A purification method for heavy metal ions in water polluted by underground coal gasification

A heavy metal ion and underground gasification technology, which is applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., to achieve the effects of convenient combination, avoiding secondary pollution, and remarkable removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

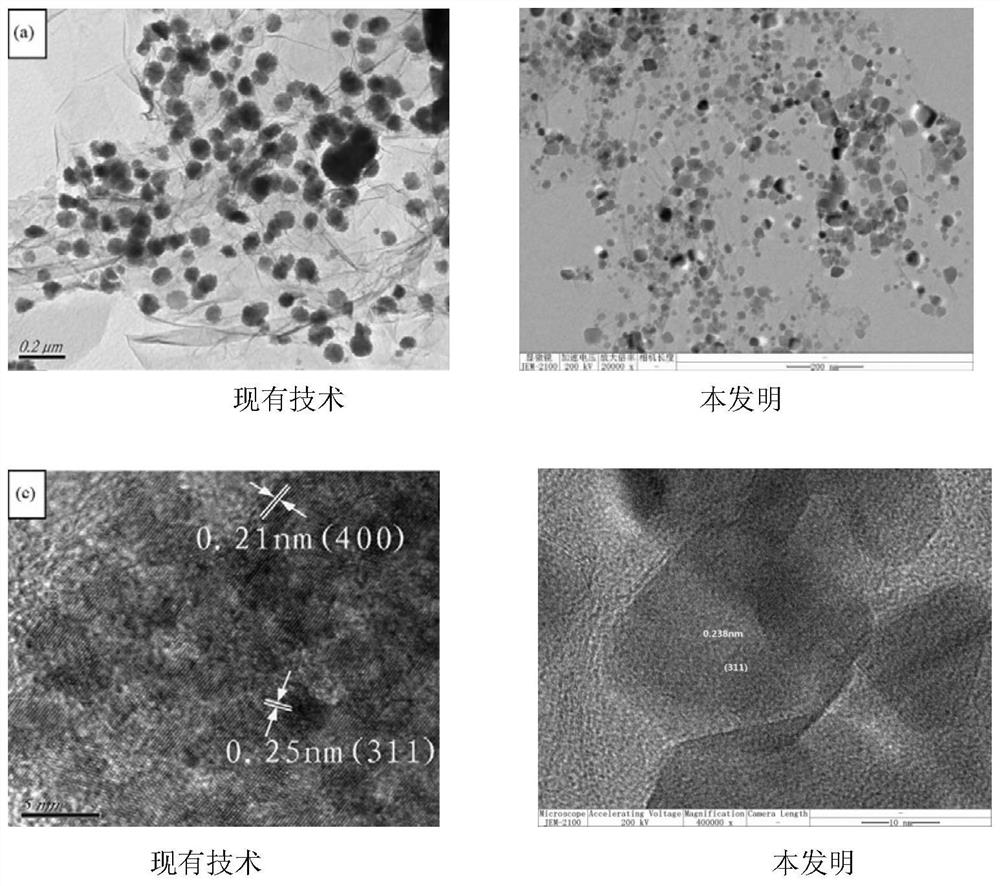

[0038] (1) Preparation of magnetic graphene composites

[0039]In the present embodiment, a one-step hydrothermal method is used to synthesize the magnetic graphene composite material, and the specific steps are as follows: 1.5 g of ferric chloride hexahydrate is completely dissolved in 20 mL of ethylene glycol to obtain a mixed solution A; the graphene oxide is suspended solution (30g, 1wt.%) was added to 130mL of ethylene glycol solution, ultrasonically dispersed into a uniform mixed solution B; the mixed solution A was added dropwise to the mixed solution B at a uniform speed, and 9.0g of sodium acetate was added under vigorous stirring. 30 mL ethylenediamine. Then the mixture was transferred to a polytetrafluoroethylene-lined stainless steel reactor and reacted at 180 °C for 8 h. After natural cooling to room temperature, the ethanol was washed several times, and the product was dried in a vacuum oven at 60°C to obtain a magnetic graphene composite.

[0040] Document 【On...

example 1

[0048] Table 1 Ion concentration and removal rate of underground coal gasification polluted water before and after purification

[0049]

[0050] Weigh 20 mg of magnetic graphene composite material and 100 mL of underground coal gasification polluted water for ultrasonic mixing, adjust the pH of the mixed solution to 2 with 0.5 mol / L HCl, stir and absorb for 75 minutes at 35 ° C to sample, and magnetically separate and recover the composite material The concentrations of various heavy metal ions in the samples were determined by graphite furnace atomic absorption spectrometry. The concentrations and removal rates of various heavy metal ions in the polluted water from underground coal gasification before and after purification by magnetic graphene composites are shown in Table 1.

[0051] It can be seen from the data in Table 1 that under the experimental conditions, the magnetic graphene composite material has an adsorption effect on various heavy metal ions in the undergro...

example 2

[0053] In order to further investigate the removal ability of the magnetic graphene composite material prepared by the present invention to heavy metal ions in underground coal gasification polluted water, the consumption of the composite material is increased from 20 mg per 100 mL to 50 mg, and the other conditions are kept the same. Inductively coupled plasma mass spectrometry was used to detect the polluted water before and after purification. The results are as follows: Figure 8 shown. It shows that the material has obvious removal effect on Cr, Mn, Ni, Zn, As, Cd and other heavy metal elements, and the removal rate is above 85%. Among them, the removal rates of Cr, Ni, As, and Cd are all close to 100%. It shows that the magnetic graphene composite material not only has a good removal effect on Cr(Ⅵ), but also has a good effect on the complex situation of the coexistence of various heavy metal ions such as Pb, Ni, Cu, Cr, Mn, Ni, Zn, As, and Cd. Excellent performance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com