Multi-layer diaphragm material of lithium ion battery and preparation method thereof

A technology of multi-layer film and hybrid material, applied in the field of lithium-ion battery separator material and its preparation, can solve the problem of inability to exert the nano-performance of attapulgite, and achieve excellent thermal dimensional stability, improved liquid retention rate, and wide application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

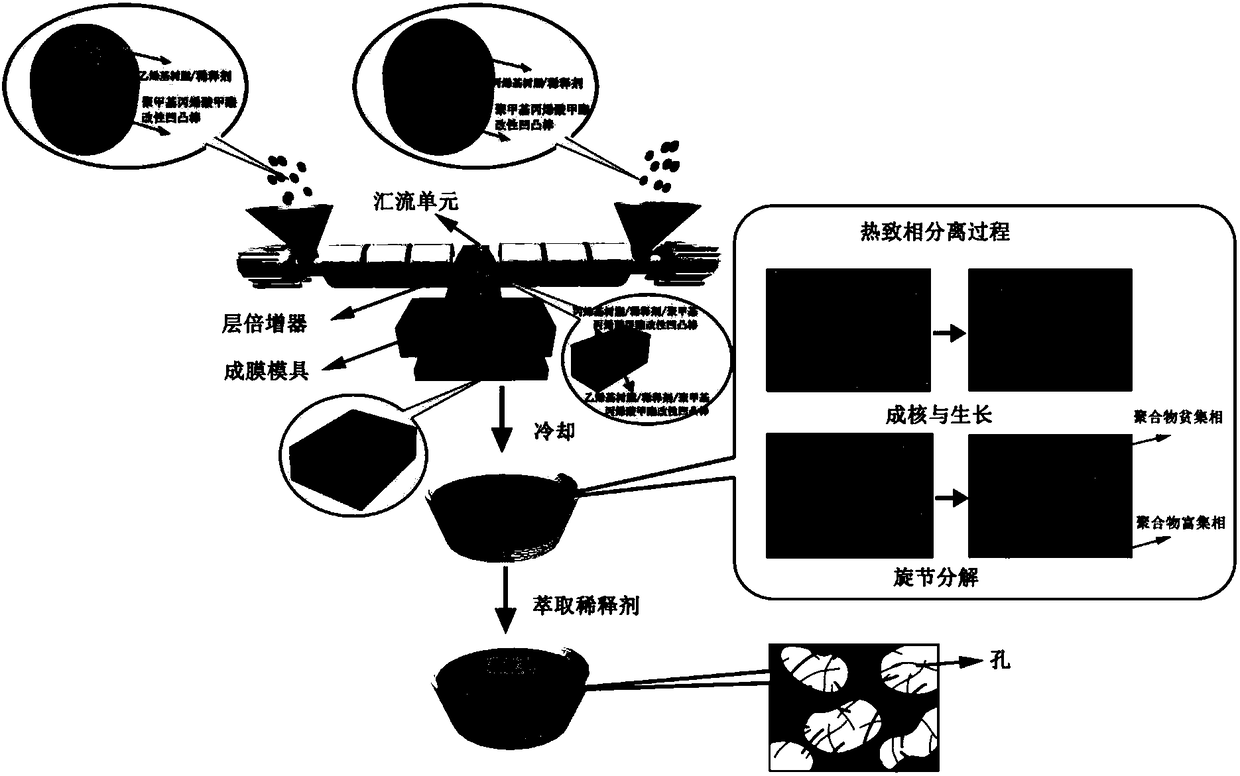

[0069] Example 1: Using solid paraffin as diluent and petroleum ether as extractant, microlayer co-extrusion technology and heat-induced phase separation method were used to prepare polyethylene / polypropylene multilayer porous diaphragm. Specific steps are as follows:

[0070] (1) Preparation of polyethylene / polypropylene masterbatch

[0071] Before micro-layer co-extrusion, the solid paraffin is pre-dispersed in polyethylene resin and polypropylene resin, and the above components are pre-mixed, and put into a twin-screw extruder to prepare a masterbatch of polyethylene resin and polypropylene resin .

