Titanium dioxide nanotube array bod sensor and its preparation method and application

A nanotube array and titanium dioxide technology, which is applied in the direction of instruments, scientific instruments, and material electrochemical variables, can solve the problems of failure to be practically applied, unstable BOD measurement results, poor reproducibility, etc., and achieve fast and accurate measurement The effect of high precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0043] Embodiment 1 (undoped)

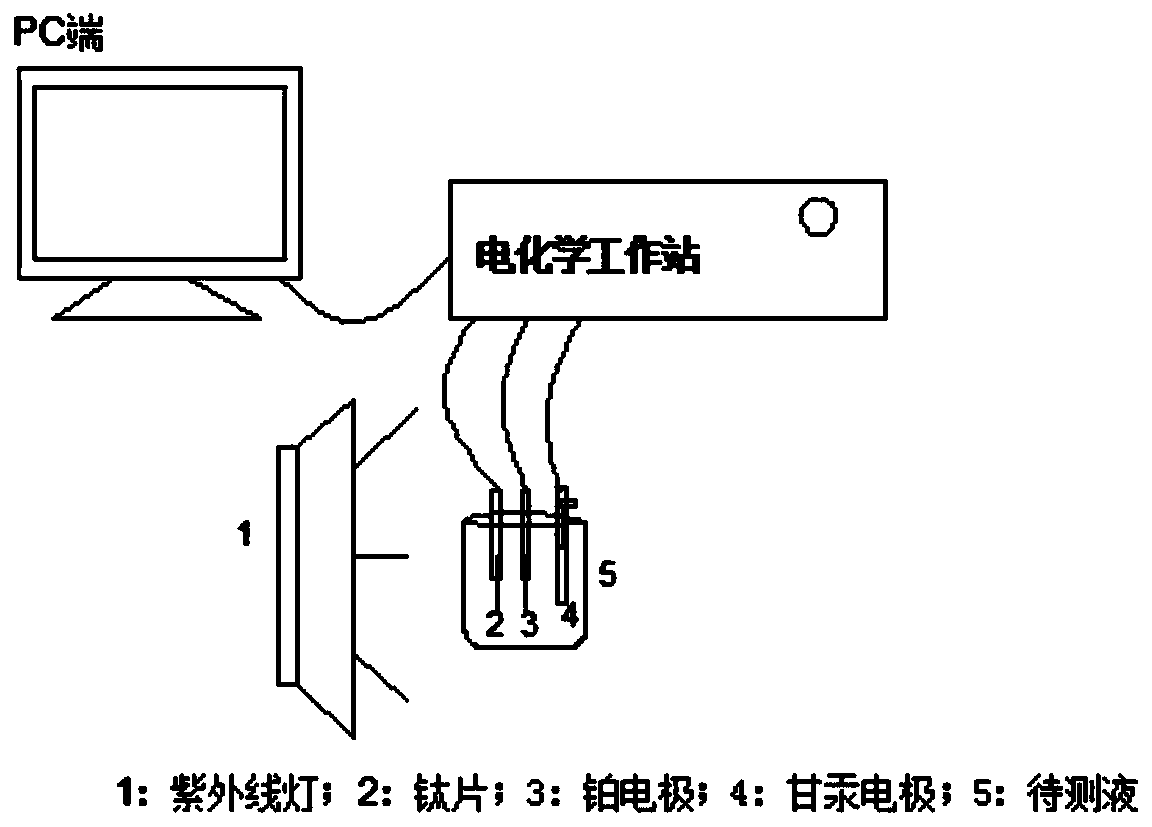

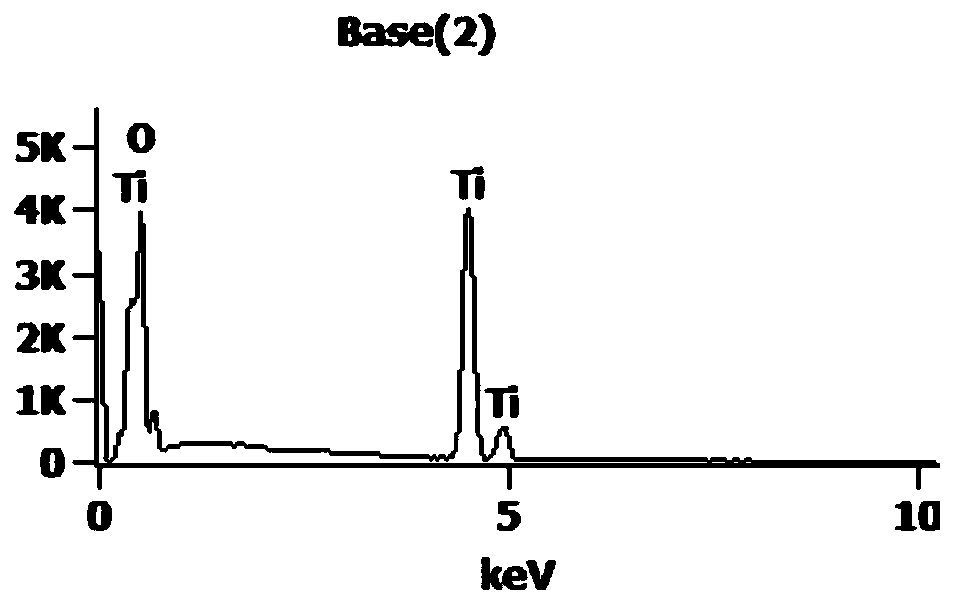

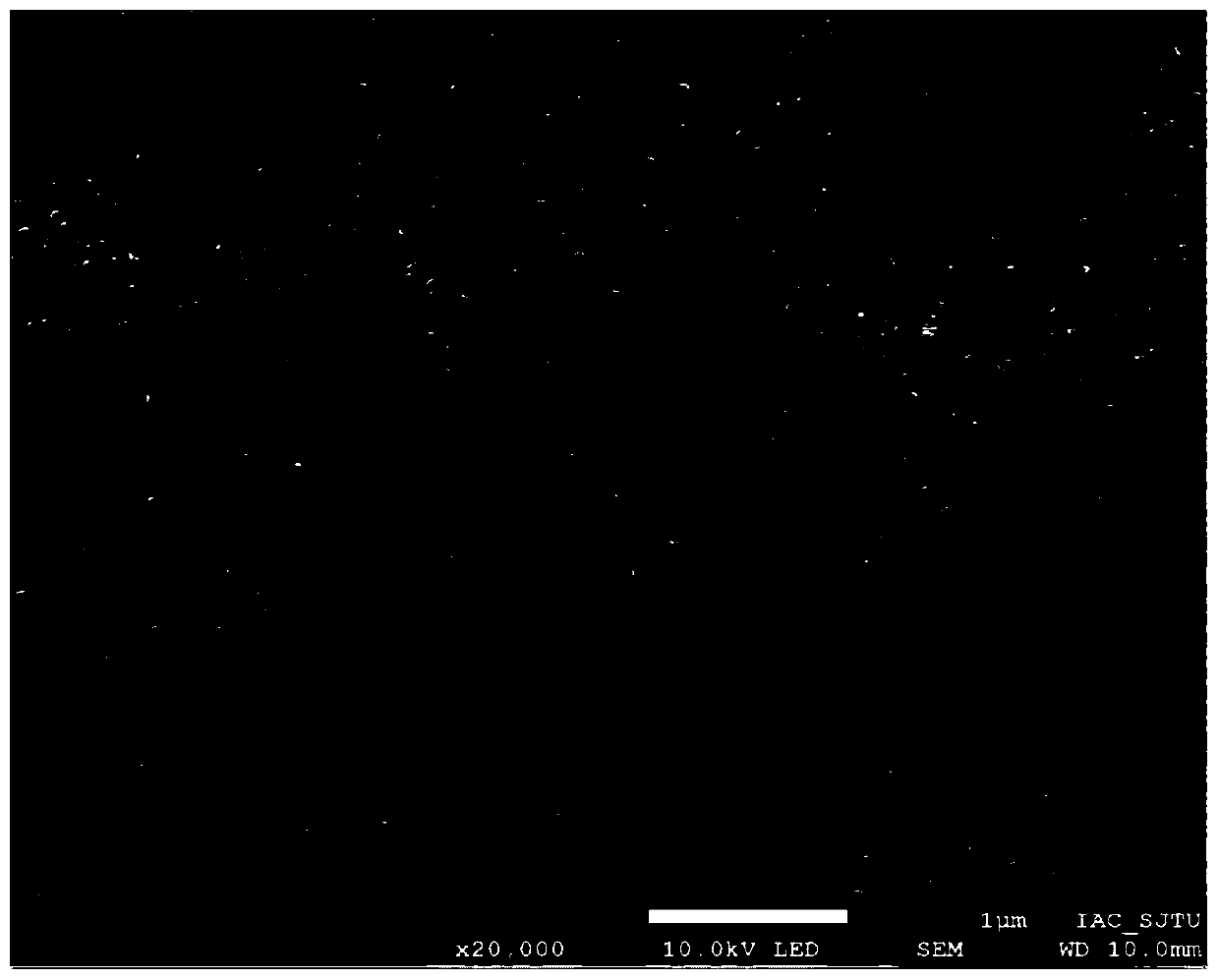

[0044] The purchased titanium plates were cut into 1.5cm×1.5cm titanium pieces, washed with an aqueous solution of 1.0% sodium dodecylbenzenesulfonate and 8% NaOH, and then washed with deionized water, acetone, and deionized water respectively. After cleaning for 15 minutes, under a voltage of 15 volts, using glycerol and water with a volume ratio of 4:1 as the electrolyte and 0.5% ammonium fluoride as the electrolyte, the titanium dioxide nanotube array BOD sensor was obtained after electrolyzing the titanium sheet for two hours. After testing, the doped titania nanotube