A method for growing crystal cladding in a metal tube

An in-growth, metal tube technology, applied in the directions of cladding fiber, crystal growth, single crystal growth, etc., can solve the problems of easy cracking of cladding, low sol-gel efficiency, low process qualification rate, etc., and achieve uniform refractive index distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. First grow Lu with a diameter of 0.3-1mm and a length of 65-120mm by the micro-drawing method 2 O 3 Crystal fiber

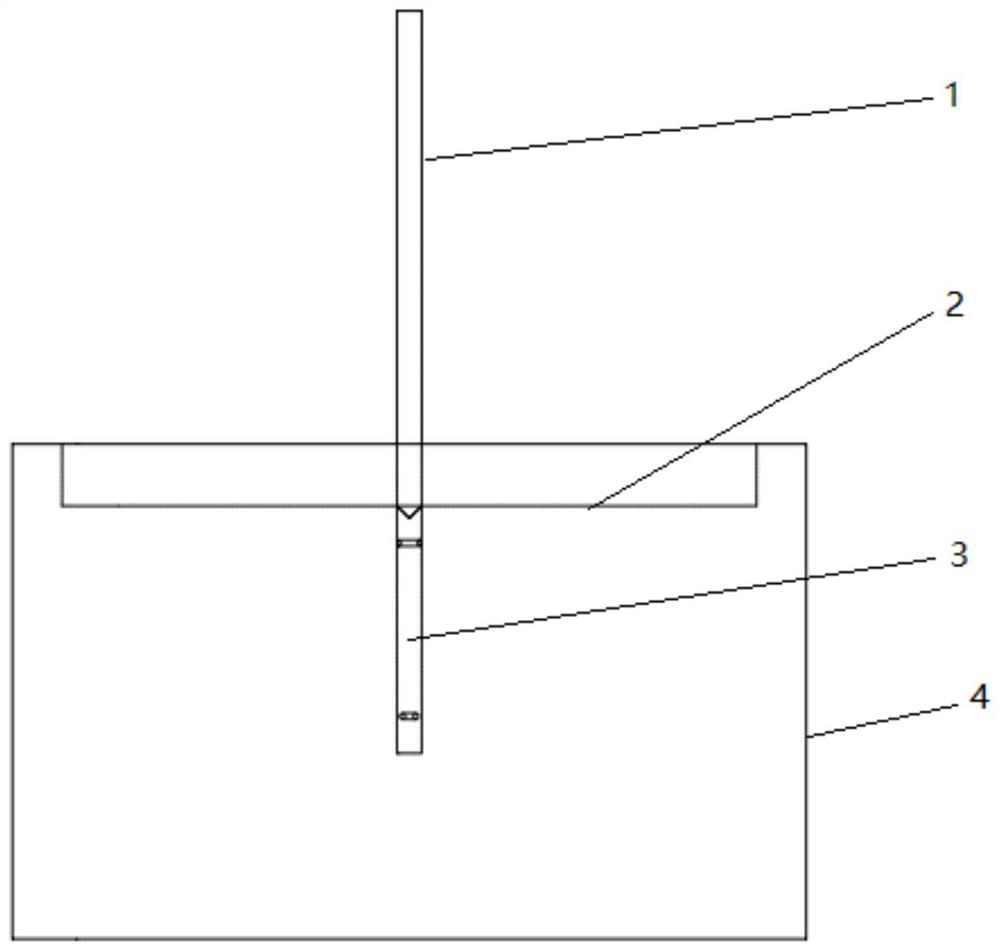

[0024] 2. Insert the optical fiber obtained in the first step into the pre-processed tungsten tube 1 (e.g. figure 1 As shown), the inner diameter of the tungsten tube 1 is slightly larger than the inner diameter of the optical fiber by 0.3-0.8mm. The lower end of the optical fiber is supported by the tungsten wire 3. The lower end 1-2mm of the tungsten tube 1 can be closed to support the tungsten wire 3 and the crystal fiber. Two small holes are made on the side wall 3-5mm above the bottom to ensure that the melt in the crucible can enter the bottom of the metal tube;

[0025] 3. Install the assembled crystal fiber, tungsten tube 1, and tungsten metal wire 3 on the seed rod of the pulling furnace;

[0026] 4. Fill the pulling furnace crucible 4 with LuScO 3 Raw materials, after installing the thermal field, close the furnace door and evacuate to within 10Pa, ...

Embodiment 2

[0029] A method for growing a crystal cladding in a metal tube includes the following steps:

[0030] S01, using micro pull-down or guided mode method, or laser heating pedestal method to obtain a crystal fiber with a diameter of 0.1 mm, wherein the micro pull-down or guided mode method, or laser heating pedestal method are methods disclosed in the existing literature;

[0031] S02, insert the crystal fiber obtained in step S01 into a metal sleeve, the core diameter of the sleeve is greater than the diameter of the fiber by 0.1 mm, the lower end of the sleeve is a metal wire with the same diameter as the crystal fiber, and the length of the metal wire is 20 mm;

[0032] S03, installing the metal sleeve, crystal fiber, and metal wire assembly obtained in step S02 on the seed rod of the crystal growth pulling furnace;

[0033] S04, heating the raw material in the crucible of the pulling furnace to melt, lower the seed rod, so that the metal wire at the lower end of the metal sleeve is pa...

Embodiment 3

[0039] A method for growing a crystal cladding in a metal tube includes the following steps:

[0040] S01: Use the micro pull-down or guided mode method, or the laser heating pedestal method to obtain a crystal fiber with a diameter of 3 mm, wherein the micro pull-down or guided mode method, or the laser heating pedestal method are methods disclosed in the existing literature;

[0041] S02, insert the crystal fiber obtained in step S01 into a metal sleeve, the core diameter of the sleeve is larger than the diameter of the fiber by 0.8 mm, the lower end of the sleeve is a metal wire with the same diameter as the crystal fiber, and the length of the metal wire is 30 mm;

[0042] S03, installing the metal sleeve, crystal fiber, and metal wire assembly obtained in step S02 on the seed rod of the crystal growth pulling furnace;

[0043] S04, heating the raw material in the crucible of the pulling furnace to melt, lower the seed rod, so that the metal wire at the lower end of the metal sleev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com