Method for preparing silicon-carbon negative electrode material based on micron silicon dioxide

A technology of silicon dioxide and negative electrode materials, which is applied in the direction of battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of high preparation cost, easy aggregation of particles, and difficulty in industrialization and application, and achieve simple operation and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

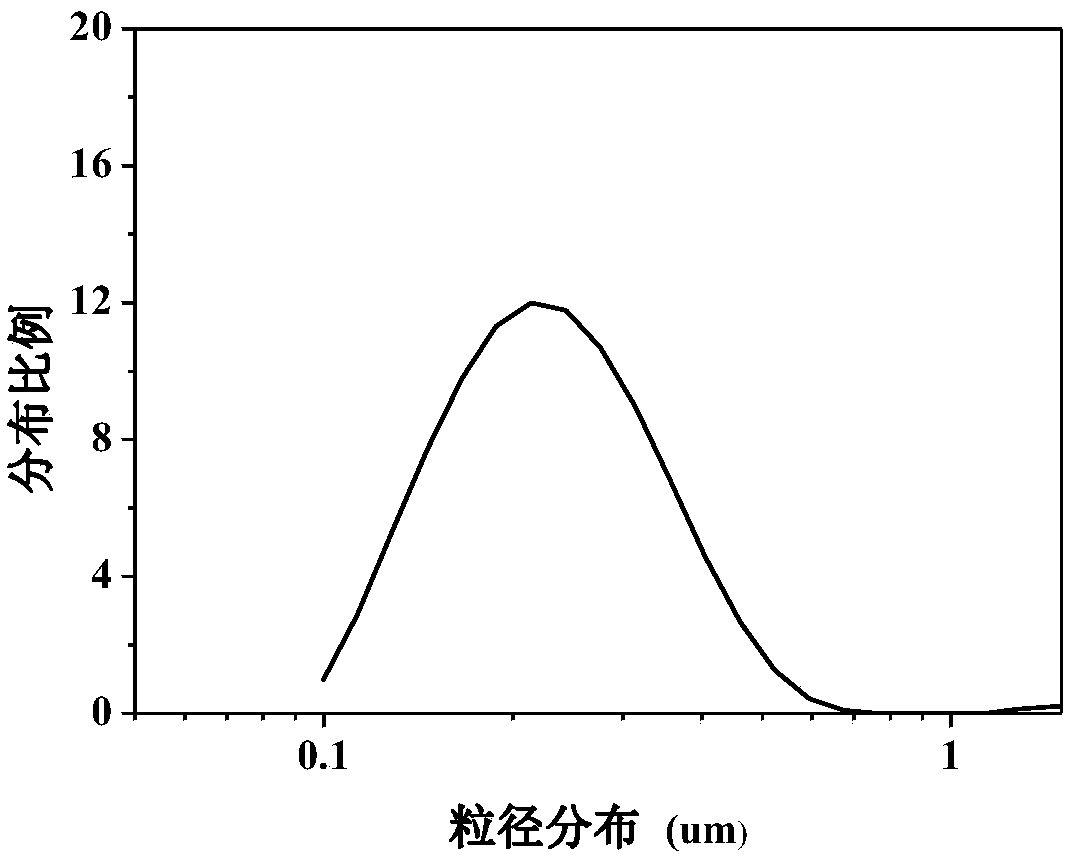

[0023] Weigh SiO 2 30g, 5g of polyvinylpyrrolidone and 120mL of water were placed in a sand mill, wet-milled for 4 hours, separated, placed in a refrigerator, and freeze-dried in a freeze dryer at -45°C for two days and two nights.

