A kind of anti-ultraviolet nano-zinc oxide composite textile fabric and its preparation method

A technology of nano-zinc oxide and textile fabrics, applied in the direction of textiles and papermaking, biochemical fiber treatment, physical treatment, etc., can solve the problems of unevenness, reduced service life of composite fabrics, high cost of magnetron sputtering, etc., and achieve good uniformity , combined with good fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of an anti-ultraviolet nano-zinc oxide composite textile fabric, which adopts the combination of supercritical fluid assisted infiltration method and thermal reduction method, including the following steps:

[0043] (1) Ultrasonic cleaning of 20-99 parts of textile fabrics in 0.5-80 parts of ethanol and acetone solution for 10-20 minutes;

[0044] (2) Clean the textile fabric after ultrasonic cleaning in step (1) with deionized water, and dry it in an oven at 50-70°C for later use;

[0045](3) Dissolving 0.5-40 parts of zinc salt in 0.5-80 parts of co-solvent, and then adding it to supercritical fluid equipment, putting the textile fabric dried in step (2) into supercritical fluid equipment, Feed CO into supercritical fluid equipment 2 gas, supercritical CO 2 It has the effect of plasticizing expansion and strong penetration on textile fabrics, and zinc salts 2 Enter the fiber interior of the textile fabric, an...

Embodiment 1

[0053] The polyester fabric with a size of 10cm×10cm was ultrasonically cleaned with acetone and ethanol solutions for 15 minutes, then cleaned with deionized water, and dried in an oven for later use; then 1.5g of zinc acetylacetonate was dissolved in 25ml of ethanol, and supercritical fluid was added In the equipment; put the polyester fabric after ultrasonic cleaning into the supercritical fluid equipment, and pass CO into the supercritical fluid equipment 2 Gas, under the condition of pressure 15Mpa and temperature 80℃ for 6h, take out the polyester fabric; then put the supercritically reacted polyester fabric into the hydrothermal reaction kettle, heat it at 180℃ for 4h, finally take out the polyester fabric and wash it with water and dry to obtain the anti-ultraviolet nano-zinc oxide composite textile fabric.

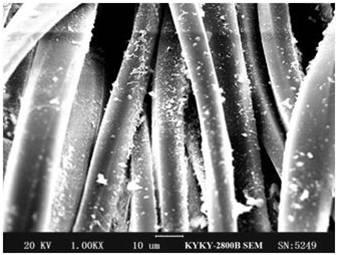

[0054] Observed under scanning electron microscope, the electron micrograph of the anti-ultraviolet nano-zinc oxide composite textile fabric that obtains is as fo...

Embodiment 2

[0056] The polyester fabric with a size of 10cm×10cm was ultrasonically cleaned with acetone and ethanol solutions for 15 minutes, then cleaned with deionized water, and dried in an oven for later use; then 1g of zinc acetylacetonate was dissolved in 25ml of ethanol and added to supercritical fluid equipment Middle; Put the polyester fabric after ultrasonic cleaning into the supercritical fluid equipment, and pass CO2 into the supercritical fluid equipment 2 Gas, under the condition of pressure 10Mpa, temperature 60 ℃ for 4h, take out the polyester fabric; then put the supercritically reacted polyester fabric into the hydrothermal reaction kettle and heat it at 120℃ for 3h, finally take out the polyester fabric and wash it with water and dry it. The anti-ultraviolet nano-zinc oxide composite textile fabric is obtained.

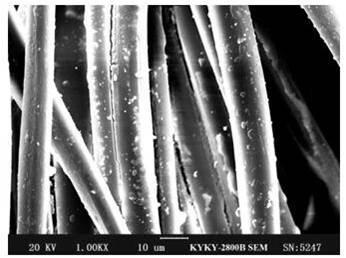

[0057] Observed under scanning electron microscope, the electron micrograph of the anti-ultraviolet nano-zinc oxide composite textile fabric that obtains is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com