Preparation method of antibacterial polysaccharide

A polysaccharide and polysaccharide solution technology, applied in the field of antibacterial polysaccharide preparation, to achieve excellent antibacterial performance, convenient operation, and less demanding reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention proposes a method for preparing antibacterial polysaccharides, which uses atmospheric pressure plasma jet discharge to treat polysaccharide solutions to prepare antibacterial polysaccharides. Specifically, the polysaccharide is firstly dissolved in water to prepare a polysaccharide solution, and then the polysaccharide solution is subjected to atmospheric pressure plasma jet discharge treatment by using a plasma device to remove water to obtain an antibacterial polysaccharide.

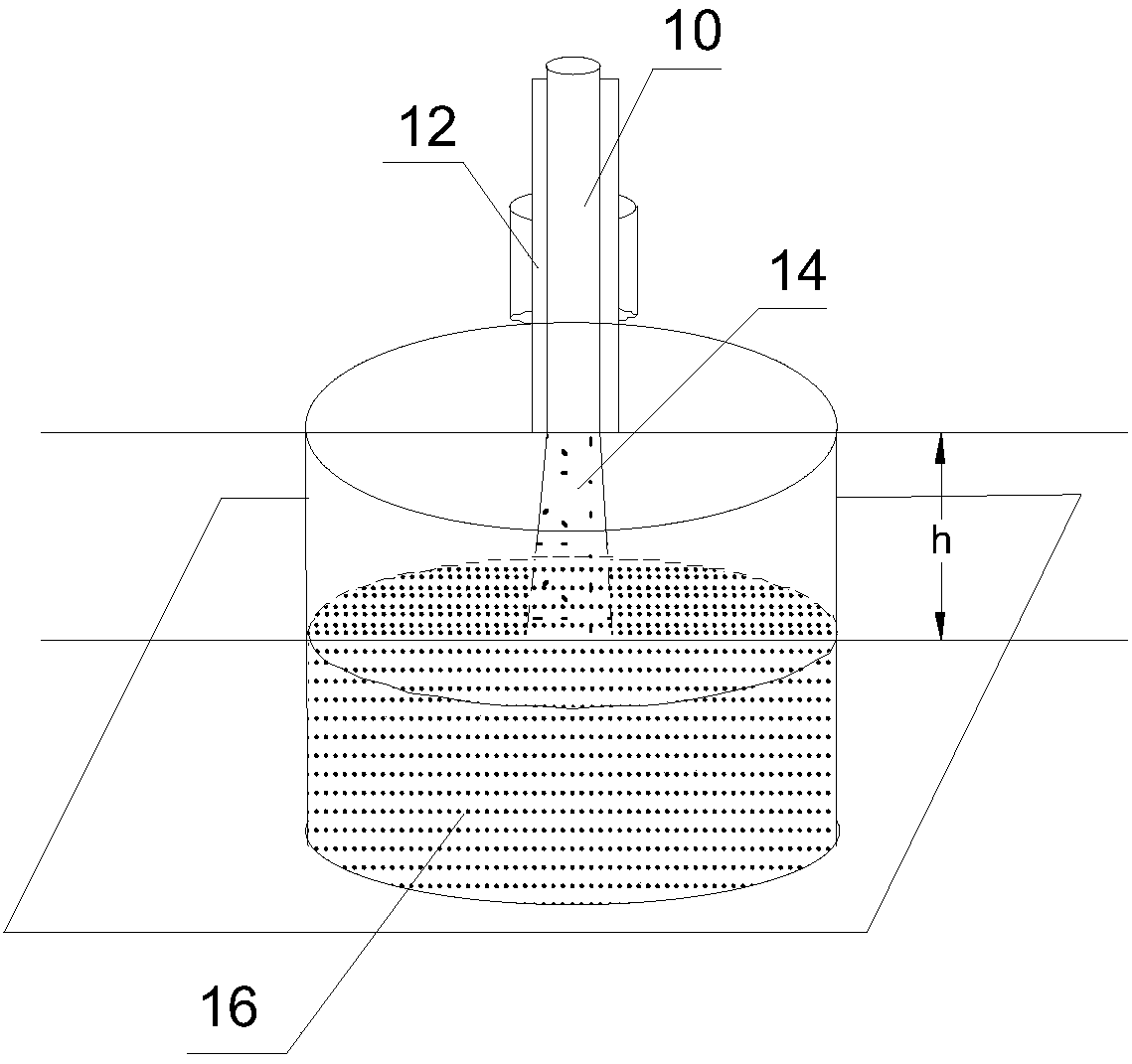

[0022] Among them, the plasma device is mainly composed of a gas passage, a single-needle electrode, a voltage regulator and a processing container. For details, please refer to figure 1 , figure 1 It is a partial structural schematic diagram of the atmospheric pressure plasma jet discharge treatment system device used in the present invention.

[0023] During use, when the gas is compressed and passes through the gas channel 10 through the single needle electrode 12, the high pr...

