Method for preparing (Cu,Fe)3O4 spinel coating through magnetron sputtering method and application thereof

A technology of spinel coating and magnetron sputtering, which is applied in the direction of coating, sputtering coating, metal material coating process, etc., can solve the problems of difficult control of composition and thickness, slow film preparation rate and substrate bonding force. Poor and other problems, to achieve the effect of improving oxidation resistance and electrical conductivity, compact structure, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: This example uses SUS 430 stainless steel as the matrix (Cr: 16mass%)

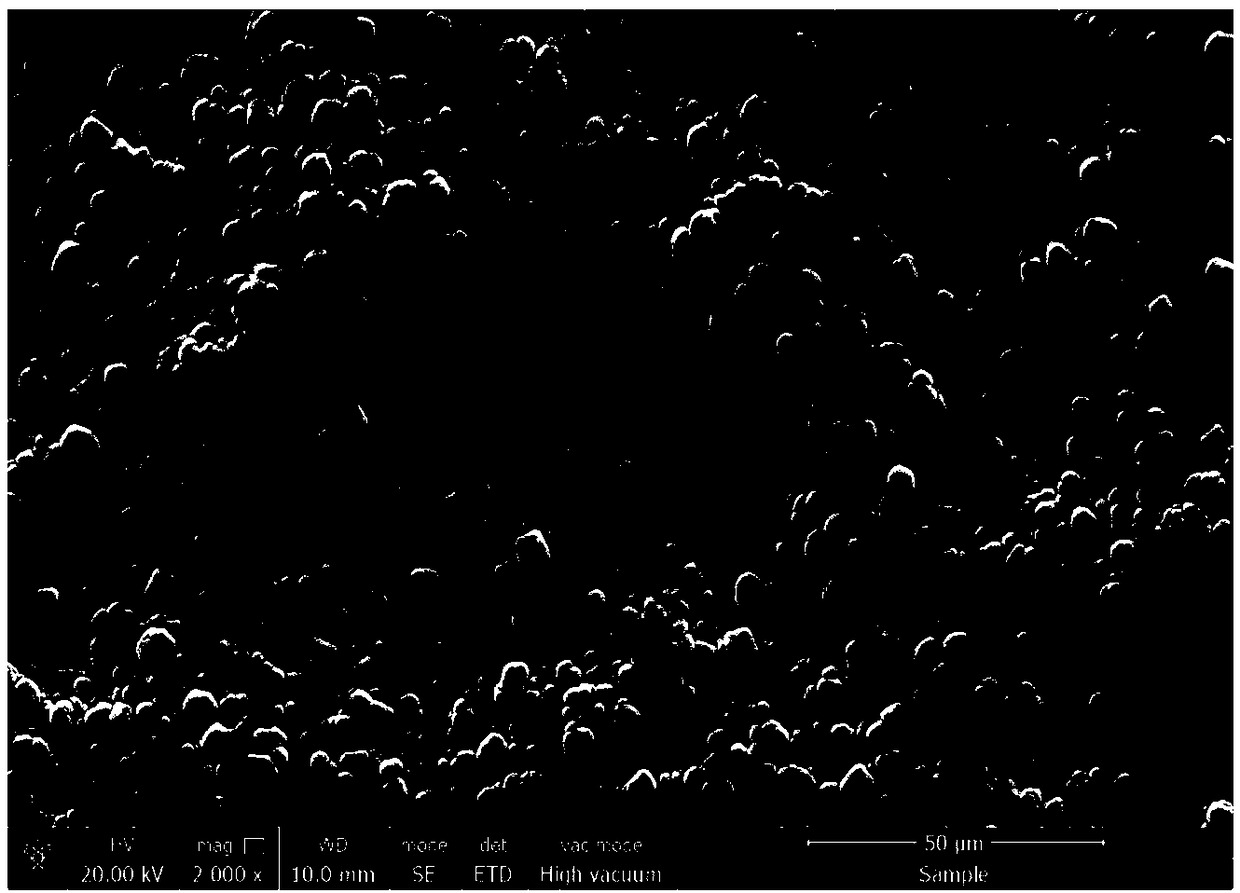

[0027] (1) Pretreatment: Use 240#, 400#, 600# SiC water scrubbing paper to grind the surface of the SUS430 stainless steel substrate, and perform edge grinding and chamfering; the substrate is sandblasted after sandblasting, and the pressure range of compressed air during sandblasting is 0.5MPa, the sand used is silica; after the substrate is sandblasted, ultrasonically cleaned with acetone for 15min; the cleaned sample is pre-oxidized in the air at 800℃ for 100h to form Cr with a thickness of about 2μm on the stainless steel surface 2 O 3 And (Mn,Cr) 3 O 4 Oxide layer

[0028] (2) Sputtering deposition to obtain alloy coating: a Cu-Fe alloy target (33% Cu content, 67% Fe content) as the cathode, the substrate as the anode, sputtering current 3.0A, sputtering pressure 0.15Pa, sputtering The injection temperature is 200℃, the sputtering time is 2h, and the Cu-Fe alloy coating with a thickness o...

