C3N4-supported acid/alkali bifunctional MOFs-based composite catalyst, and preparation method and application thereof

An acid-base bifunctional, composite catalyst technology, applied in catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc. , the low pH of the catalyst, etc., to promote the isomerization process and dehydration reaction, increase the yield, and achieve the effect of easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

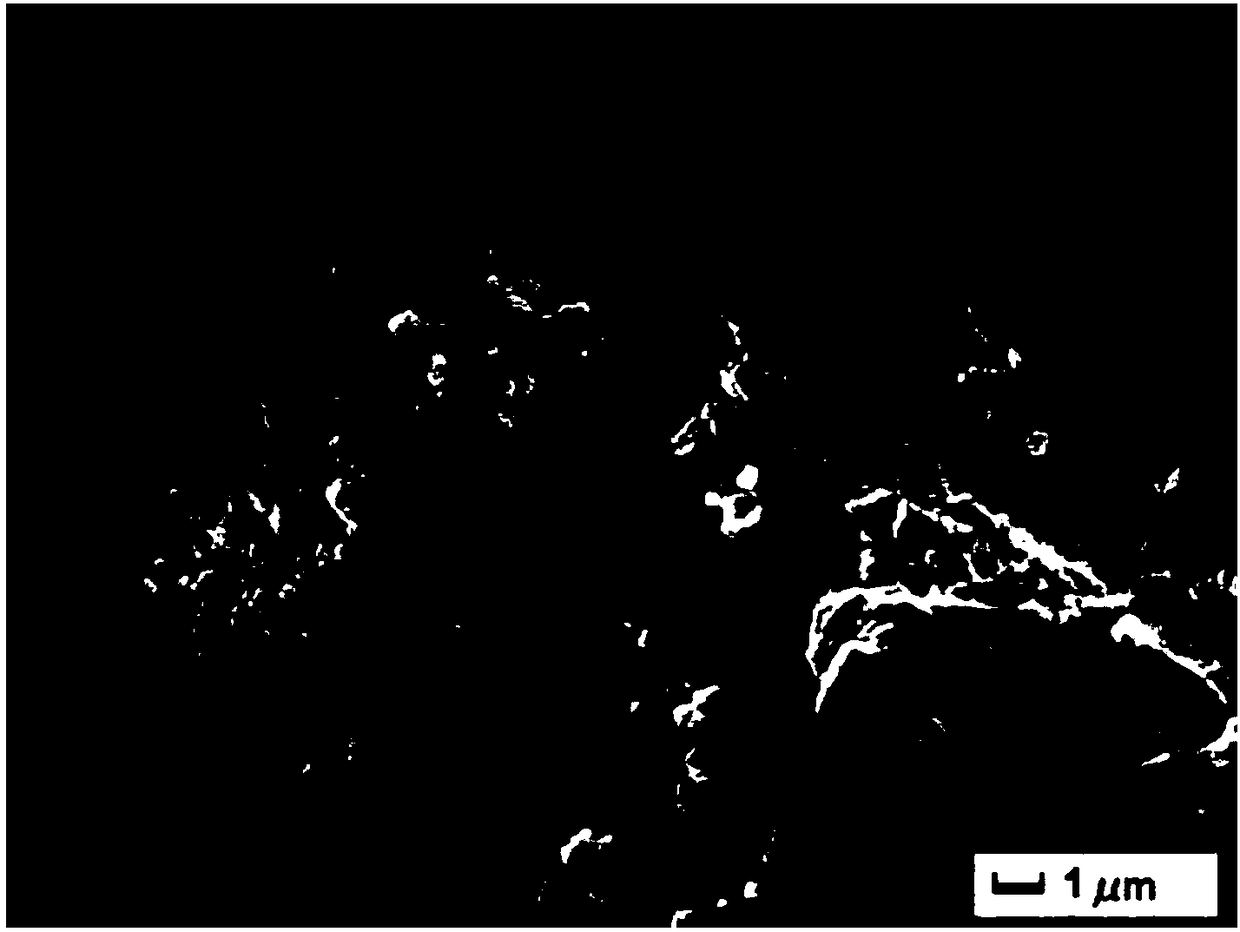

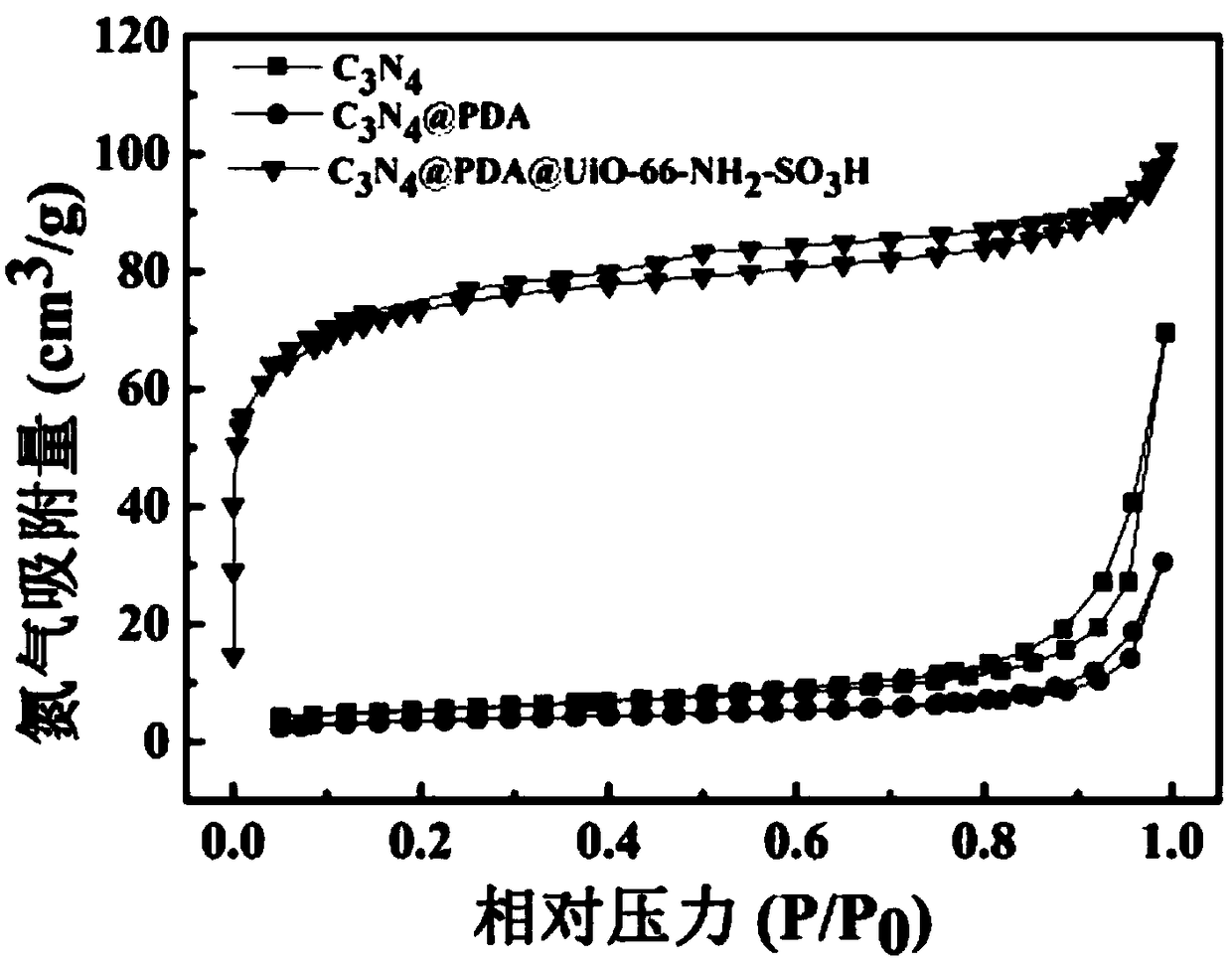

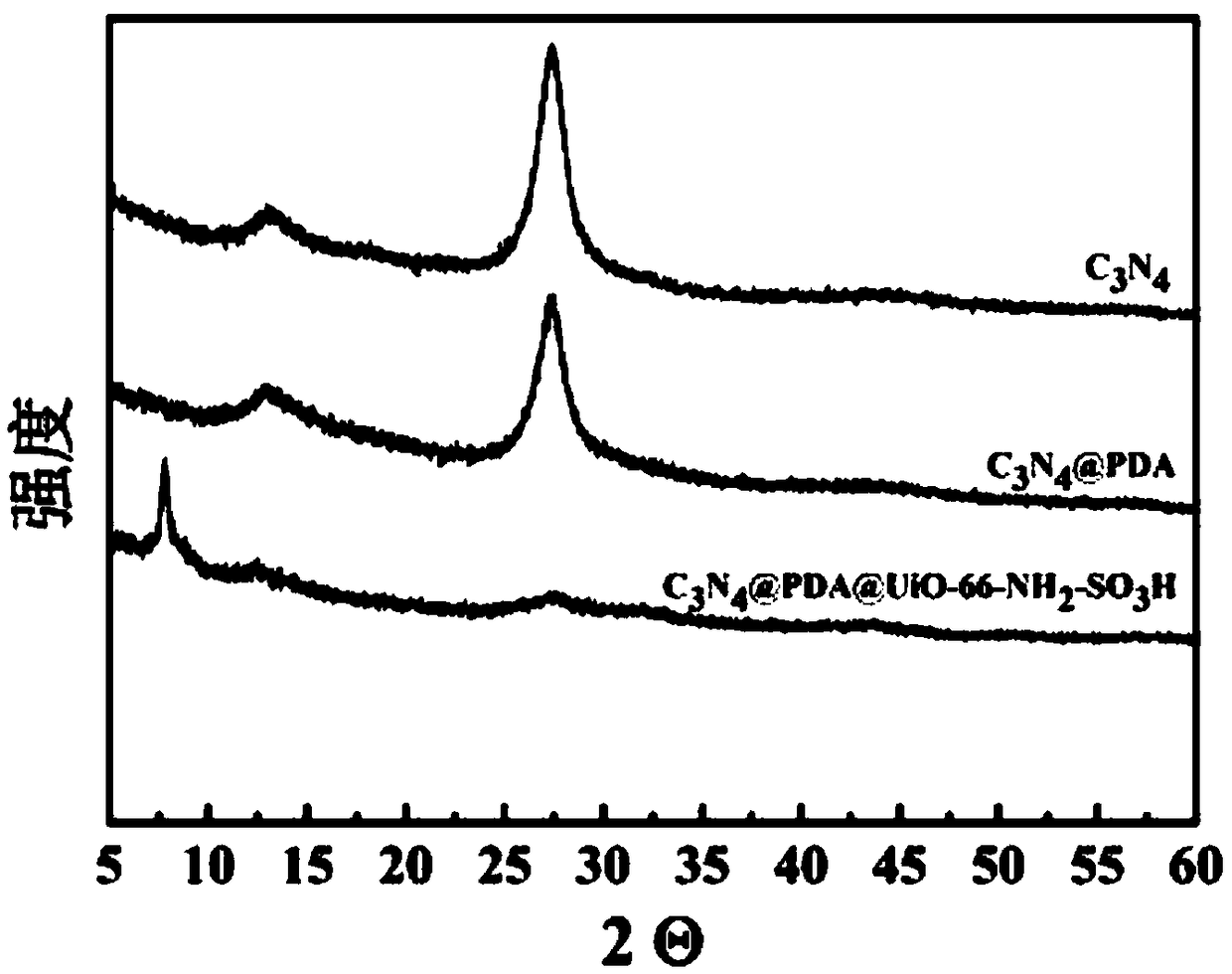

[0031] 1.C 3 N 4 @PDA@UiO-66-NH 2 -SO 3 The preparation method of H is characterized in that it is carried out according to the following steps:

[0032] (1) 250mg dopamine hydrochloride was dissolved in 250mL Tris buffer solution, then 1g C 3 N 4 Add to the mixing system and disperse evenly. Then the mixed system was stirred and reacted in a water bath at 20° C. for 12 h. After the reaction, the product was centrifuged and washed three times with deionized water. The washed product was dried under vacuum at 100 °C to obtain C 3 N 4 @PDA composites.

