UV-infrared double-wave band integrated p-i-n type photoelectric detector

A p-i-n, photodetector technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of complex optical system and device preparation process, increasing the difficulty of growing heterogeneous materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

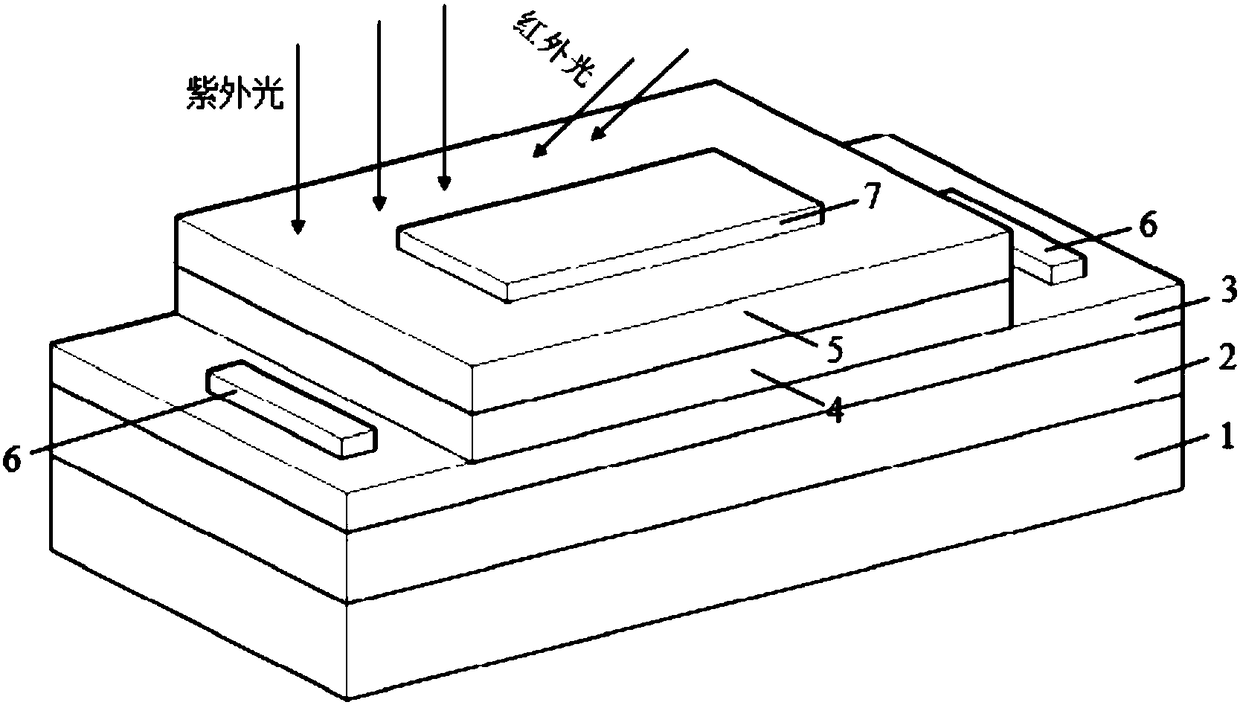

[0037] The fabrication method of the above-mentioned ultraviolet-infrared dual-band integrated p-i-n photodetector is as follows:

[0038] i) growing an AlN buffer layer 2 with a thickness of about 100 nm to 1 μm on the c-surface of the sapphire substrate by metal-organic vapor phase epitaxy;

[0039]ii) growing n-type ultra-short-period superlattice 3 , non-doped i-type ultra-short-period superlattice 4 , and p-type ultra-short-period superlattice 5 sequentially on the above-mentioned AlN buffer layer 2 . In the actual growth process, trimethylgallium (TMG) and trimethylaluminum (TMA) were used as group III sources, ammonia (NH 3 ) as the V group source, while using dipentyl magnesium (Cp 2 Mg) and silane (SiH 4 ) as p-type and n-type impurity sources, hydrogen (H 2 ) as the carrier gas.

