Preparation method and application for ternary composite photocatalyst

A ternary composite, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve problems such as low photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The preparation method of this ternary composite photocatalyst comprises the following steps:

[0061] Prepare g-C 3 N 4 catalyst of light:

[0062] Weigh 10g of urea into a crucible, cover the crucible, place it horizontally in a muffle furnace, and calcinate at 600°C for 4 hours. 3 N 4 sample.

Embodiment 2

[0064] The preparation method of this ternary composite photocatalyst comprises the following steps:

[0065] Preparation of single carbon spheres:

[0066] At room temperature, slowly add 4.0 g of ground dextrose monohydrate into 40 mL of ultrapure water, stir well, place it in a 50 mL stainless steel autoclave, heat to 180 ° C for 6 h; After washing with pure water and absolute ethanol for 6 times, vacuum drying at 60°C for 10 hours, the carbon sphere material with uniform size was obtained.

Embodiment 3

[0068] The preparation method of this ternary composite photocatalyst comprises the following steps:

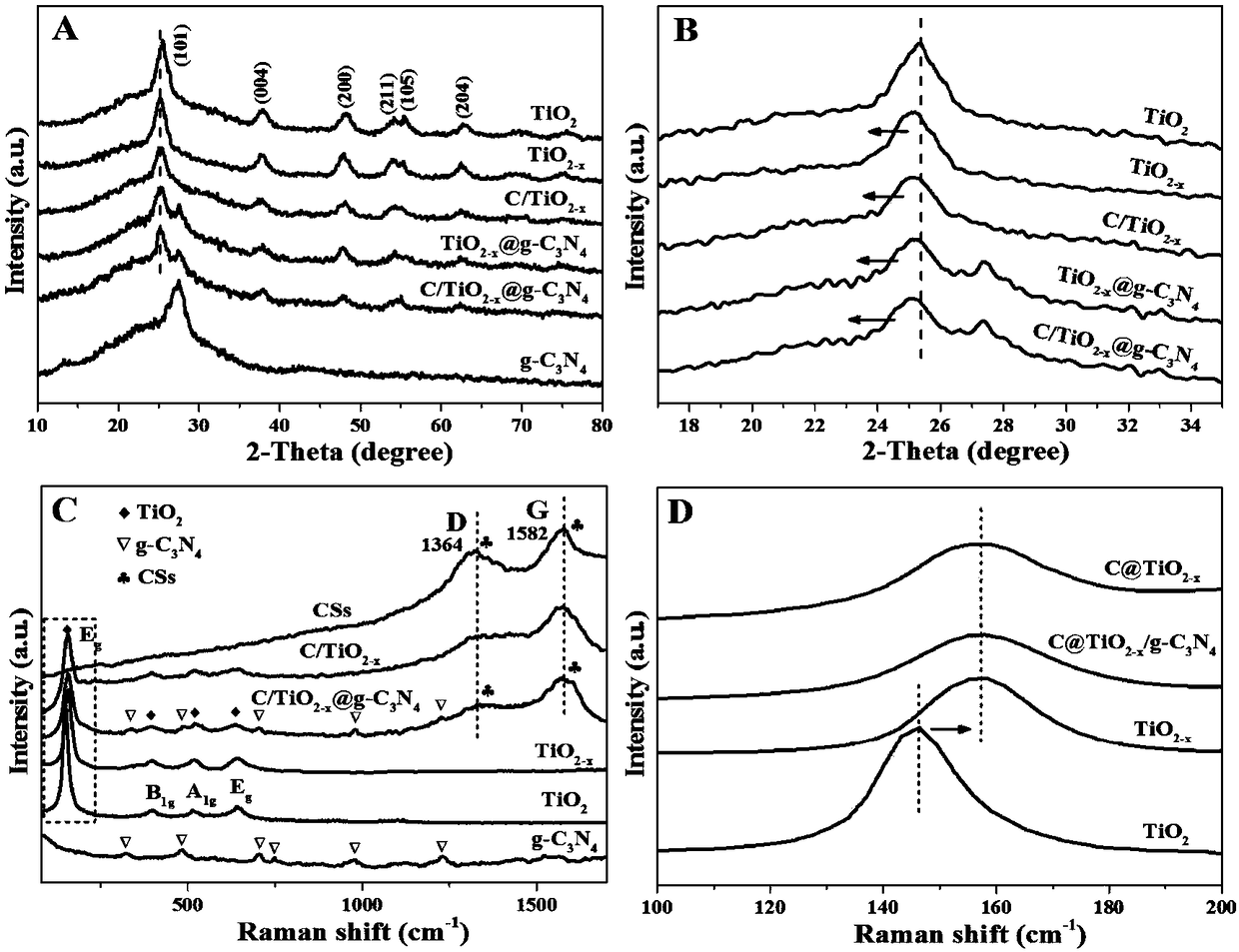

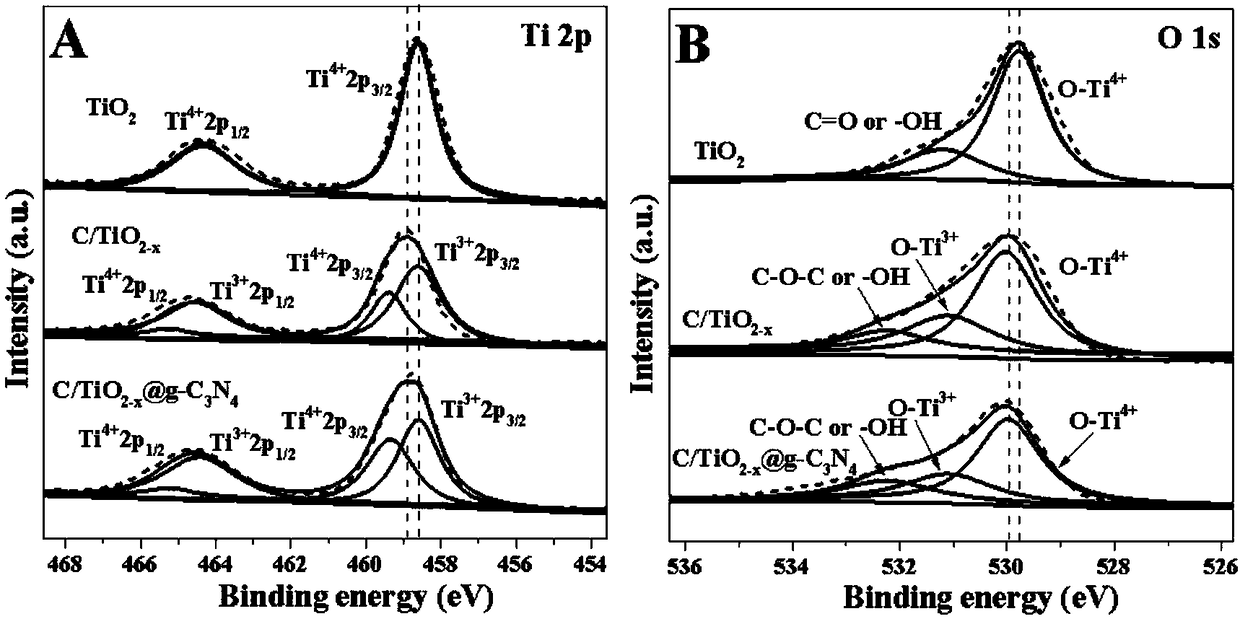

[0069] Preparation of C@TiO 2-x Composite material:

[0070] 1. Preparation of monomeric carbon spheres

[0071] 1. At room temperature, take 4.5g of glucose monohydrate and slowly add it to 45ml of pure water. After fully stirring, place it in a 50mL stainless steel autoclave and heat it to 180°C for 6 hours;

[0072] 2. After the reaction, wash with ultra-pure water and absolute ethanol for 6 times, and vacuum-dry at 60°C for 10 hours to obtain carbon sphere materials with uniform size.

[0073] 2. Preparation of C@TiO 2-x composite material

[0074] 1. Take 0.2g of carbon spheres and add them to a mixed solution of 35mL of absolute ethanol and 0.1mL of ultrapure water, and sonicate for 0.5h to obtain dispersion A;

[0075] 2. Take 2mL of tetrabutyl titanate and slowly add it into 40mL of absolute ethanol, stir and mix well to obtain dispersion B;

[0076] 3. Slowly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com