Method for preparing tendon composite muscle decellularized material derived from natural tissue

A decellularization and tendon technology, used in tissue regeneration, medical science, prosthesis, etc., can solve the problems of rupture, complex junction, poor mechanical properties of muscle scaffolds, etc., to achieve strong biomechanical properties, low immune rejection, good The effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

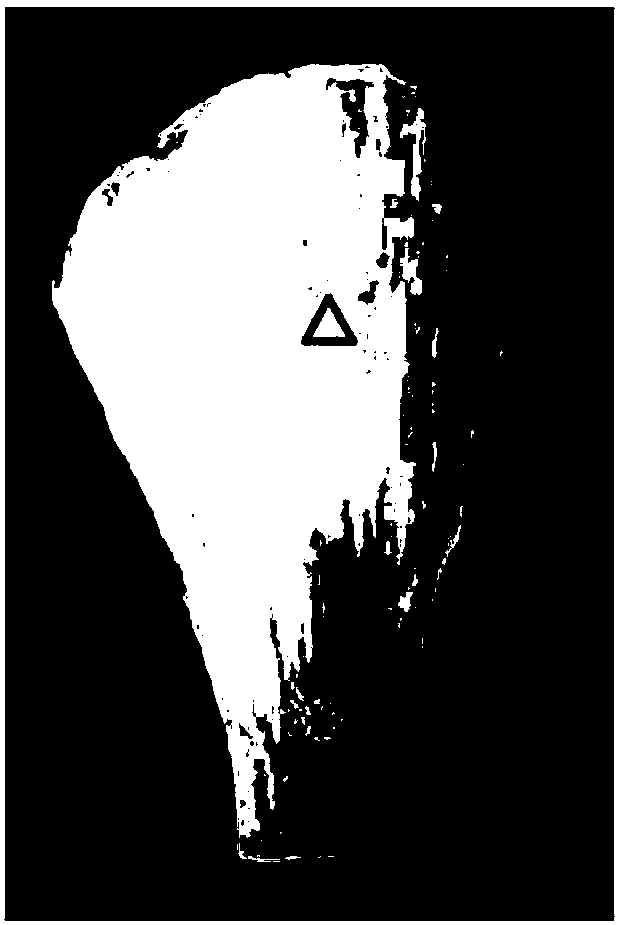

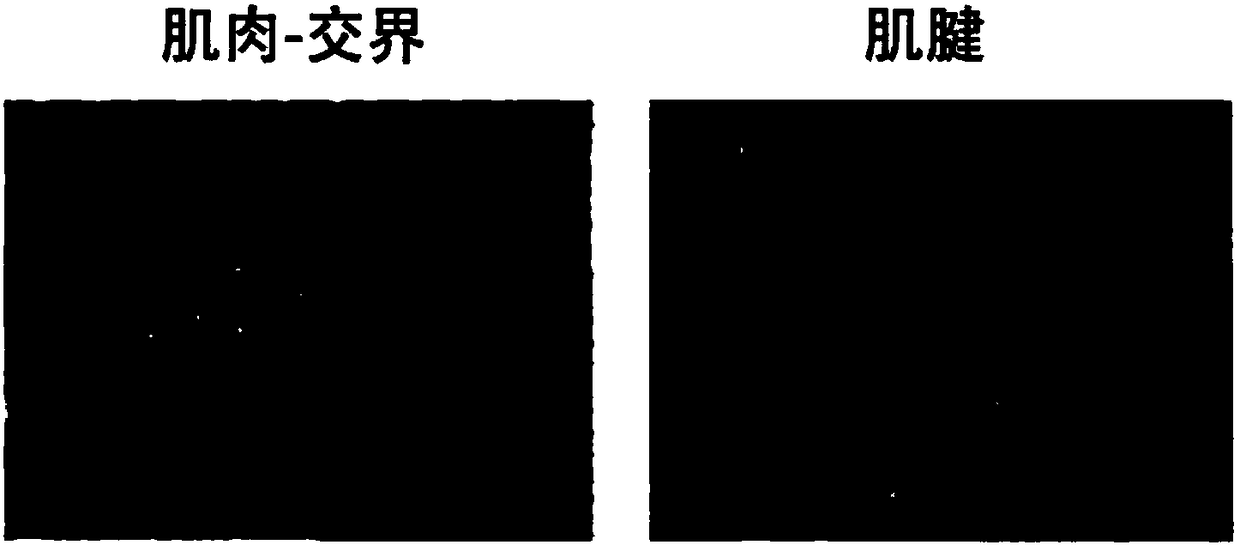

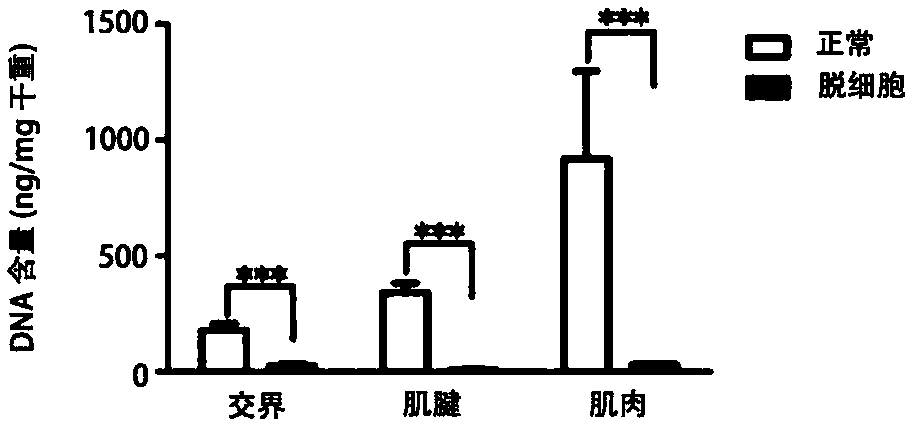

[0040] Example 1: Preparation method and regenerative repair research of tendon composite muscle decellularized material derived from natural tissue

[0041] 1. Preparation of Tendon Composite Muscle Decellularized Material

[0042] (1) Materials: Take the tendon compound muscle material from the Achilles tendon of pigs, cut the tendon into length, width and thickness of 2*1.0*0.2cm according to the fiber direction, and the length, width and height of the muscle are 0.3cm. IU / ml protease inhibitor normal saline rinsed 3 times, 30min each time, fully rinsed with sterile PBS to remove blood and other impurities.

[0043] (2) The decellularization steps are as follows:

[0044] ①. In the PBS buffer solution containing 10K IU / ml protease inhibitor, shake at 100 rpm on a low temperature (4°C) shaker for 48 hours, and then freeze and thaw with liquid nitrogen for 3 cycles (-80°C / 37°C);

[0045] ②. In the PBS buffer containing 0.1M KCL, add penicillin and streptomycin (20KIU / ml, 20...

Embodiment 2

[0061] Example 2: Preparation and regenerative repair of decellularized tendon and muscle materials

[0062] 1. Preparation of Tendon Composite Muscle Decellularized Material