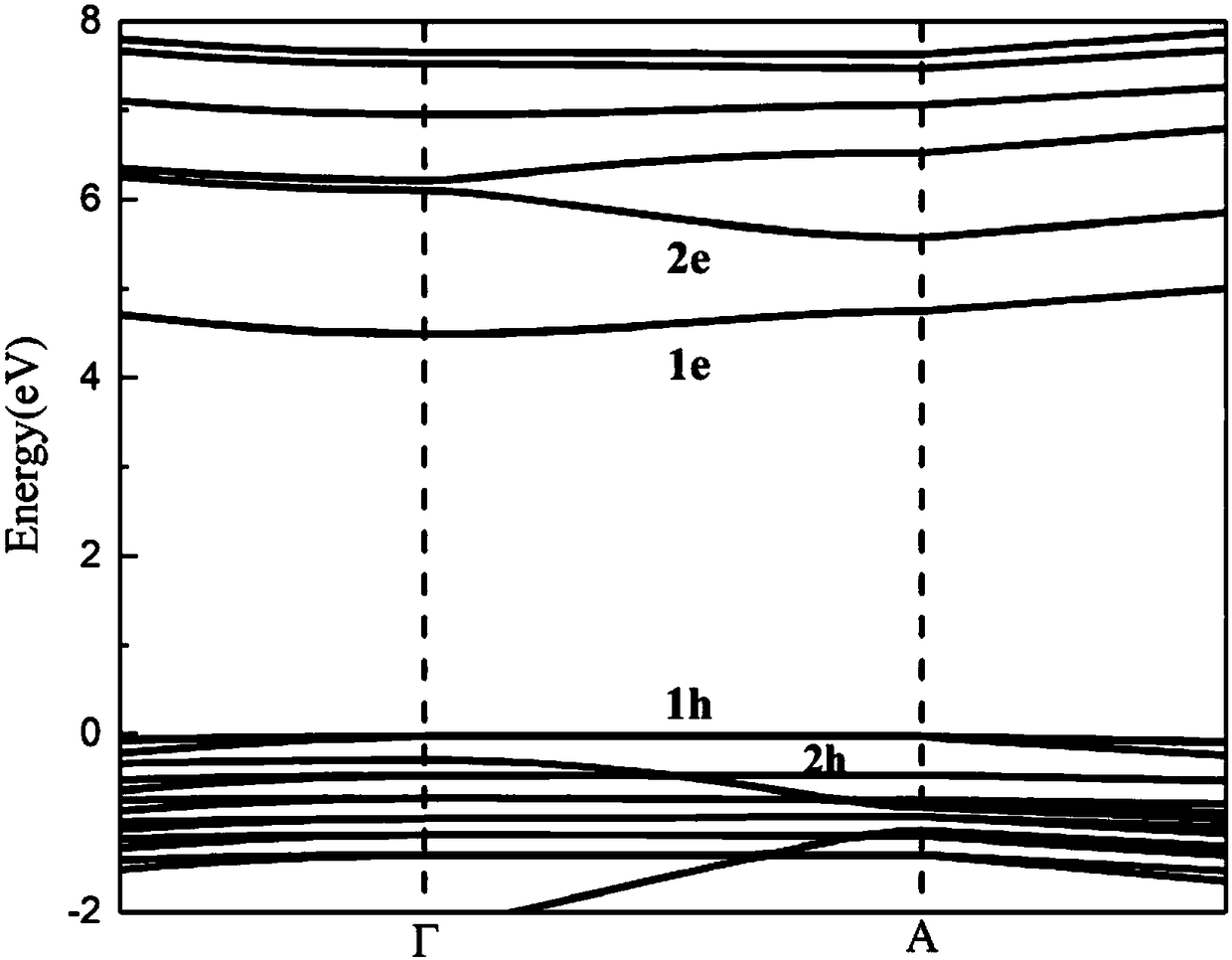

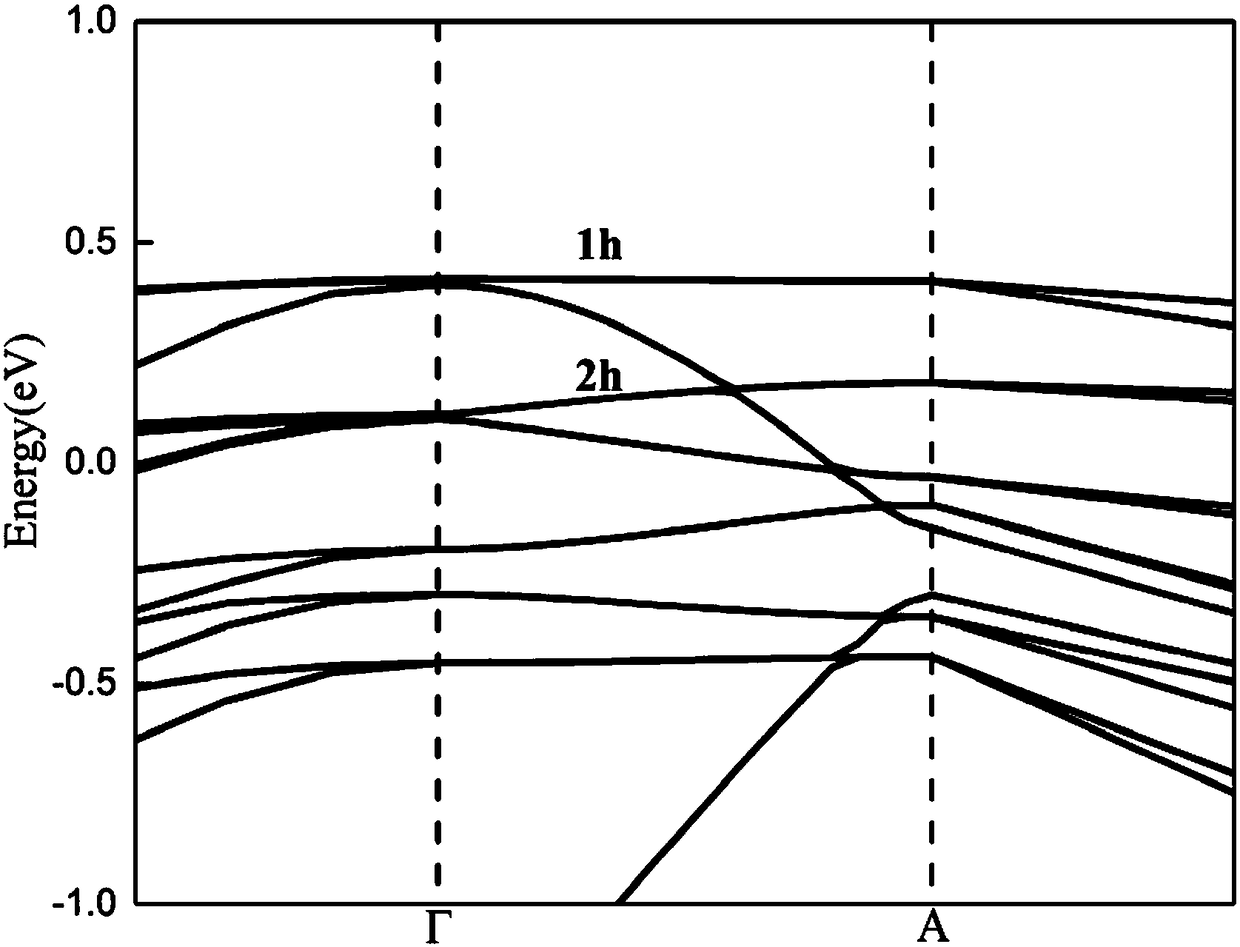

[0040] The non-doped i-type ultra-short-period superlattice 4 adopts a GaN / AlN ultra-short-period supercrystalline structure, and uses growth interruption technology to control the GaN ...

Embodiment 2

[0049] In this embodiment, the layered structure of the ultraviolet-infrared dual-band integrated p-i-n photodetector is the same as that of embodiment 1, and the specific manufacturing steps are as follows:

[0050] i) Using metal-organic vapor phase epitaxy, sequentially grow AlN buffer layer 2, n-type ultra-short period superlattice 3, non-doped i-type ultra-short period superlattice 4, p-type ultrashort period superlattice Periodic superlattice 5. The epitaxy steps are the same as those in Embodiment 1.

[0051] ii) Grinding the side of the above-mentioned complete p-i-n epitaxial structure facing the side of the substrate 1 and making it form an angle of 45°, so as to satisfy the polarization selection condition of the sub-band transition.

[0052] iii) Similarly, use standard photolithography, ICP etching and electron beam deposition and other micromachining processes to etch n-type mesas and deposit titanium / aluminum / titanium / gold alloys on them, and form n-type ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com