Building refractory material and preparation method thereof

A refractory material and building technology, applied in the field of building refractory materials and its preparation, can solve the problems of poor fire resistance, bending resistance and pressure resistance, and achieve the effect of good thermal shock resistance and high oxidation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

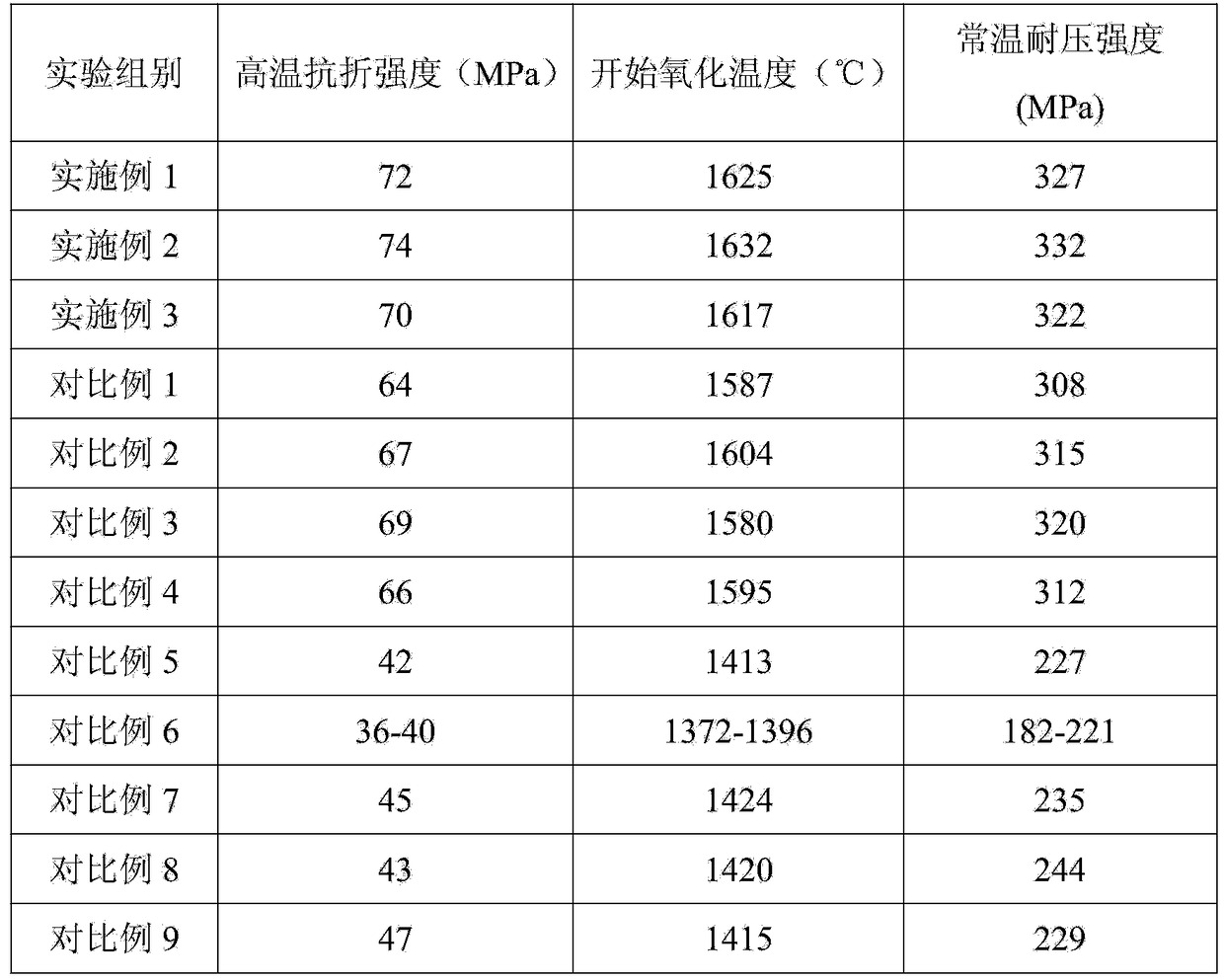

Examples

preparation example Construction

[0033] The preparation method of described building refractory material, comprises the following steps:

[0034] S1: Wet-grind andalusite, nano-zirconia, flake graphite, silicon carbide, silicon nitride, and silicon dioxide with a planetary ball mill, the motor speed is 600-800r / min, and the ball milling time is 35-45min;

[0035]S2: Add andalusite, nano-zirconia, flake graphite, silicon carbide, silicon nitride, and silicon dioxide obtained in step S1 into the stirring tank in sequence, and pre-mix for 15-25 minutes at a rotation speed of 100-200 r / min;

[0036] S3: Add the mixed material obtained in step S2 into a mixer, then add polyvinyl alcohol, dispersant sodium pyrophosphate, and calcium aluminate cement aggregate in sequence, and mix for 25 to 30 minutes;

[0037] S4: placing the mixed material obtained in step S3 in a pressure molding machine, and pre-press molding at a pressure of 100-150 MPa;

[0038] S5: Place the wet billet obtained in step S4 in a vacuum drying ...

Embodiment 1

[0042] Building refractory materials, in parts by weight, include the following raw materials: 45 parts of andalusite, 12 parts of nano-zirconia with a particle size of 40nm, 33 parts of flake graphite with a size of 0.06mm, 7 parts of silicon carbide, and 4 parts of silicon nitride , 20 parts of distilled water, 35 parts of polyvinyl alcohol, 7 parts of dispersant sodium pyrophosphate, 60 parts of calcium aluminate cement aggregate.

[0043] The preparation method of described building refractory material, comprises the following steps:

[0044] S1: Use a planetary ball mill to wet-grind andalusite, nano-zirconia, flake graphite, silicon carbide, silicon nitride, and silicon dioxide. The ratio of raw material mass to abrasive grain mass is 1:2, and the motor speed is 600r / min. The time is 35 minutes;

[0045] S2: Add andalusite, nano-zirconia, flake graphite, silicon carbide, silicon nitride, and silicon dioxide obtained in step S1 into the stirring tank in sequence, and pre...

Embodiment 2

[0051] Building refractory materials, in parts by weight, include the following raw materials: 76 parts of andalusite, 20 parts of nano-zirconia with a particle size of 60nm, 45 parts of flake graphite with a size of 0.09mm, 18 parts of silicon carbide, and 12 parts of silicon nitride , 38 parts of distilled water, 60 parts of polyvinyl alcohol, 16 parts of dispersant sodium pyrophosphate, 110 parts of calcium aluminate cement aggregate.

[0052] The preparation method of described building refractory material, comprises the following steps:

[0053] S1: Use a planetary ball mill to wet-grind andalusite, nano-zirconia, flake graphite, silicon carbide, silicon nitride, and silicon dioxide. The ratio of raw material mass to abrasive grain mass is 1:2, and the motor speed is 800r / min. The time is 35 minutes;

[0054] S2: Add andalusite, nano-zirconia, flake graphite, silicon carbide, silicon nitride, and silicon dioxide obtained in step S1 into the stirring tank in sequence, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com