Method for preparing tea tree purple bud anthocyanin high-purity products through separation

An anthocyanin and purple bud technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems such as failure to make breakthrough progress and low content, and achieve low production cost and high yield. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

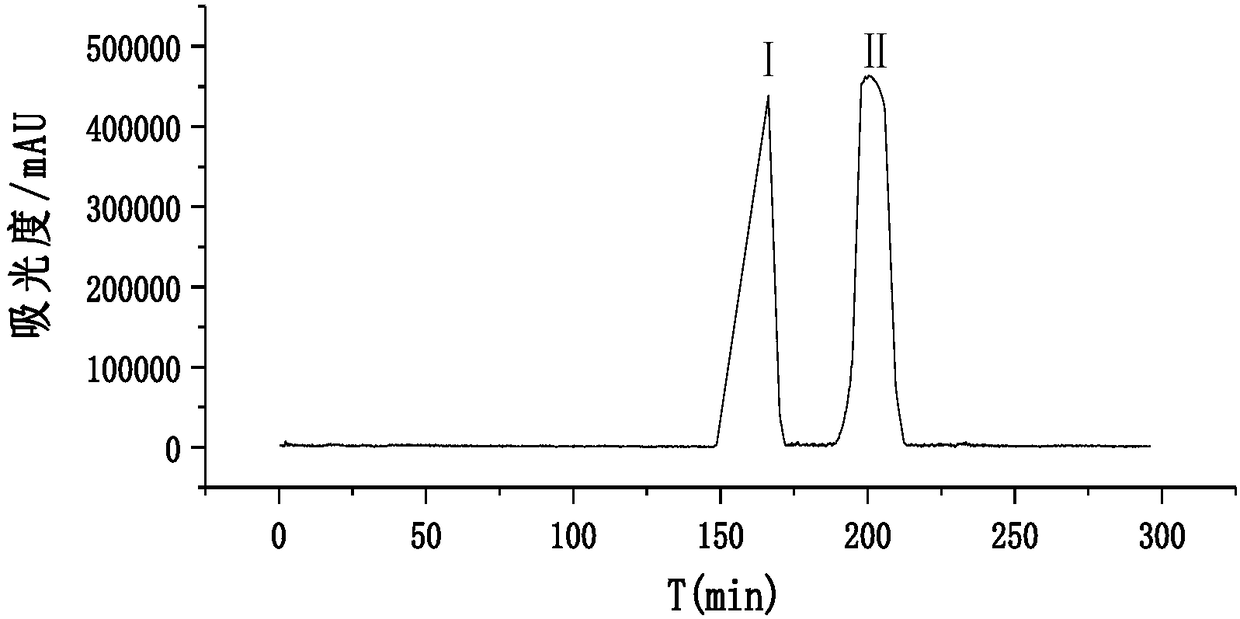

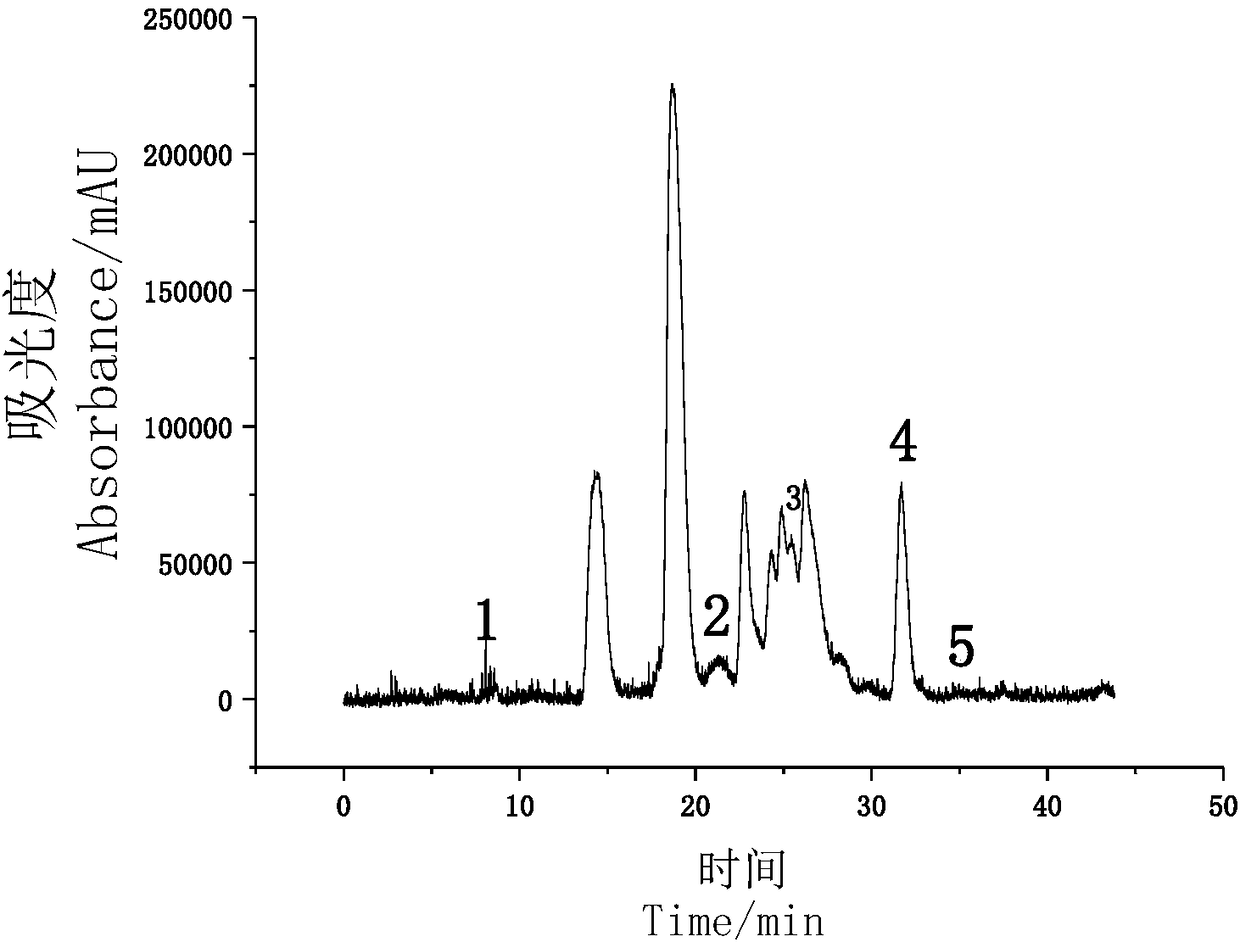

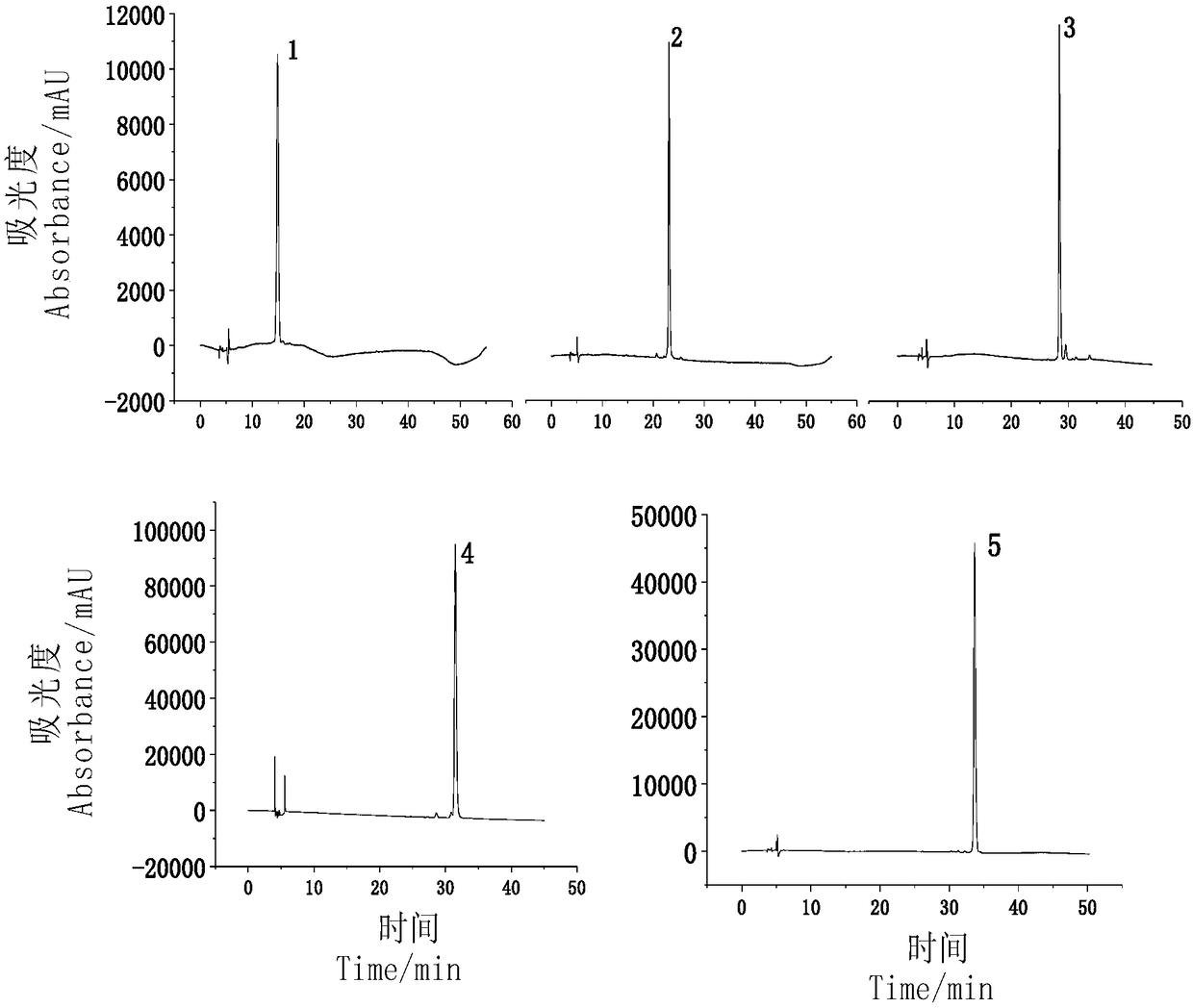

Embodiment 1

[0031] With one bud and two leaves of Zijuan tea tree as raw material, vacuum freeze-dry the tea leaves, grind them into powder, add 70% volume concentration ethanol solution containing 5% glacial acetic acid, stand at room temperature and avoid light for 3 (solid-liquid ratio is 1g:25ml, and each extraction time is 24h), obtains extract; Prepare n-hexane by volume ratio: ethyl acetate: the mixed solvent of water=1:1:1.5, use this mixed solvent to The extract is extracted and degreased; put the degreased extract on a sodium-type 732 cation exchange resin column, first adopt 90% volume concentration of ethanol solution to elute to remove polyphenol impurities, and then use 4% HCI-ethanol