Production method of nitrogen slow-release type organic fertilizer

A technology of organic fertilizers and production methods, applied in the preparation of organic fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve the problems of hindering the growth and development of crops, lack of fertilizers, difference in fertilizer efficiency, etc., so as to reduce production costs, improve utilization, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

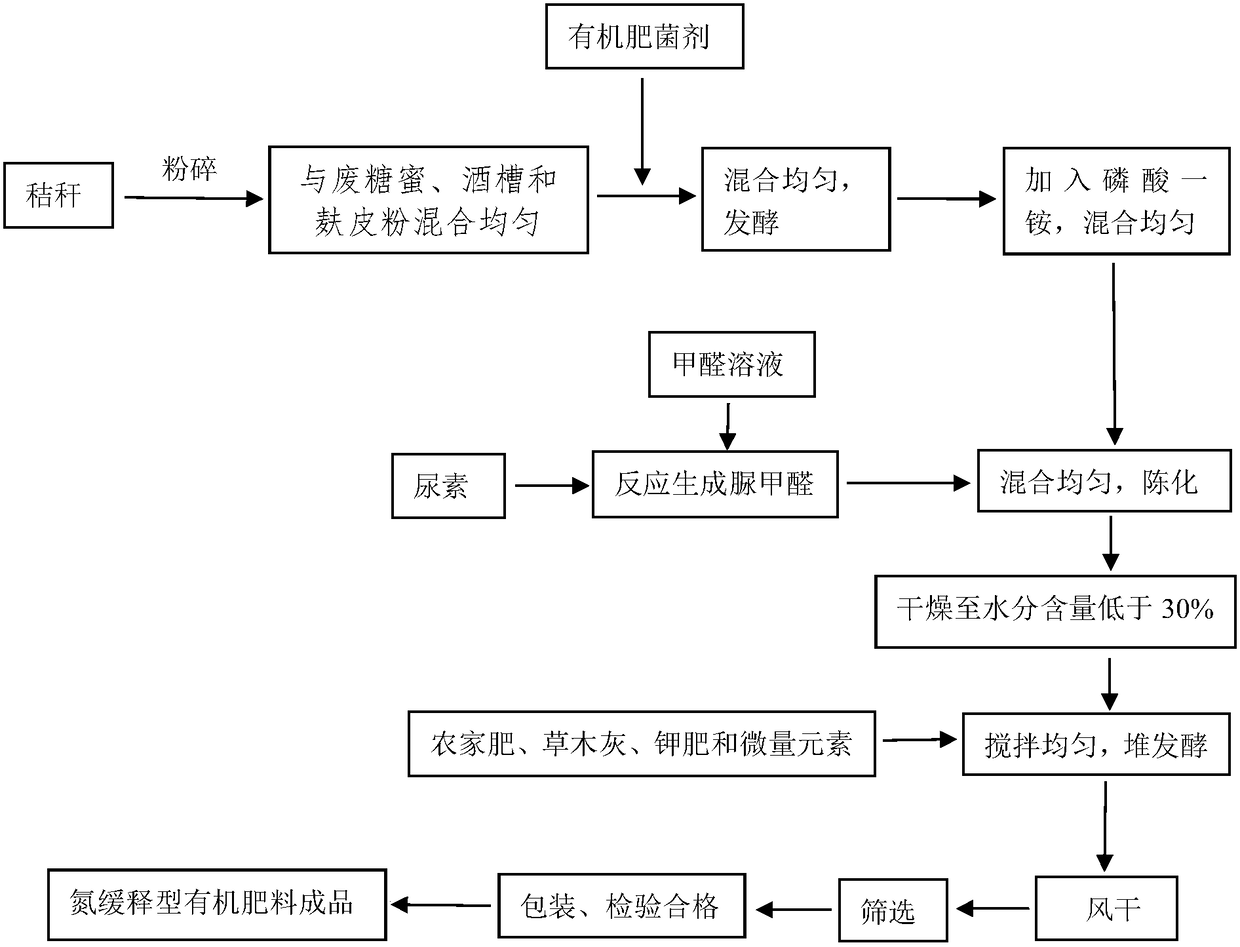

[0037] A method for producing nitrogen slow-release organic fertilizer, comprising the following steps:

[0038] ① Put 400 parts by weight of straw into the pulverizer, pulverize to a particle size of 4mm, add waste molasses, wine tank and bran powder and mix evenly, then add organic fertilizer agent with 0.5% of straw weight, mix evenly, Cover the film, place it in a fermentation tank at 45°C for 15 days, and turn it over 3 times during the period, lift the film after turning over the last time, control the temperature at 38°C, and continue ventilation and fermentation for 6 days to obtain fermented organic raw materials; The pile diameter during the process is 1.5m, and the pile height is 1.2m; the bran powder is one or a mixture of peanut bran, rice bran, wheat bran, soybean bran, and rapeseed bran; the straw, waste molasses, The weight ratio=35:7:3:11 of distiller tank and bran powder; Described organic manure agent is Saccharomyces cerevisiae;

[0039] 2. Adding monoammo...

Embodiment 2

[0045] A method for producing nitrogen slow-release organic fertilizer, comprising the following steps:

[0046] ① Put 500 parts by weight of straw into the pulverizer, pulverize to a particle size of 10mm, add waste molasses, wine tank and bran powder and mix evenly, then add 2% organic fertilizer by weight of straw, mix evenly, Cover with a film, place it in a fermentation tank at 55°C for 25 days, turn over the pile 5 times during the period, remove the film after turning over the last time, control the temperature at 45°C, and continue ventilation and fermentation for 10 days to obtain fermented organic raw materials; The pile diameter during the process is 2m, and the pile height is 1.6m; the bran powder is one or a mixture of peanut bran, rice bran, wheat bran, soybean bran, rapeseed bran; the straw, waste molasses, wine The weight ratio=40:7:5:13 of trough and bran powder; Described organic fertilizer agent is lactobacillus plantarum;

[0047] 2. Adding monoammonium ph...

Embodiment 3

[0053] A method for producing nitrogen slow-release organic fertilizer, comprising the following steps:

[0054] ① Put 410 parts by weight of straw into a pulverizer, pulverize to a particle size of 5mm, add waste molasses, wine tank and bran powder and mix evenly, then add 0.6% organic fertilizer by weight of straw, mix evenly, Cover the film, place it in a fermentation tank at 46°C for 16 days, turn over the pile 3 times during the period, remove the film after turning over the pile for the last time, control the temperature at 39°C, and continue ventilation and fermentation for 7 days to obtain fermented organic raw materials; The diameter of the pile during the process is 1.6m, and the pile height is 1.3m; the bran powder is one or a mixture of peanut bran, rice bran, wheat bran, soybean bran, rapeseed bran; the straw, waste molasses, The weight ratio=36:7:3.5:11.5 of wine tank and bran powder; Described organic fertilizer is Bacillus subtilis;

[0055] 2. Adding monoammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com