Preparation method of epitaxial wafer for 8-inch high-power IGBT component

A technology for components and epitaxial wafers, which is used in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve the problems of high output efficiency, low efficiency, and increased splintering rate, so as to avoid the increase of splintering rate and improve the Growth rate, the effect of improving electrical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of preparation method of the epitaxial wafer for 8-inch high-power IGBT component of the present invention comprises the following steps:

[0022] A. Preparing the substrate sheet: select an 8-inch substrate sheet doped with phosphorus, with a resistivity of 3-25Ω·cm, and the back-sealing structure is polycrystalline (Poly) back-sealing mode;

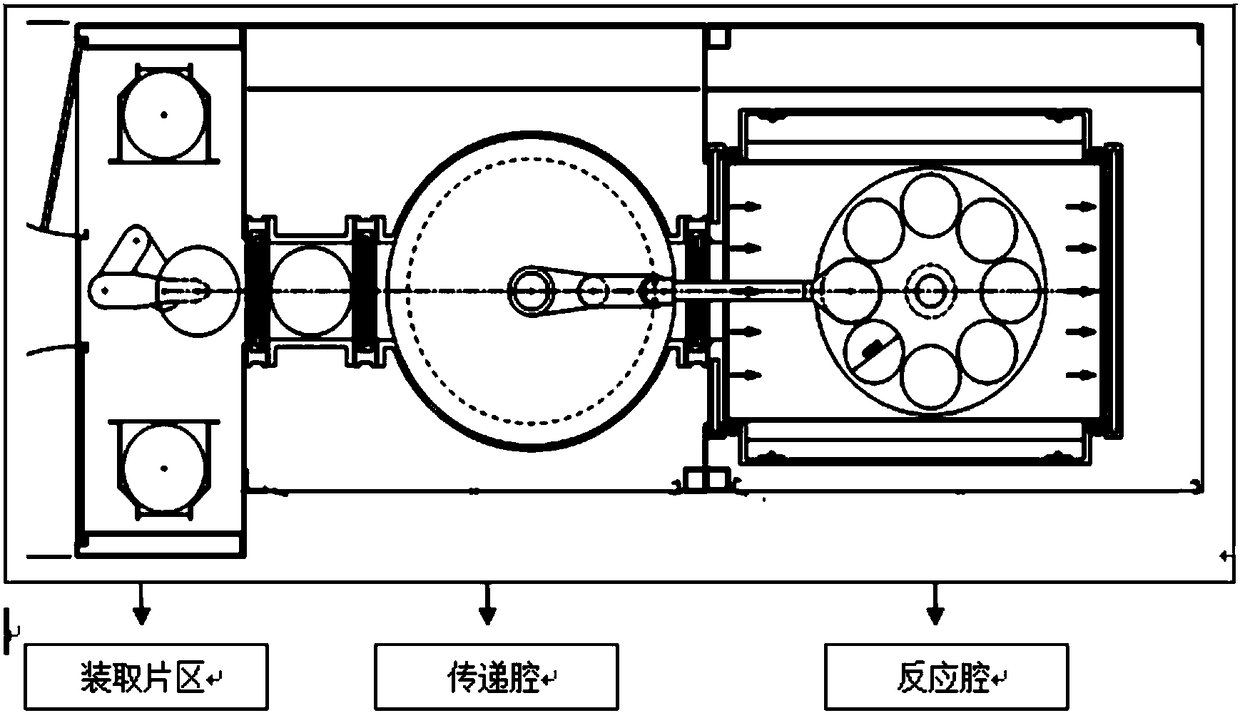

[0023] B. Reactor cleaning: The quartz bell jar and quartz support must be carefully cleaned before high-resistance epitaxy to remove impurity atoms and residues adsorbed on the inner wall of the quartz reactor and quartz parts;

[0024] C. Graphite pedestal treatment: before growing epitaxy, the remaining silicon and impurities on the surface of the pedestal are treated with HCl gas;

[0025] D. Epitaxial vapor phase etching: HCl polishing, at 1080°C, select the HCl flow rate to be 1-2L / min, the polishing time is 2min, and the large flow rate of H after polishing is completed. 2 Purge for 3 minutes; the purpose of vapor ...

Embodiment 1

[0028] A kind of preparation method of the epitaxial wafer for 8-inch high-power IGBT component of the present invention comprises the following steps:

[0029] A. Preparing the substrate sheet: select an 8-inch substrate sheet doped with phosphorus, with a resistivity of 3-25Ω·cm, and the back-sealing structure is polycrystalline (Poly) back-sealing mode;

[0030] B. Reactor cleaning: The quartz bell jar and quartz support must be carefully cleaned before high-resistance epitaxy to remove impurity atoms and residues adsorbed on the inner wall of the quartz reactor and quartz parts;

[0031] C. Graphite pedestal treatment: before growing epitaxy, the pedestal must be reprocessed;

[0032] D. Epitaxial vapor phase etching: HCl polishing, at 1080°C, select the HCl flow rate as 1L / min, the polishing time is 2min, and the large flow rate of H after the polishing is completed. 2 Purge for 3 minutes; the purpose of vapor phase corrosion is to remove the natural oxide layer on the s...

Embodiment 2

[0035] A kind of preparation method of the epitaxial wafer for 8-inch high-power IGBT component of the present invention comprises the following steps:

[0036] A. Preparing the substrate sheet: select an 8-inch substrate sheet doped with phosphorus, with a resistivity of 3-25Ω·cm, and the back-sealing structure is polycrystalline (Poly) back-sealing mode;

[0037] B. Reactor cleaning: The quartz bell jar and quartz support must be carefully cleaned before high-resistance epitaxy to remove impurity atoms and residues adsorbed on the inner wall of the quartz reactor and quartz parts;

[0038] C. Graphite pedestal treatment: before growing epitaxy, the pedestal must be reprocessed;

[0039] D. Epitaxial vapor phase etching: HCl polishing, at 1080°C, select the HCl flow rate as 1L / min, the polishing time is 2min, and the large flow rate of H after the polishing is completed. 2 Purge for 3 minutes; the purpose of vapor phase corrosion is to remove the natural oxide layer on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com