[0072] The raw material composition of the masterbatch of polyethylene resin is calculated in parts by mass:

[0073] 45 parts of polyethylene resin,

[0074] 55 parts of solid paraffin.

[0075] The raw material composition of the masterbatch of polypropylene resin is calculated in parts by mass:

[0076] 45 parts of polypropylene resin,

[0077] 55 parts of solid paraff...

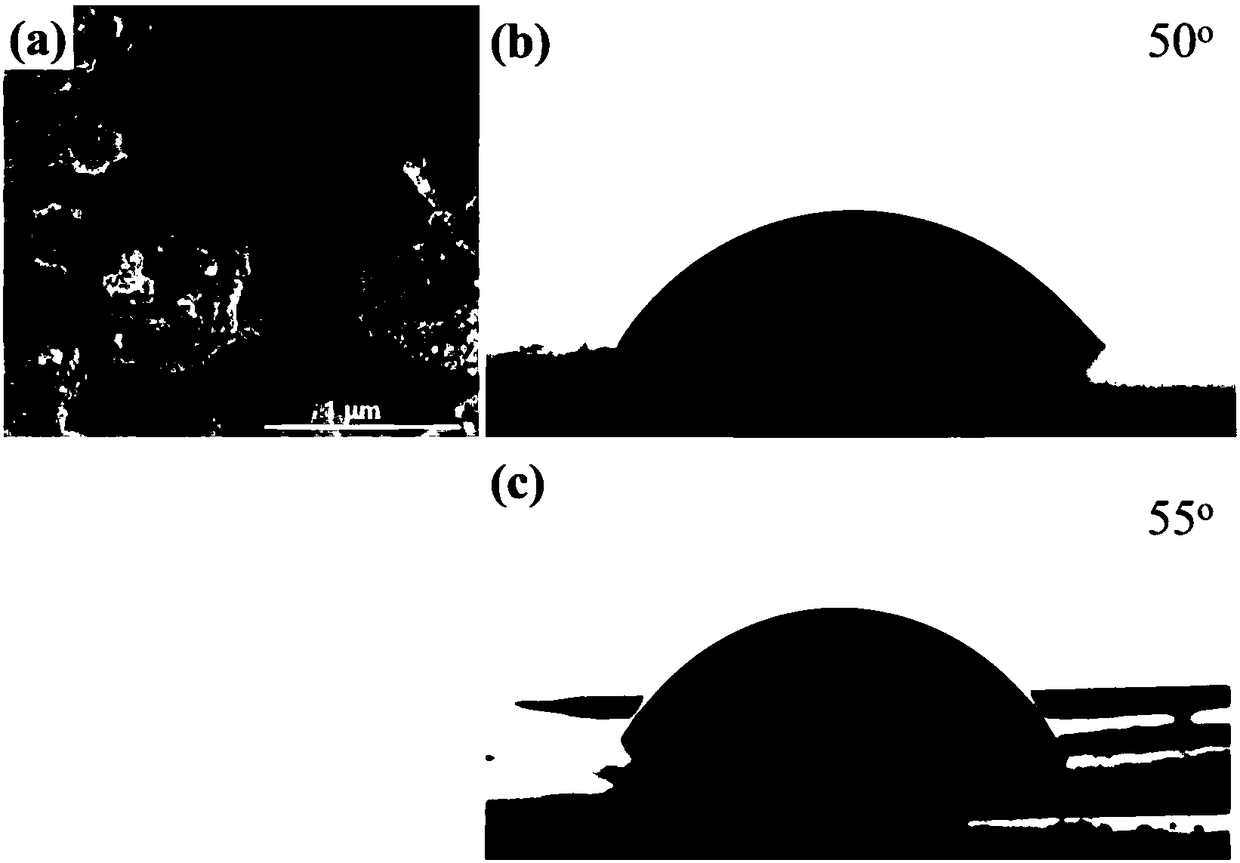

Embodiment 2

[0092] Example 2: Using solid paraffin as diluent and petroleum ether as extractant, polyethylene / polypropylene (6% polymethyl methacrylate modified attapulgite) was prepared by micro-layer co-extrusion technology and thermal phase separation method Layer porous membrane. Specific steps are as follows:

