Kitchen waste recovery treatment technology

A technology for recycling and processing food waste, which is applied in the field of resource recycling and recycling, can solve problems such as health hazards, and achieve the effects of activating potential nutrients, good environmental benefits, and increasing soil organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

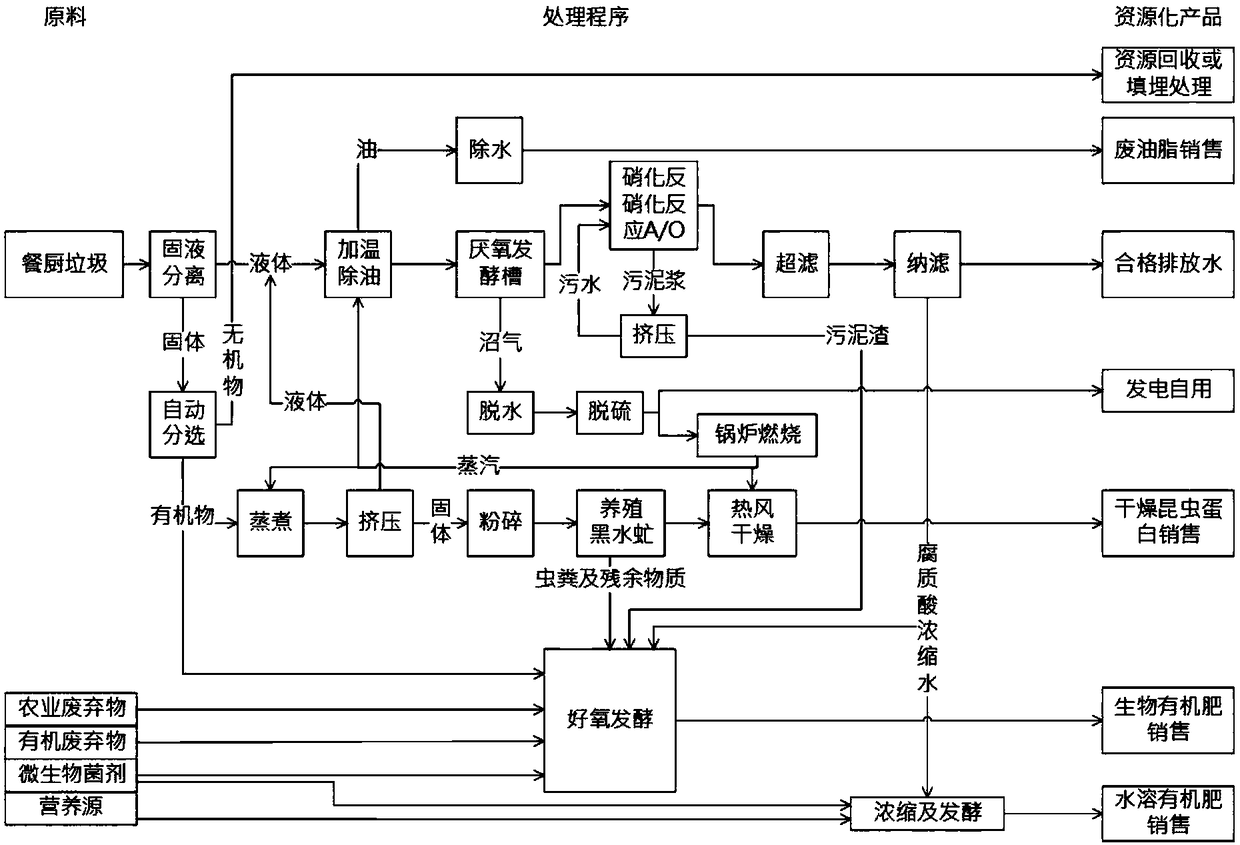

[0041] refer to figure 1 As shown, the present invention is a kind of food waste recycling process, comprising the following steps;

[0042] Step 1. Solid-liquid separation: take the kitchen waste, and use a solid-liquid separation device to separate the food waste into solid-liquid phase to obtain solid-phase kitchen waste and liquid-phase kitchen waste;

[0043] Step 2. Solid waste sorting: effectively separate and sort the organic matter and inorganic matter in the solid-phase food waste through the food waste pretreatment equipment;

[0044] Step 3, solid organic waste treatment: steaming, extruding and pulverizing a part of the organic matter sorted in step 2 to obtain organic breeding feed, and using the obtained organic breeding feed for black soldier fly breeding;

[0045] Step 4, liquid waste treatment: combine the kitchen waste in the liquid phase in step 1 and the liquid obtained in the extrusion process in step 3 to obtain a liquid phase material, and use an oil-w...

Embodiment 2

[0065] Wherein, step 5 aerobic fermentation process following steps:

[0066] a. Separately crush organic waste and agricultural waste;

[0067] b. Mix 40kg of organic matter, 20kg of insect excrement and residual substances, 5kg of microbial agent and 15kg of sludge residue in the solid-phase kitchen waste and evenly stack them on the bottom, and then pile up 100kg of crushed organic waste and agricultural waste on the bottom Finally, 150kg of humic acid concentrated water will be added from the top of the pile by spraying;

[0068] c. Since the mixture is put in, within 72 hours, the fermentation temperature reaches 55-60°C and lasts for 3-5 days, then the temperature drops naturally, and the fermentation is completed when it drops to 35-40°C.

[0069] Among them, 50kg of straw, 80kg of weed leaves, and 20kg of fruit shells are used for agricultural waste; waste paper is used for organic waste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com