Buried pipeline cathodic protection device and method

A cathodic protection and buried pipeline technology, applied in the field of electric power, can solve the problems of cathodic protection potential fluctuations, difficulty in troubleshooting, increasing construction volume and cycle, etc., to maintain stable physical properties, reduce engineering costs, and extend service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

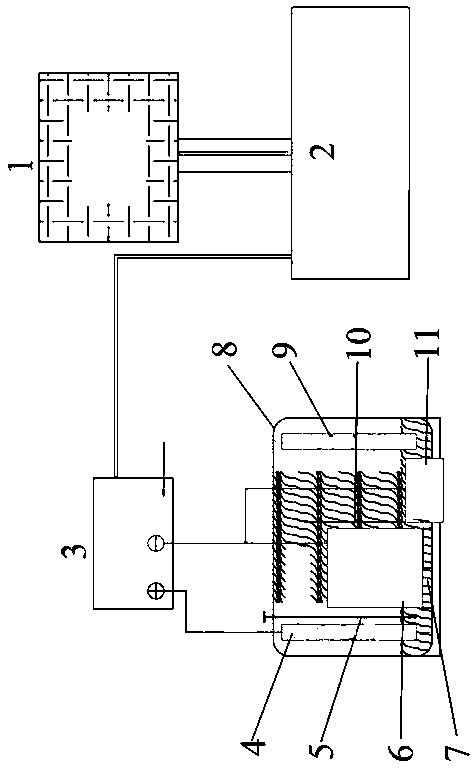

[0080] Embodiment 1: a kind of buried pipeline cathodic protection method and device of embodiment 1, comprises the following steps:

[0081] (1) Impressed current protection system

[0082] a. The power supply of the buried pipeline cathodic combined protection device: the model is WDY-3000s and the power is 3000w. The solar panel is electrically connected to the battery. The battery type is D-lead battery with a capacity of 30AH. It works for 6 hours under sufficient light conditions, and the storage capacity of the battery is 18kw. The solar panel absorbs the power of the sun and transmits it to the battery for storage, which constitutes the power supply of the buried pipeline cathodic joint protection device. The battery terminal is connected to the potentiostat, and the solar panel converts solar energy into electrical energy in the field, stores it in the battery, and provides direct current for the potentiostat, which completely overcomes the technical difficulty of the...

Embodiment 2

[0108] Embodiment 2: In the steps of a kind of buried pipeline cathodic protection method and device of embodiment 2 (1) (2) (4) (5) steps are the same as embodiment 1, wherein step (3) is different, specific steps yes:

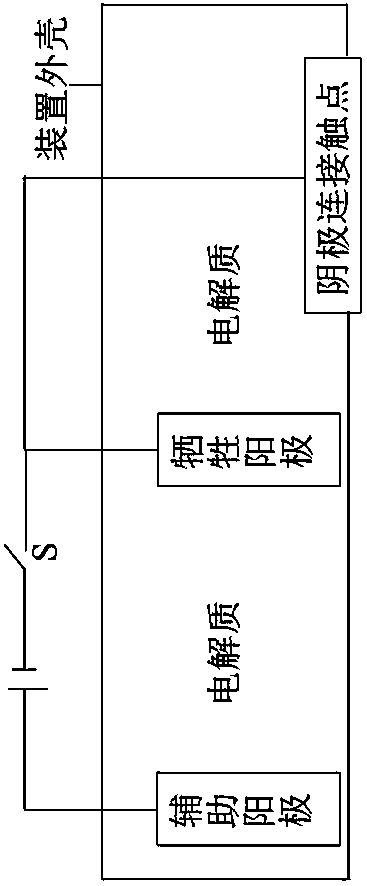

[0109] (3) Preparation of quasi-solid electrolyte

[0110] 30% zinc sulfate solution is added dropwise to 40% sodium hydroxide solution, and mixed in an environment with a water bath temperature of 40° C. to form a flocculent quasi-solid electrolyte. The pH value of the formed quasi-solid electrolyte is 9.2, the resistivity of the prepared electrolyte is 361Ω·cm, and the volatilization rate of the prepared electrolyte is 0.035g·(kg·d) -1 . The electrolyte was subjected to an electrolysis experiment, and it was found that there was metal zinc in the electrolyte after electrolysis. Metal zinc is electrolyzed from the electrolyte, attached to the quasi-solid electrolyte, and exists as tiny particles. In this case, the specific surface area of metal zinc is...

Embodiment 3

[0113] Embodiment 3: (1) (2) (3) (4) (5) a, b steps are the same as embodiment 2 in the step of a kind of buried pipeline cathodic protection method and device of embodiment 3, wherein step (5) )c is different, the specific steps are:

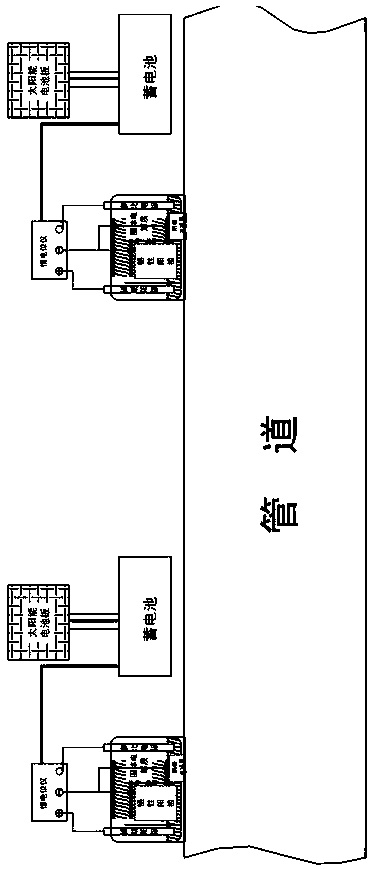

[0114] (5) Construction and operation of buried pipeline cathodic combined protection device

[0115] c. Operation of cathodic combined protection device for buried pipeline

[0116] In order to explore the protective effect of cathodic protection devices on buried pipelines, this experiment simulates buried water pipelines with Q235 carbon steel pipes. Take two sections of Q235 carbon steel pipes, the pipe diameter is 25mm, the pipe length is 500mm, and they are respectively labeled #1 and #2. Take the #2 pipe section as a blank control test, and carry out cathodic protection on the #1 pipe section; in this experiment, the two sections of pipes are connected in series , buried in the soil, the buried depth is 800mm, the soil resistivity is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com