Rod-like g-C3N4@SnIn4S8 composite photocatalyst and method for preparing same

A g-c3n4, composite light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of long time, high synthesis temperature, fast electron and hole recombination, etc. The effect of reducing the recombination rate and easier separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The chemical reagents used in the present invention are all analytically pure, purchased from Aladdin Reagent Company, and the experimental water is deionized water. Specific steps are as follows:

[0033] (1) Preparation of pure g-C 3 N 4 : Weigh 30 g of urea and place it in a crucible, dry it in an oven at 80°C for 8 h, and stir once every 1 h to ensure that the urea is fully dried. Place in a muffle furnace, raise the temperature to 550°C at a rate of 10°C / min, and keep the temperature constant for 2 h. Cool to room temperature and grind to obtain a pale yellow solid (pure g-C 3 N 4 ).

[0034] (2) Preparation of g-C 3 N 4 @SnIn 4 S 8 Composite photocatalyst: 0.5559 g of g-C 3 N 4 powder (molecular weight: 92, 6.042 mmol) and 0.07012 g SnCl 4 • 5H 2 O (molecular weight: 350.60, 0.2 mmol) was dissolved in 80 mL of deionized water, and after sonication for 40 min, 0.2407 g of In(NO 3 ) 3 • 5H 2 O (molecular weight: 300.83, 0.8 mmol), 0.2341 g of C 2 H ...

