Separation and purification device and method for one-dimensional nano material

A technology of nanomaterials and purification methods, applied in the field of one-dimensional nanomaterial separation and purification devices, can solve problems such as health damage to operators, low separation efficiency, and decreased production efficiency, and achieve improved separation and purification efficiency, uniform size distribution, and improved morphology. single effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The existing 1L nano silver wire reaction solution with a concentration of 50 mg / mL contains a large number of nano silver particles with a particle size of about 500 nm. The goal is to remove the nano silver particles to obtain nano silver wires with a length of about 30 μm and a diameter of about 25 nm.

[0043] A one-dimensional nanomaterial separation and purification method, including the following steps:

[0044] 1) Preparation of the stock solution: Add deionized water to the nano silver wire reaction solution to dilute to a concentration of 20mg / mL, and then add polyvinylpyrrolidone with a molecular weight of 50,000 until the mass percentage of the polyvinylpyrrolidone in the stock solution is 0.1%;

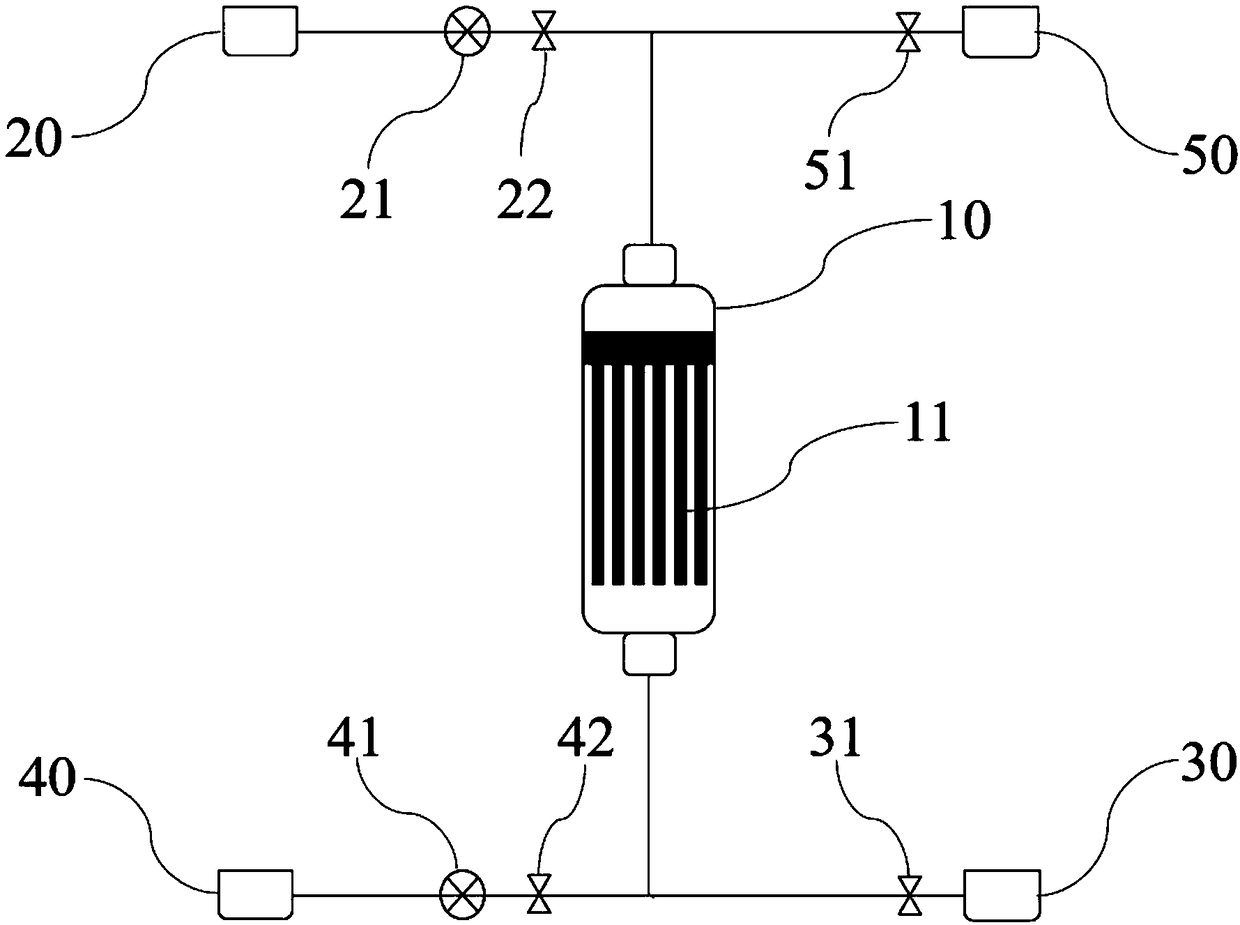

[0045] 2) Installation of separation and purification equipment: according to figure 1 Set up a separation and purification device, the length of the tubular membrane filter tube is 1m, the number is 8, the pore size of the filter hole is 2 ~ 3μm, and the material is PTFE;...

Embodiment 2

[0049] The existing 2L carbon nanotube reaction solution, with a concentration of 20mg / mL, contains carbon nanotubes with different aspect ratios. The length ranges from 1 to 20 μm and the diameter ranges from 1 to 300 nm. The goal is to remove the thicker and shorter carbon nanotubes. Tube to obtain carbon nanotubes with a length of 10-20 μm and a diameter of 1-20 nm.

[0050] A one-dimensional nanomaterial separation and purification method, including the following steps:

[0051] 1) Preparation of the stock solution: Add deionized water to the carbon nanotube reaction solution to dilute to a concentration of 10 mg / mL, and then add triethylhexyl phosphoric acid until the mass percentage of triethylhexyl phosphoric acid in the stock solution is 0.5%;

[0052] 2) Installation of separation and purification equipment: according to figure 1 Set up a separation and purification device, the length of the tubular membrane filter tube is 2m, the number is 6, the pore size of the filter hol...

Embodiment 3

[0055] The existing 2L nano-copper wire reaction solution with a concentration of 100mg / mL contains a large amount of nano-copper particles and nano-copper rods. The particle size is about 300nm, and the average diameter of the copper rods is about 300nm. The goal is to remove nano-copper particles and nano-copper rods. , To obtain a copper nanowire with a length of about 50μm and a diameter of about 100nm.

[0056] A one-dimensional nanomaterial separation and purification method, including the following steps:

[0057] 1) Preparation of the original solution: Add deionized water to the nano copper wire reaction solution to dilute to a concentration of 30 mg / mL, and then add polyacrylamide with a molecular weight of 10,000 until the mass percentage of polyacrylamide in the original solution is 0.2%;

[0058] 2) Installation of separation and purification equipment: according to figure 1 Set up a separation and purification device, the length of the tubular membrane filter tube is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filter pore size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com