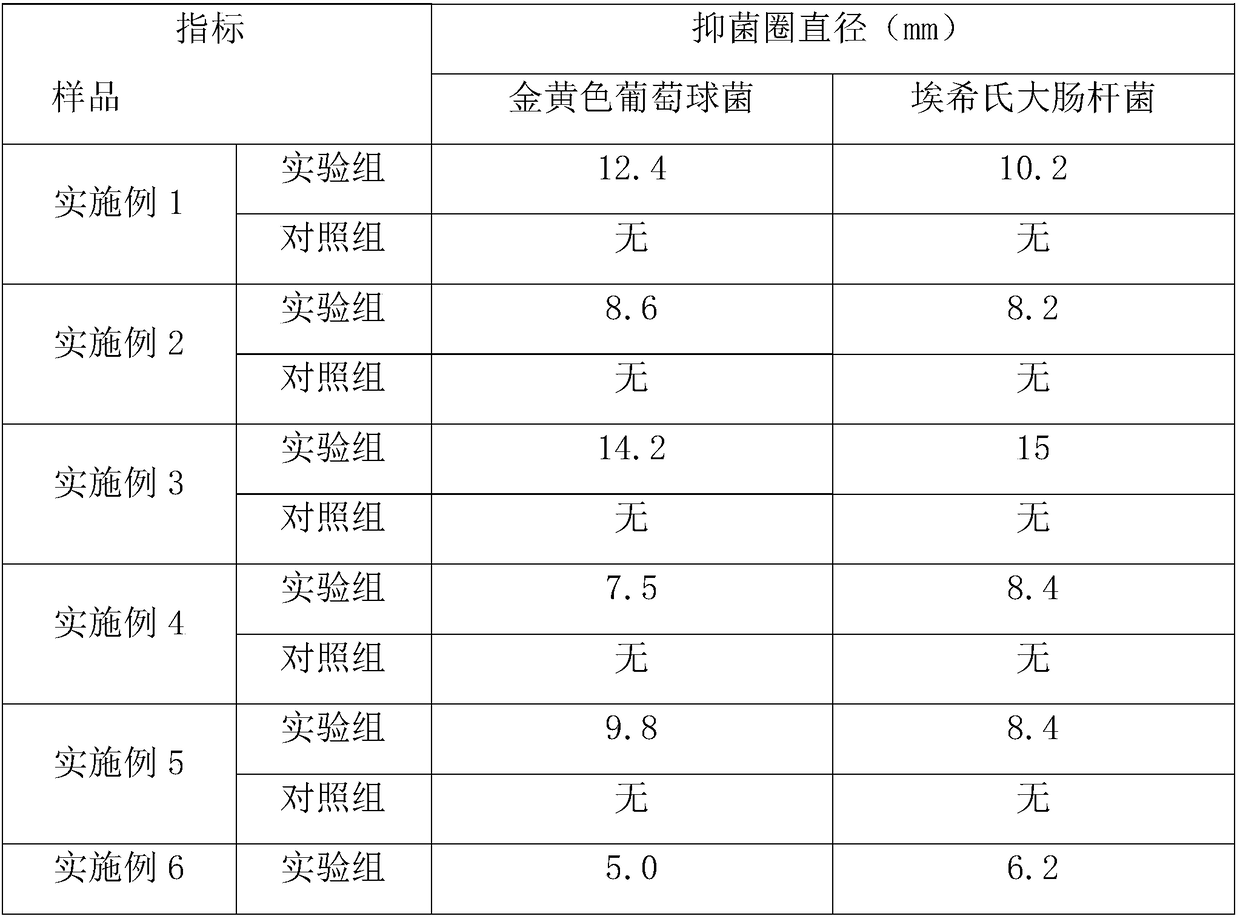

Embodiment 1

[0029] Add 0.5g of sodium alginate powder into 99.5mL of water, heat to 60°C, stir magnetically for 2 hours until completely dissolved, and then let it stand for defoaming to obtain a sodium alginate solution with a mass concentration of 0.5%.

[0030] Take 50mL of sodium alginate solution and place it in the container, and adjust the position of the electrode to be 2-3mm above the liquid surface of the sodium alginate solution. The gas source is oxygen, and the gas valve is adjusted so that the gas flow rate is 30mL / min. The DC power supply is turned on and the voltage is set to 2000V, and the atmospheric pressure plasma jet discharge treatment is carried out for 60min to obtain a plasma-modified antibacterial polysaccharide solution.

Embodiment 2

[0032] Add 0.1 g of sodium carboxymethyl cellulose powder into 99.9 mL of water, heat to 60°C, stir magnetically for 2 hours until completely dissolved, and then let it stand for defoaming to obtain a 0.1% sodium carboxymethyl cellulose solution.

[0033] Take 50mL of sodium carboxymethyl cellulose solution and place it in a container, and adjust the position of the electrode to be 2 to 3 mm above the liquid surface of sodium carboxymethyl cellulose solution. The gas source is argon, the gas valve is adjusted, the flow rate is 10mL / min, the DC power is turned on and the voltage is set to 1000V, and the atmospheric pressure plasma jet discharge treatment is carried out for 20min to obtain a plasma modified antibacterial polysaccharide solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com