Preparing method and application of volatile limette oil

A technology of white lemon and volatile oil, which is applied in the application and preparation of tobacco, essential oils/flavors, etc., which can solve the problems of high production cost, high irritation, and low extraction rate, and achieve pure quality, clear smoke aroma, and improved extraction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

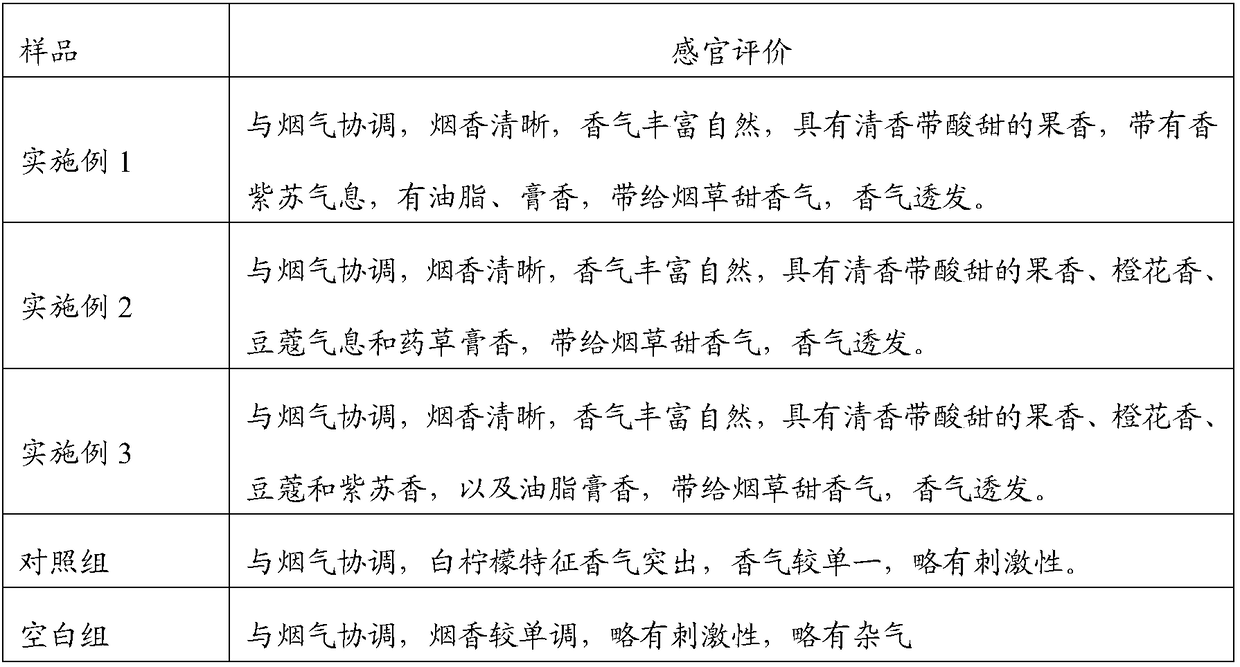

Examples

Embodiment 1

[0021] A preparation method of white lemon volatile oil, comprising the steps of:

[0022] (1) Raw material processing: After cleaning the white lemon fruit, the peel and pulp are separated, the core is removed, the peel and the pulp residue after squeezing the lemon juice are air-dried, and they are put into a low-temperature pulverizer at 2°C and pulverized into a 40-mesh coarse powder , sieve, and vacuumize the raw material powder for 15 minutes by pumping the vacuum, mix the raw material powder and water evenly according to the mass ratio of 1:50, and pour it into the extraction tank;

[0023] (2) Biotransformation: add cinnamic acid, caffeic acid (food grade, account for 0.1% of the white lemon powder mass, proportioning is 1:0.5) in the extraction tank, add compound biological agent (Lactobacillus rhamnosus (L.rhamnosus ), β-glucosidase, α-glucosidase, pectinase, limonin dehydrogenase, all of which are food grade, with enzyme activities of 2000u / g, 500u / g, 5000u / g, 20000...

Embodiment 2

[0028] A preparation method and application of white lemon volatile oil, comprising the steps of:

[0029] (1) Raw material processing: After the white lemon fruit is cleaned, the peel and pulp are separated, the core is removed, the peel and the pulp residue after squeezing the lemon juice are air-dried, and they are put into a low-temperature pulverizer at 3° C. and pulverized into 120-mesh powder. Sieve, vacuumize the raw material powder for 10 minutes by means of pumping vacuum, mix the raw material powder and water evenly according to the mass ratio of 1:35, and pour it into the extraction tank;

[0030] (2) Biotransformation: add cinnamic acid, citric acid, benzoic acid (food grade, account for 0.3% of the white lemon powder quality, proportioning is 1:2:0.5) in the extraction tank, add compound biological agent (rhamnose Lactobacillus (L.rhamnosus), β-glucosidase, α-glucosidase, pectinase, limonin dehydrogenase, all food grade, enzyme activities are 3000u / g, 1000u / g, 10...

Embodiment 3

[0035] A preparation method and application of white lemon volatile oil, comprising the steps of:

[0036] (1) Raw material processing: After the white lemon fruit is cleaned, the peel and pulp are separated, the core is removed, the peel and the pulp residue after squeezing the lemon juice are air-dried, and they are put into a low-temperature pulverizer together at 1° C. to be pulverized into 200-mesh powder. Sieve, vacuumize the raw material powder for 5 minutes by pumping it to vacuum, mix the raw material powder and water evenly according to the mass ratio of 1:10, and pour it into the extraction tank;

[0037](2) biotransformation: add cinnamic acid, caffeic acid, citrate, benzoic acid (food grade, account for 0.5% of the white lemon powder quality in the extraction tank, the proportioning between is mass ratio 1:0.6:0.4:1.2 ), adding compound biological preparations (Lactobacillus rhamnosus (L.rhamnosus), β-glucosidase, α-glucosidase, pectinase, limonin dehydrogenase, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com