Liquid culture device for plant cells and organs

A culture device and liquid culture technology, applied in the field of cell culture, can solve the problems of increasing the probability of contamination, limiting the growth of culture, increasing contamination, etc., and achieve the effects of promoting gas exchange, reducing gas supply costs, and reducing secondary operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

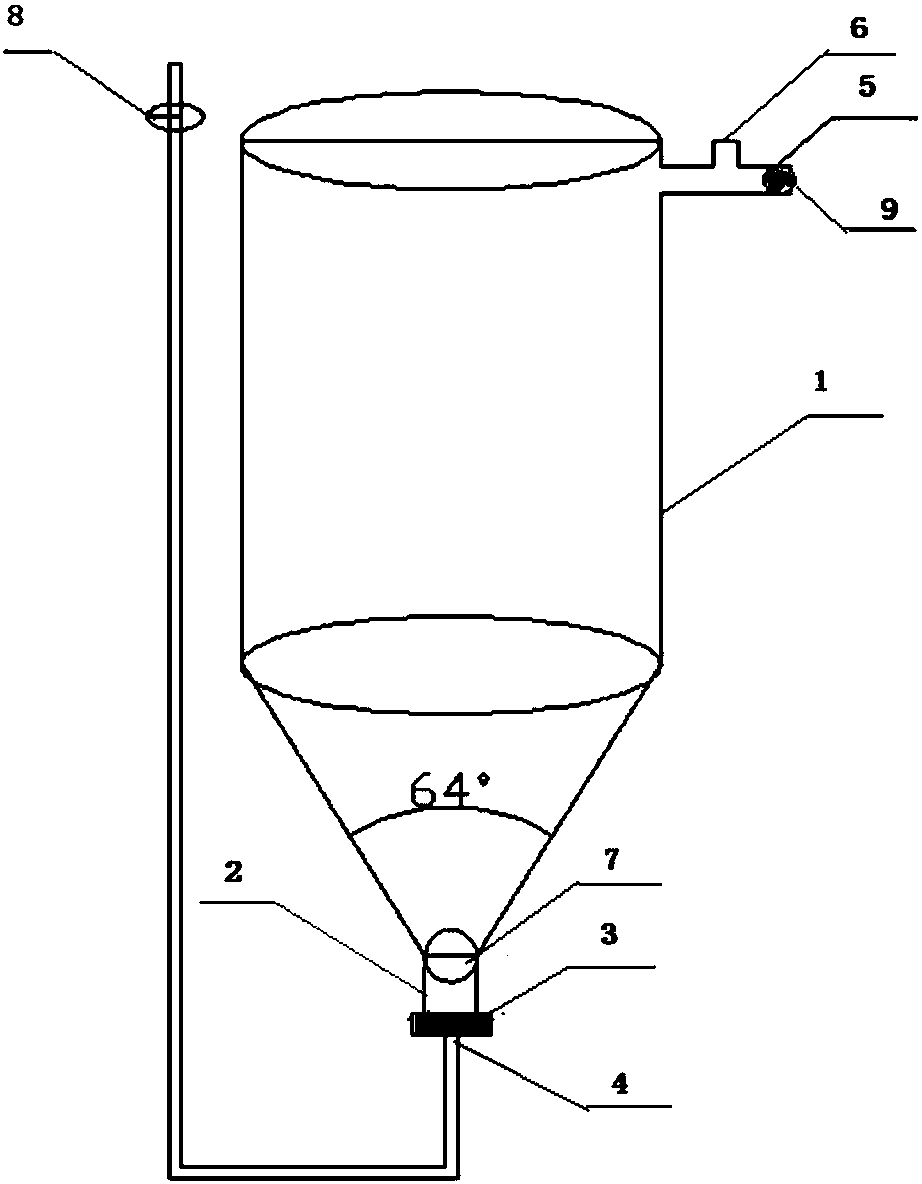

[0045] A plant cell and organ liquid culture device, comprising a culture tank 1 (made of PC that can withstand high pressure sterilization at 121°C, with a capacity of 40L), an inoculation port 2 and an air inlet 4 located at one end of the culture tank 1 , the diameter of the inoculation port 2 is 10cm; and the exhaust port at the other end of the tank; wherein, the tank is cylindrical and conical, and the angle of the cone of the culture tank 1 is 64°C, and the top of the cone is set The inoculation port 2, the height of the inoculation port 2 is 12cm, and the inoculation port 2 cooperates with the sealing cover 3; the exhaust port is arranged on the side of the cylinder near its bottom surface; the air inlet 4 is arranged on the sealing cover 3, and the The inoculation port 2 is a screw port, and the sealing cover 3 is a double-port screw sealing cover, the upper port of which is connected to the air intake pipe, and the lower port is connected to the inoculation port 2 of ...

