stirring conditions, and stir at room temperature until the organic solvent volatilizes Completely, extract and filter, wash with purified water three times, freeze-dry to prepare allylgestrin microspheres.

[0044] Table 2 Composition of different surfactant formulations of allylgestrin microcapsules

[0045]

[0046]

[0047] The allylgestrin microsphere prepared by embodiment 2 is carried out quality research evaluation

[0048] The influence of table 3 different surfactants on allylgestrol microspheres

[0049] Surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com