Embodiment 2

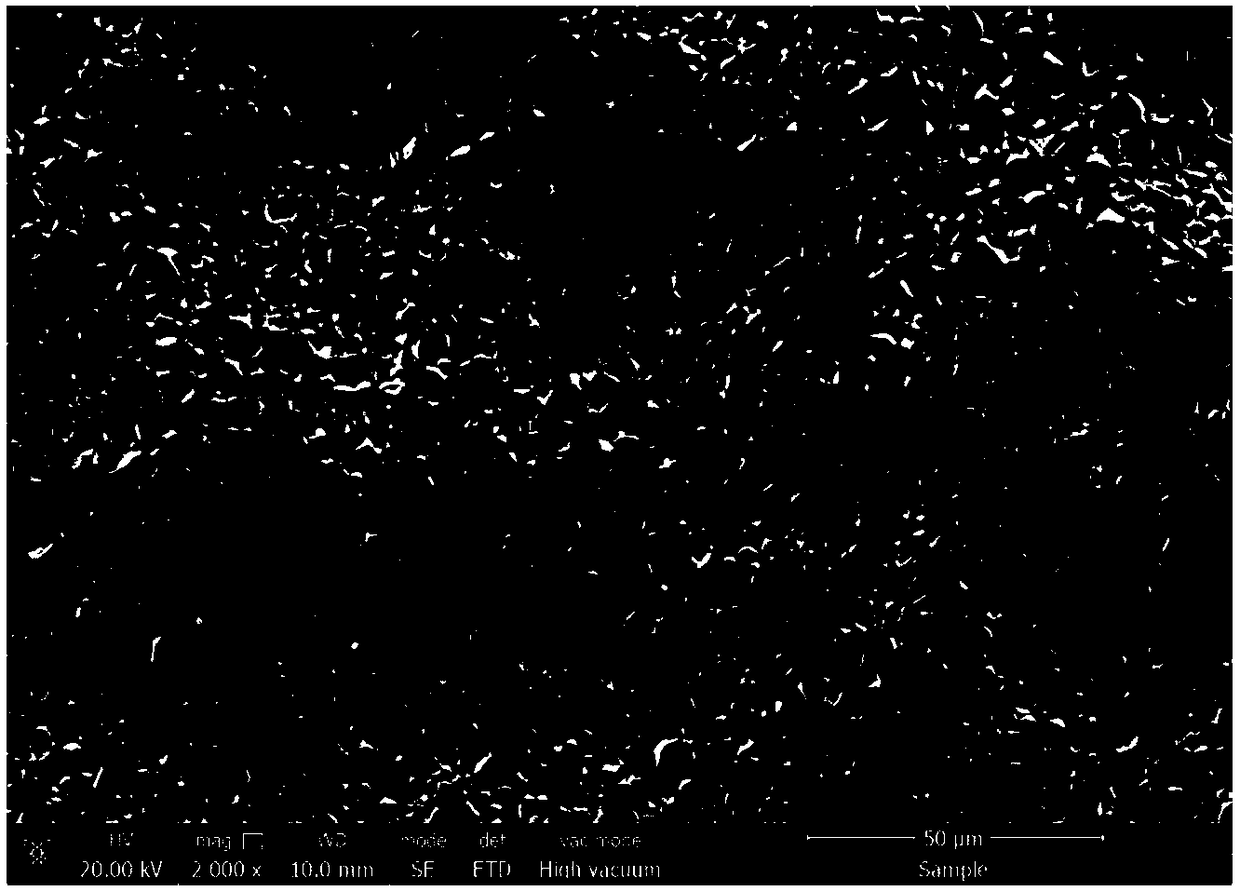

[0032] Example 2 This example uses crofer22APU stainless steel as the substrate (Cr: 22mass%) (1) Pretreatment: Use 240#, 400#, 600# SiC water abrasive paper to polish the surface of crofer22APU stainless steel substrate, and perform edge grinding and chamfering treatment ; Sandblasting is carried out after the substrate is polished, the compressed air pressure range during sandblasting is 0.3MPa, and the sand used is silica; after the substrate is sandblasted, ultrasonically cleaned with acetone for 10 minutes; the cleaned sample is placed in the air at 650℃ Pre-oxidation for 150h to form Cr with a thickness of about 2.5μm on the surface of stainless steel 2 O 3 And (Mn,Cr) 3 O 4 Oxide layer

[0033] (2) Sputtering deposition to obtain alloy coating: a Cu-Fe alloy target (30% Cu content, 70% Fe content) as the cathode, the substrate as the anode, sputtering current 3.0A, sputtering pressure 0.10Pa, sputtering The injection temperature is 200℃, the sputtering time is 0.5h, and th...

Embodiment 3

[0035] Example 3 This example uses AISI 430 stainless steel as the matrix (Cr:18mass%)

[0036] (1) Pretreatment: Use 240#, 400#, 600# SiC water scrubbing paper to polish the surface of AISI430 stainless steel substrate in turn, and perform edge grinding and chamfering treatment; after polishing the substrate, perform sandblasting. The pressure range of compressed air during sandblasting is 0.4MPa, the sand used is silica; after the substrate is sandblasted, ultrasonically cleaned with acetone for 13min; the cleaned sample is pre-oxidized in the air at 750℃ for 200h to form Cr with a thickness of about 3μm on the stainless steel surface 2 O 3 And (Mn,Cr) 3 O 4 Oxide layer

[0037] (2) Sputtering deposition to obtain alloy coating: Cu-Fe alloy target (Cu content 40%, Fe content 60%) is used as the cathode, the substrate is used as the anode, the sputtering current is 3.0A, the sputtering pressure is 0.13Pa, and the sputtering The injection temperature is 200℃, the sputtering time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com