Embodiment 2

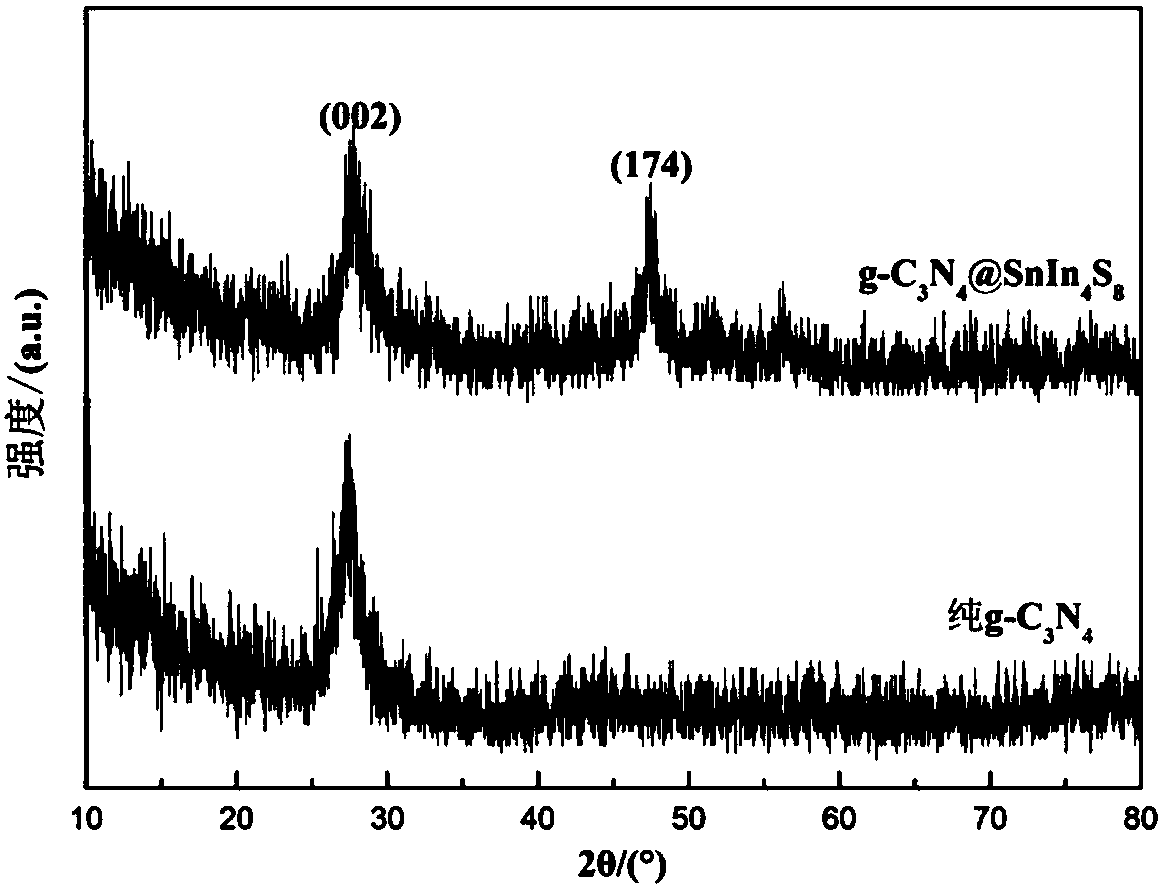

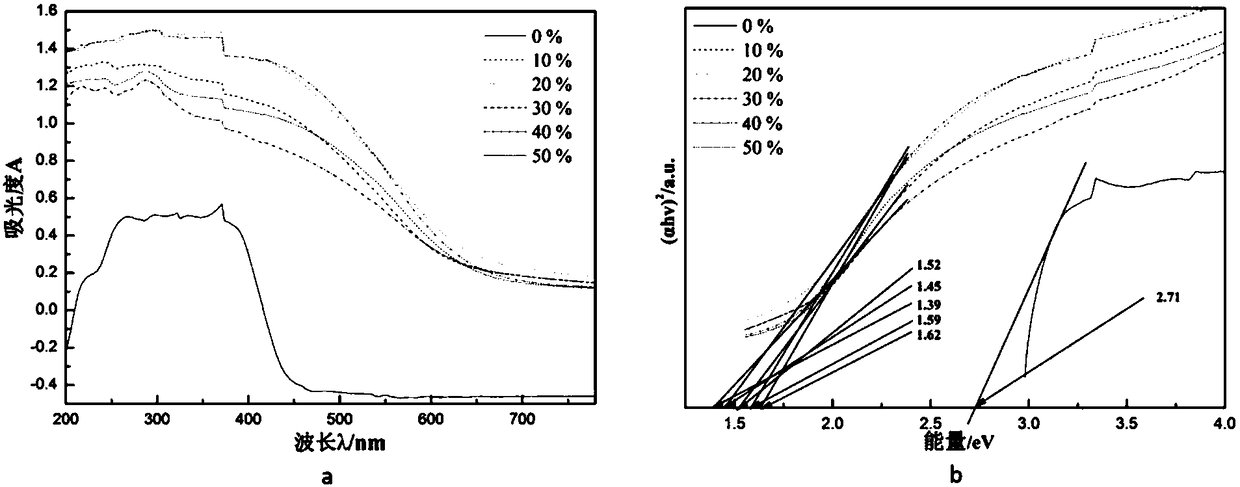

[0037] The preparation method of embodiment 2 is identical with embodiment 1, just pure g-C 3 N 4 with SnIn 4 S 8 The mass ratio is set to different loading gradients, and photocatalysts with different loading ratios are prepared, which are changed to 10%, 20%, 40%, and 50% g-C 3 N 4 @SnIn 4 S 8 composite photocatalyst. X-ray diffraction pattern (XRD) as Image 6 As shown, g-C appeared in the composite sample 3 N 4 and SnIn 4 S 8 characteristic peaks, indicating that g-C 3 N 4 with SnIn 4 S 8 compounded successfully. At the same time, the corresponding g-C after compounding 3 N 4 The intensity of the diffraction peak (002) crystal plane decreases with the increase of the loading ratio, which is mainly due to the fact that the SnIn 4 S 8 The addition of SnIn makes the 4 S 8 Crystals covered in g-C 3 N 4 surface, inhibiting the g-C 3 N 4 growth, making g-C 3 N 4 The intensity of the diffraction peaks was significantly reduced. Compared Figure 4 It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com