array is mainly composed of the following components by weight percentage: adopt EDX to measure and contain 81.71% Ti and 18.29% O (see Table 1 and figure 2 (LiveTime:30.0sec.Acc.Voltage:10.0kV Take Off Angle:30.0deg.)); The length of the doped titania nanotube array is 5 μm, and the tube diameter is 130-150nm. image 3 .

[0045] Table 1

[0046] Element Line N...

Embodiment approach 2

[0051] Embodiment 2 (doping C, N)

[0052] 0.5mm titanium alloy (titanium content 99.5%) is used as raw material, laser cut into a square titanium sheet with a size of 15mm×15mm, and polished to no scratches. Follow the sequence of deionized water, acetone, and deionized water to ultrasonically clean for 15 minutes to remove the grease on the surface of the titanium sheet. Soak in 7% HF, 35% HNO3, 7% HCl, 51% H2O ratio solution for 60s, wash with deionized water and dry in an oven at 40°C. After drying, fix it with a platinum sheet electrode clip and put it into an anodic oxidation tank. Use 400ml of glycerol aqueous solution (volume ratio 4:1) containing 0.5wt% NH4F as the electrolyte, and electrolyze with a DC voltage of 15V for 2 hours to obtain titanium dioxide nanotubes. After drying, put it into a 10% concentration of urea solution and immerse it for 30 minutes, dry it again, put it into a muffle furnace for heat treatment at 450 degrees for 3 hours, and obtain a C, N-d...

Embodiment approach 3

[0058] Embodiment 3 (doping C, N)

[0059]0.5mm titanium alloy (titanium content 99.5%) is used as raw material, laser cut into a square titanium sheet with a size of 15mm×15mm, and polished to no scratches. Follow the sequence of deionized water, acetone, and deionized water to ultrasonically clean for 15 minutes to remove the grease on the surface of the titanium sheet. Soak in 10% HF, 40% HNO3, and 5% HCl aqueous solution for 60 seconds, wash with deionized water, and dry in an oven at 40 degrees. After drying, fix it with a platinum sheet electrode clip and put it into an anodic oxidation tank. Use 400ml of glycerol aqueous solution (volume ratio 4:1) containing 0.2wt% NH4F as the electrolyte, and electrolyze with a DC voltage of 15V for 2 hours to obtain titanium dioxide nanotubes. After drying, immerse in 15% urea solution for 30 minutes, dry again, put it into a muffle furnace for heat treatment at 450 degrees for 3 hours, and obtain C and N-doped titanium dioxide nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com