[0093] (1) Preparation of polymethyl methacrylate modified attapulgite

[0094] Attapulgite in 1 mol L -1Stir and react in hydrochloric acid for 3 h, then let stand for 12 h, filter and wash until neutral, dry and pulverize, weigh 1 part and disperse in xylene, vibrate ultrasonically for 1 h, add 1 part of 3-aminopropyl triethoxy base silane, heated to 80°C and stirred at constant temperature for 6 h, the product was filtered, washed and dried, crushed and passed through a 200-mesh sieve, and the product was designated as ATP-APTES. Weigh 1 part of ATP-APTES and disperse in ethyl acetate, and oscillate ultrasonically for 2 h; weigh 3 parts of azodicyanovaleric acid and diss...

Embodiment 3

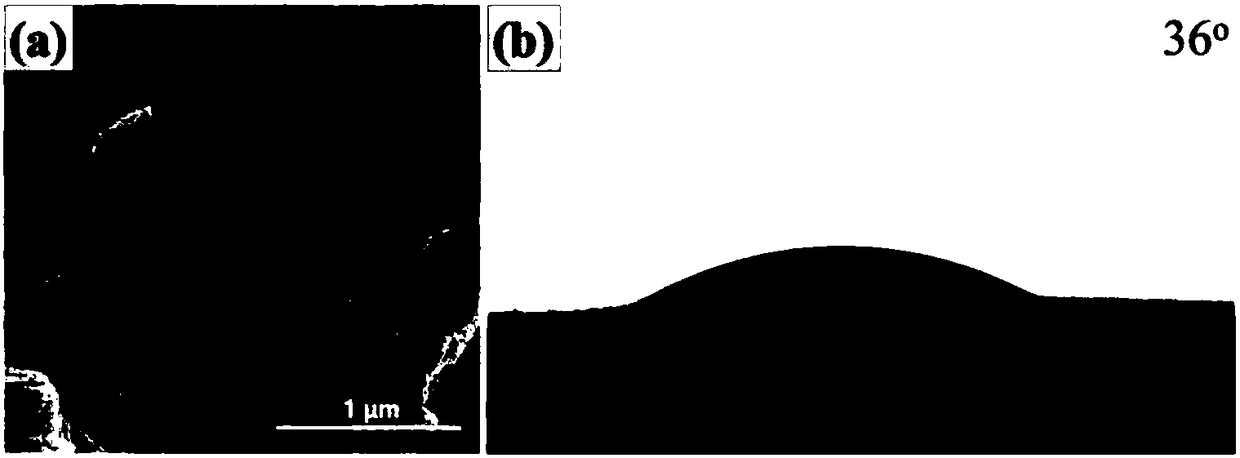

[0108] Example 3: Using solid paraffin as diluent and petroleum ether as extractant, polyethylene / polypropylene (9% polymethyl methacrylate modified attapulgite) was prepared by micro-layer co-extrusion technology and thermal phase separation method Layer porous membrane. Specific steps are as follows:

[0109] (1) Preparation of polymethyl methacrylate modified attapulgite

[0110] Attapulgite in 1 mol L -1 Stir in hydrochloric acid for 8 hours and let stand for 12 hours, filter and wash until neutral, dry and pulverize, weigh 2 parts and disperse in xylene, ultrasonically shake for 1 hour, add 2 parts of 3-aminopropyl triethoxy base silane, heated to 80°C and stirred at constant temperature for 6 h, the product was filtered, washed and dried, crushed and passed through a 200-mesh sieve, and the product was designated as ATP-APTES. Weigh 2 parts of ATP-APTES and disperse in ethyl acetate, and ultrasonically shake for 3 h; weigh 5 parts of azodicyanovaleric acid and dissolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com