Method for preparing high-viscosity dicyandiamide-formaldehyde condensation polymer through aluminum sulfate catalysis and application of high-viscosity dicyandiamide-formaldehyde condensation polymer

A formaldehyde polycondensate, catalytic preparation technology, applied in chemical instruments and methods, water pollutants, textile industry wastewater treatment and other directions, can solve the problems of low solid content, limited wide use, high cost, wide pH applicable range, decolorization Good effect, less dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

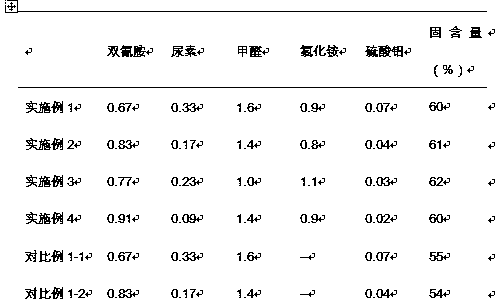

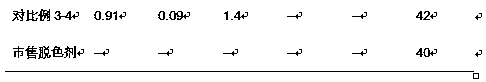

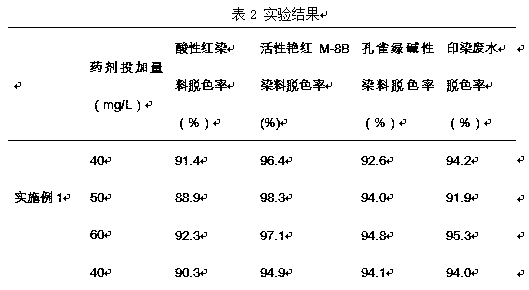

Embodiment 1

[0021] Add 28.77g of dicyandiamide, 10.26g urea, 24.73g ammonium chloride and 44ml formaldehyde solution in a four-necked flask with stirring, condensing reflux tube and thermometer, then fully mix the above-mentioned ingredients and heat slowly, react 10 After ~15 minutes, the reaction system is exothermic, stop heating, the temperature of the mixing system is automatically raised to 35~45°C, then add 12g of aluminum sulfate, keep the temperature at 35~45°C for 20 minutes, then add 23ml of formaldehyde solution, heat up After reacting for 3 hours at 75°C, the temperature was slowly lowered to room temperature. The obtained high-viscosity dicyandiamide-formaldehyde condensation polymer is a colorless transparent viscous solid.

Embodiment 2

[0023] Add 30.53g of dicyandiamide, 4.47g of urea, 18.72g of ammonium chloride and 30ml of formaldehyde solution in a four-neck flask with stirring, condensing reflux tube and thermometer, then fully mix the above-mentioned ingredients and heat slowly, react 10 After ~15 minutes, the reaction system is exothermic, stop heating, the temperature of the mixing system is automatically raised to 35~45°C, then add 6g of aluminum sulfate, keep the temperature at 35~45°C for 20 minutes, then add 20ml of formaldehyde solution, heat up After reacting for 3 hours at 70°C, the temperature was slowly lowered to room temperature. The obtained high-viscosity dicyandiamide-formaldehyde condensation polymer is a colorless transparent viscous solid.

Embodiment 3

[0025] Add 25.22g of dicyandiamide, 5.39g of urea, 22.95g of ammonium chloride and 20ml of formaldehyde solution in a four-necked flask with stirring, condensing reflux tube and thermometer, then fully mix the above-mentioned ingredients and heat slowly, react 10 After ~15 minutes, the reaction system is exothermic, stop heating, the temperature of the mixing system is automatically raised to 35~45°C, then add 4g of aluminum sulfate, keep the temperature at 35~45°C for 20 minutes, then add 20ml of formaldehyde solution, heat up to 65°C, reacted for 3 hours, and then slowly cooled down to room temperature. The obtained high-viscosity dicyandiamide-formaldehyde condensation polymer is a colorless transparent viscous solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com