Nickel magnetic microsphere and preparation method and application thereof

A technology of magnetic microspheres and microspheres, applied in peptide preparation methods, chemical instruments and methods, magnetic materials, etc., can solve problems such as difficult to wash off, long incubation time, slow contact with target proteins, etc., and achieve strong force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

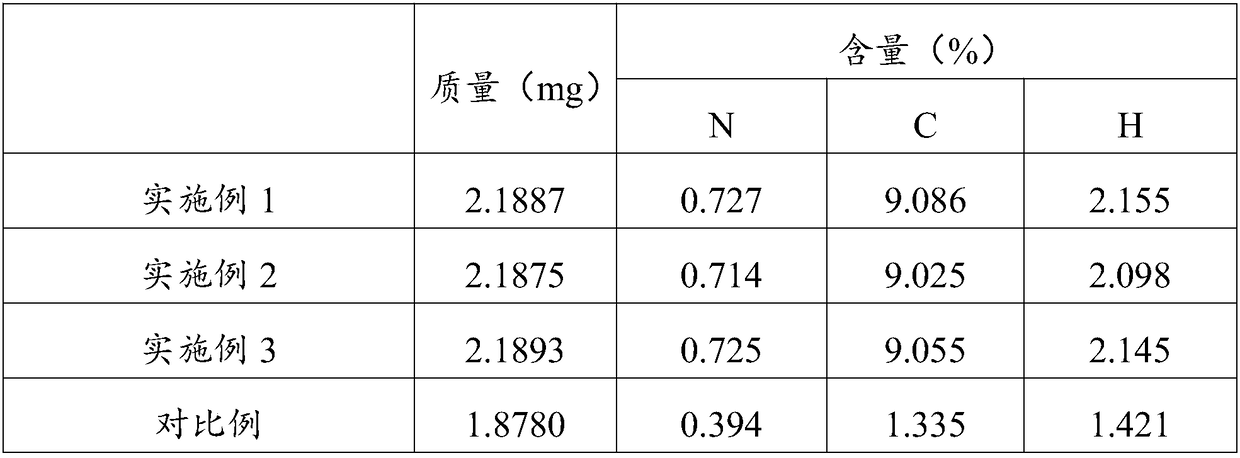

Examples

Embodiment 1

[0026] A kind of nickelized magnetic microsphere, its preparation comprises the steps:

[0027] 1), weigh 1gFe 3 o 4 Particles, add 10mL 0.01mol / L hydrochloric acid solution, activate under ultrasonic conditions for 20min (ultrasonic dispersion power 100W), after magnetic separation, Fe 3 o 4 The particles were washed to neutrality, and then converted to hydrochloric acid-activated Fe 3 o 4 Add 80mL of absolute ethanol, 20mL of ultrapure water, 0.4mL of 25wt% ammonia water and 0.5mL of ethyl orthosilicate to the granules in sequence, react with ultrasound for 2 hours, and wash with ultrapure water until neutral after magnetic separation to obtain magnetic silica microspheres;

[0028] 2) Weigh 1g of the magnetic silica microspheres prepared in step 1), add 80mL of absolute ethanol, 20mL of ultrapure water, 0.4mL of ammonia water and 0.5mL of KH-560 for ultrasonic reaction for 2 hours, and use ultrasonic Washing with pure water to neutrality to obtain epoxidized magnetic s...

Embodiment 2

[0032] 1) Weigh 1g α-Fe 2 o 3 Particles, add 30mL 0.01mol / L hydrochloric acid solution, activate under ultrasonic conditions for 30min (ultrasonic dispersion power 300W), after magnetic separation, Fe 3 o 4 The particles were washed to neutrality, and then converted to hydrochloric acid-activated Fe 3 o 4 Add 130mL of absolute ethanol, 50mL of ultrapure water, 0.7mL of 25wt% ammonia water and 2mL of ethyl orthosilicate to the granules in sequence, react with ultrasound for 2.5h, and wash with ultrapure water until neutral after magnetic separation to obtain magnetic silica microspheres;

[0033] 2) Weigh 1g of the magnetic silica microspheres prepared in step 1), add 130mL of absolute ethanol, 60mL of ultrapure water, 1.1mL of 25wt% ammonia water and 0.9mL of silane coupling agent KH-560 for ultrasonic reaction for 3 hours, After magnetic separation, wash with ultrapure water until neutral to obtain epoxidized magnetic silica microspheres;

[0034] 3), weigh 3g of iminodi...

Embodiment 3

[0037] 1), weigh 1gMgFe 2 o 4Granules, add 40mL 0.01mol / L hydrochloric acid solution, activate under ultrasonic conditions for 40min (ultrasonic dispersion power 500W), after magnetic separation, Fe 3 o 4 Wash the particles until they are neutral, then add 160mL of absolute ethanol, 80mL of ultrapure water, 1.6mL of 25wt% ammonia water and 4mL of tetraethyl orthosilicate to the magnetic substrate activated by hydrochloric acid in sequence, react with ultrasonic for 5h, and use ultrapure water after magnetic separation Washing to neutrality to obtain magnetic silica microspheres;

[0038] 2) Weigh 1g of the magnetic silica microspheres prepared in step 1), add 160mL of absolute ethanol, 80mL of ultrapure water, 1.6mL of 25wt% ammonia water and 4mL of silane coupling agent KH-560 for ultrasonic reaction for 5 hours, magnetic After separation, wash with ultrapure water until neutral to obtain epoxidized magnetic silica microspheres;

[0039] 3) Weigh 4g of iminodiacetic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com