Harmless integrated treatment method of oily sludge

A treatment method and sludge technology, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of polluted soil, water body and vegetation, difficulty in post-treatment system, waste of oil resources, etc. , to achieve the effect of saving energy, reducing secondary pollution of the environment, and running stable and low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

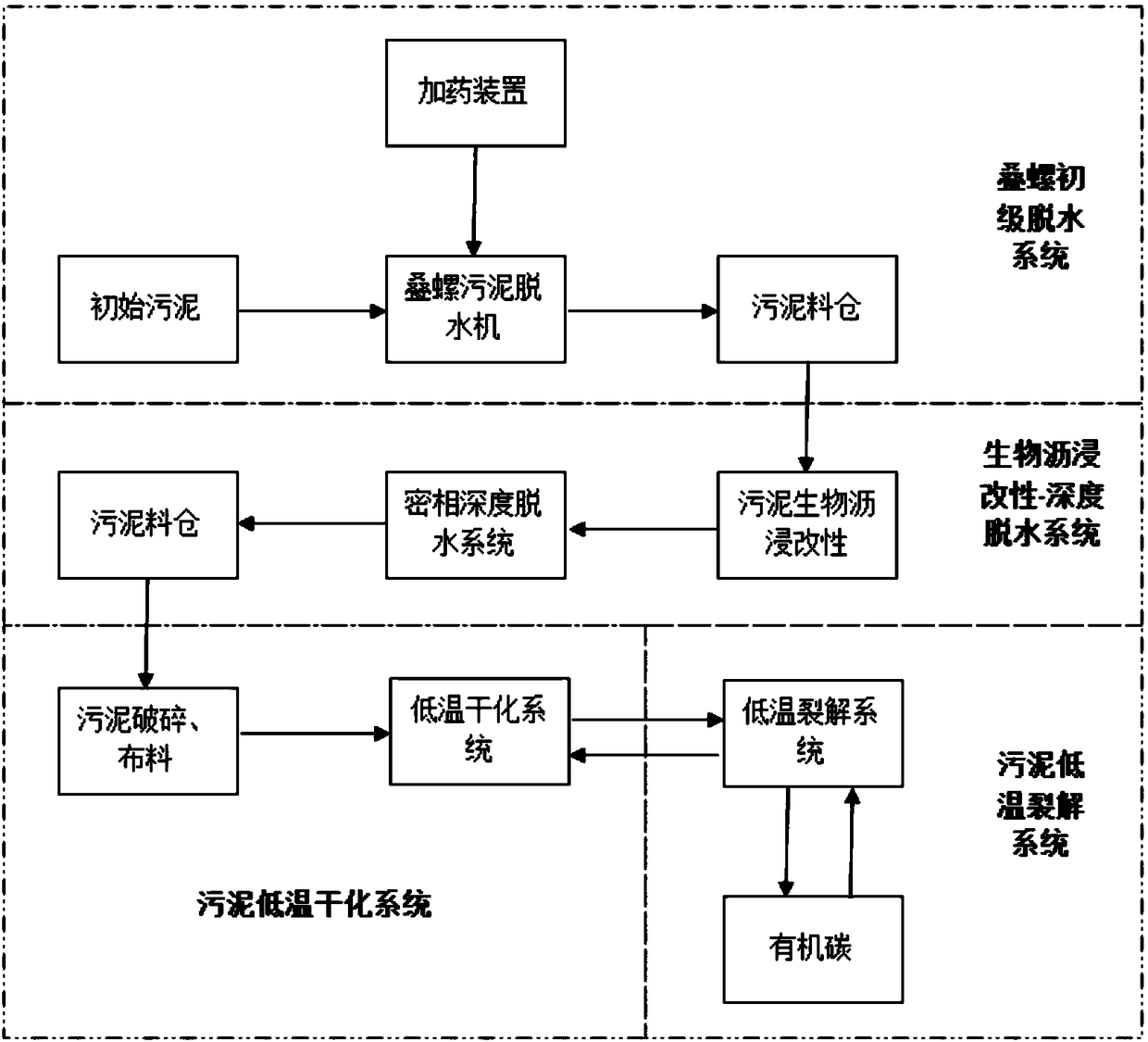

[0035] see figure 1 , a harmless integrated treatment method for oily sludge, comprising the following steps:

[0036] (1) Primary dehydration:

[0037] The sludge with a water content of 97-98% in the sludge thickening tank is lifted into the screw stack sludge dehydrator through a pump, and a flocculant accounting for 3-5% of the total weight of the sludge is added to the sludge. The composition is as follows: 25 parts by weight of sodium carbonate, 11 parts by weight of sodium metaaluminate, 8 parts by weight of NOC-1 flocculant, and 30 parts by weight of aluminum sulfate. The flocculant is composed of inorganic flocculant and microbial flocculant. The microbial flocculant has strong flocculation activity and can be used for the treatment of expanded sludge. It is easy to use and has little secondary pollution. The composite flocculant makes the sludge form large particle flocs, and under the action of mechanical extrusion, most of the free water and adsorbed water are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com