[0033] (2) 0.05g of zirconium oxychloride octahydrate, 0.02g of 2-aminoterephthalic acid and 0.03g of monosodium 2-sulfonic acid terephthalate were successively dissolved in 5mL of water / acetic acid (v / v=3:2 ) mixed solution, the mixed system was ultrasonically mixed; then 30mgC 3 N 4 @PDA composite material will be put into the above mixing system, shake well. The mixed system was then placed in a water bath at 80° ...

Embodiment 2

[0052] 1.C 3 N 4 @PDA@UiO-66-NH 2 -SO 3 The preparation method of H is characterized in that it is carried out according to the following steps:

[0053](1) 500mg dopamine hydrochloride was dissolved in 500mL Tris buffer solution, and then 2g C 3 N 4 Add to the mixing system and disperse evenly. Then the mixed system was stirred and reacted in a water bath at 30° C. for 24 h. After the reaction, the product was centrifuged and washed three times with deionized water. The washed product was dried under vacuum at 100 °C to obtain C 3 N 4 @PDA composites.

[0054] (2) 4.65g of zirconium oxychloride octahydrate, 1.31g of 2-aminoterephthalic acid and 1.43g of monosodium 2-sulfonic terephthalate were successively dissolved in 300mL of water / acetic acid (v / v=3:2 ) mixed solution, the mixed system was ultrasonically mixed; then 1800mgC 3 N 4 @PDA composite material will be put into the above mixing system, shake well. The mixed system was then placed in a water bath at 90...

Embodiment 3

[0062] 1.C 3 N 4 @PDA@UiO-66-NH 2 -SO 3 The preparation method of H is characterized in that it is carried out according to the following steps:

[0063] (1) 750mg dopamine hydrochloride was dissolved in 750mL tris buffer solution, then 3g C 3 N 4 Add to the mixing system and disperse evenly. Then the mixed system was stirred and reacted in a water bath at 40° C. for 36 h. After the reaction, the product was centrifuged and washed three times with deionized water. The washed product was dried under vacuum at 100 °C to obtain C 3 N 4 @PDA composites.

[0064] (2) 9.3g of zirconium oxychloride octahydrate, 2.61g of 2-aminoterephthalic acid and 3.86g of monosodium 2-sulfonic terephthalate were successively dissolved in 600mL of water / acetic acid (v / v=3:2 ) mixed solution, the mixed system was ultrasonically mixed; then 3600mgC 3 N 4 @PDA composite material will be put into the above mixing system, shake well. The mixed system was then placed in a water bath at 98° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com