Embodiment 2

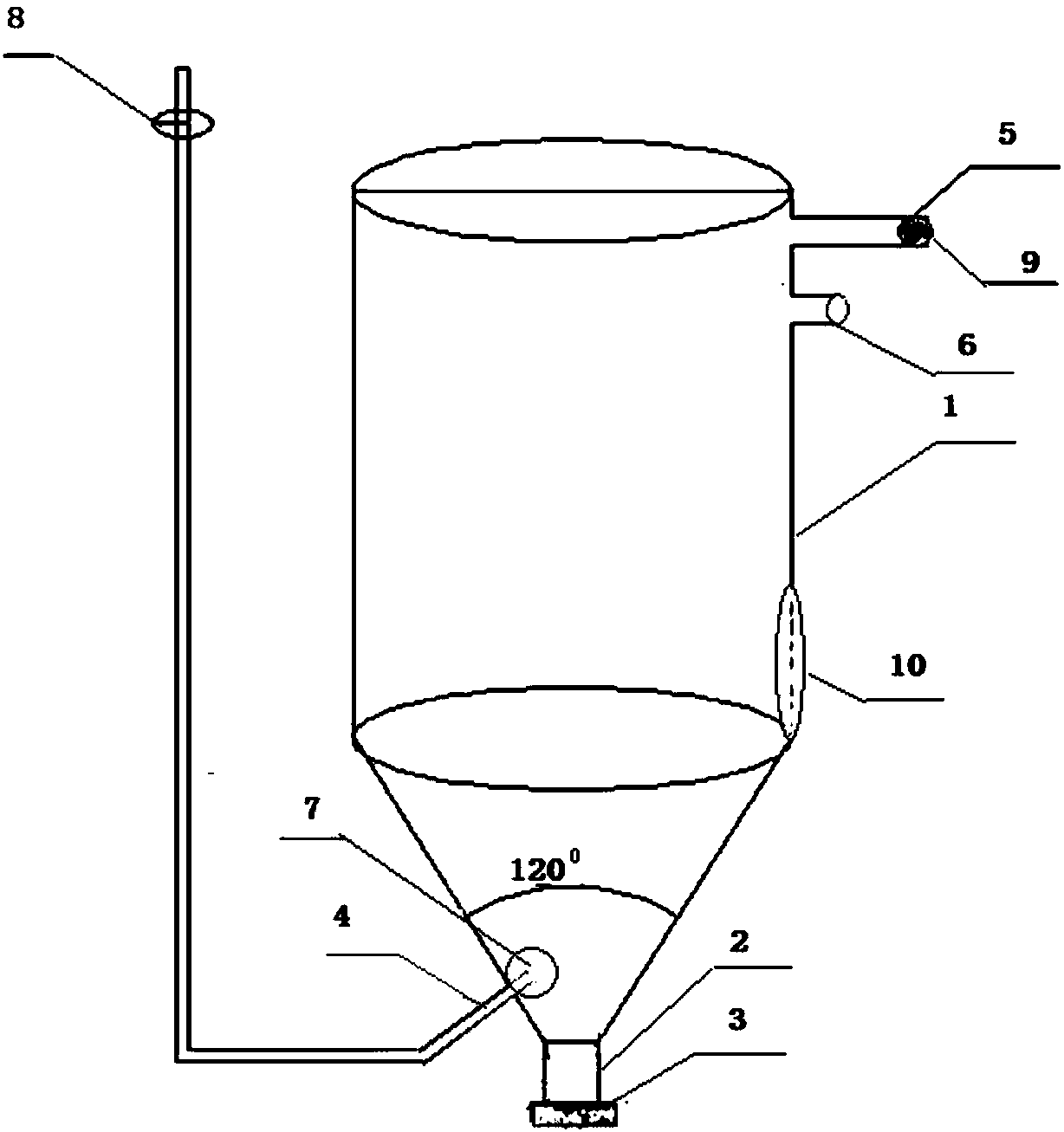

[0051] A liquid culture device for plant cells and organs, comprising a culture tank 1 (made of PC that can withstand autoclaving at 121°C, with a capacity of 100L), an inoculation port 2 and an air inlet at one end of the culture tank 1 4. The diameter of the inoculation port 2 is 10 cm; and the exhaust port at the other end of the tank; wherein, the tank is cylindrical and conical, and the angle of the cone of the culture tank 1 is 120°C, and the top of the cone is The inoculation port 2 is set, and the height of the inoculation port 2 is 8cm, and the inoculation port 2 cooperates with the sealing cover 3; the exhaust port is arranged on the side of the cylinder near its bottom surface; the air inlet 4 is arranged on the inclined plane of the conical tank body Above, the air inlet 4 is connected to the air inlet pipe, and the gas required for cultivation is introduced into the cultivation tank body 1 .

[0052] The side of the cylinder of the culture tank 1 close to the exha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com