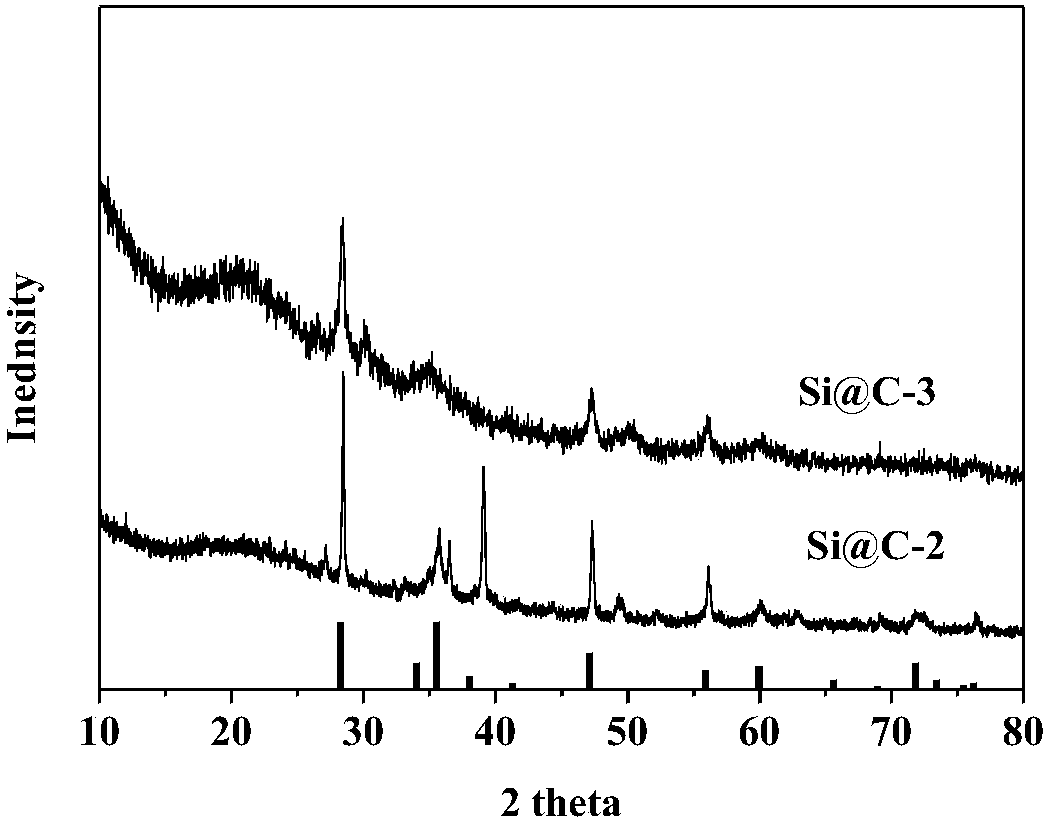

[0024] The freeze-dried product was placed in a tube furnace and calcined at 450 °C for 4 h in an inert atmosphere to obtain SiO 2 @C material, then follow SiO 2 The mass ratio of @C:Mg:NaCl is 1:1:1, in an inert atmosphere, magnesia thermal reduction at 650°C for 4 hours, washing in 2M hydrochloric acid solution for 8 hours, to remove magnesia reaction by-products; The solution after washing is added into a hydrofluoric acid solution with a mass fraction of 5% to wash for 0.5h to remove incompletely reacted SiO 2 , washed with deionized water and ethanol solution, filtered until neutral, placed in a vacuum oven, and dried in vacuum at 80°C for 12h to obtain a Si@C composite material.

[0025] The Si@C composite material and graphene oxide wer...

Embodiment 2

[0027] Weigh SiO 2 40g, 10g of polyvinylpyrrolidone and 120mL of water were mixed with a sand mill, wet-milled for 4 hours, separated, placed in a refrigerator, and freeze-dried in a freeze dryer at -45°C for two days and two nights.

[0028] The freeze-dried product was placed in a tube furnace and calcined at 450 °C for 4 h in an inert atmosphere to obtain SiO 2 @C material, then follow SiO 2 The mass ratio of @C:Mg:NaCl is 1:1:1, in an inert atmosphere, magnesia thermal reduction at 650°C for 4 hours, washing in 2M hydrochloric acid solution for 8 hours, to remove magnesia reaction by-products; The solution after washing is added into a hydrofluoric acid solution with a mass fraction of 5% to wash for 0.5h to remove incompletely reacted SiO 2 , washed with deionized water and ethanol solution, filtered until neutral, placed in a vacuum oven, and dried in vacuum at 80°C for 12h to obtain a Si@C composite material.

[0029] The Si@C composite material and graphene oxide w...

Embodiment 3

[0031] Weigh SiO 2 60g, 5g of polyvinylpyrrolidone and 120mL of water were mixed with a sand mill, wet-milled for 4 hours, separated, placed in a refrigerator, and freeze-dried in a freeze dryer at -45°C for two days and two nights.

[0032] The freeze-dried product was placed in a tube furnace and calcined at 500°C for 4 hours in an inert atmosphere to obtain SiO 2 @C material, then follow SiO 2 @C: The mass ratio of Mg:NaCl is 1:1:3, in an inert atmosphere, magnesia thermal reduction at 650°C for 4 hours, washing in 2M hydrochloric acid solution for 8 hours, to remove magnesia thermal reaction by-products; The solution after washing is added into a hydrofluoric acid solution with a mass fraction of 5% to wash for 0.5h to remove incompletely reacted SiO 2 , washed with deionized water and ethanol solution, filtered until neutral, placed in a vacuum oven, and dried in vacuum at 80°C for 12h to obtain a Si@C composite material.

[0033] The Si@C composite material and graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com