[0063] (1) Materials: Take the tendon compound muscle material from the Achilles tendon of pigs, cut the tendon into length, width and thickness of 4.0*2.0*0.4cm according to the fiber direction, and the length, width and height of the muscle are 0.6cm. IU / ml protease inhibitor normal saline rinsed 3 times, 30min each time, fully rinsed with sterile PBS to remove blood and other impurities.

[0064] (2) The decellularization steps are as follows:

[0065] ①. In the PBS buffer solution containing 30K IU / ml protease inhibitor, shake at 100 rpm for 48 hours on a low-temperature (4°C) shaker, and then freeze and thaw with liquid nitrogen for 3 cycles (-80°C / 37°C);

[0066] ②. In the PBS buffer containing 0.5M KCL, add penicillin and streptomycin (20KIU / ml, 20g / ml) mixed antibacterial solution 1:1, and sha...

Embodiment 3

[0071] Example 3: Preparation method and regenerative repair research of tendon composite muscle decellularized material derived from natural tissue

[0072] 1. Preparation of Tendon Composite Muscle Decellularized Material

[0073] (1) Materials: The tendon compound muscle material was taken from the Achilles tendon of sheep, and the tendon was cut into length, width and thickness according to the fiber direction of 4.0*2.0*0.6cm, and the length, width and height of the muscle were 0.6cm. IU / ml protease inhibitor normal saline rinsed 3 times, 30min each time, fully rinsed with sterile PBS to remove blood and other impurities.

[0074] (2) The decellularization steps are as follows:

[0075] ①. In the PBS buffer solution containing 30K IU / ml protease inhibitor, shake at 100 rpm for 36 hours on a low-temperature (4°C) shaker, and then freeze and thaw with liquid nitrogen for 3 cycles (-80°C / 37°C);

[0076] ②. In the PBS buffer containing 0.5M KCL, add penicillin and streptomy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com