solution to carry out gradient washing (The ethanol volume concentration of gradient elution is 50%, 60%, 70%, 80%, 90%), collect the eluate according to the concentration gradient, combine the eluate, and concentrate at -0.05MPa, 45°C to remove The organic phase was passed through D101 macropo...

Embodiment 2

[0033] Using purple bud tea tree optional 9803 with one bud and two leaves as raw material, the tea leaves are vacuum freeze-dried, ground into powder, and extracted with 80% ethanol solution containing 1% glacial acetic acid at room temperature and protected from light 3 times (the ratio of solid to liquid is 1g:22ml, and the extraction time is 20h each time), the extract is obtained; prepare n-hexane by volume ratio: ethyl acetate: a mixed solvent of water=1.2:1.2:1.8, and use the mixed solvent Extract and degrease the extract; put the degreased extract on a sodium-type 732 cation exchange resin column, first use 90% ethanol solution to elute to remove polyphenol impurities; then use 4% HCI-ethanol solution for gradient elution (The ethanol volume concentration of gradient elution is 50%, 60%, 70%, 80%, 90%), respectively collect eluate according to concentration gradient, combine eluate, concentrate at -0.07MPa, 42 ℃ to remove organic matter Phase, pass through D101 macropo...

Embodiment 3

[0035] Using purple bud tea tree, red bud bergamot, one bud and two leaves as raw materials, vacuum freeze-dry the tea leaves, grind them into powder, add 90% volume concentration of ethanol solution containing 10% volume fraction of glacial acetic acid, stand at room temperature and avoid light for extraction 2 times (the ratio of solid to liquid is 1g:25ml, and the extraction time is 12h each time), the extract is obtained; prepare n-hexane by volume ratio: ethyl acetate: water=1.5:1.5:2 mixed solvent, with the mixed solvent Extract and degrease the extract; put the degreased extract on a sodium-type 732 cation exchange resin column, first use ethanol solution with a volume concentration of 90% to remove polyphenol impurities; then use 4% HCI-ethanol solution for gradient Elution (volume concentration of ethanol for gradient elution is 50%, 60%, 70%, 80%, 90%), collect the eluate according to the concentration gradient, combine the eluate, concentrate at -0.07MPa, 38°C Remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com