A kind of inorganic polymer foam material prepared by utilizing sludge and its preparation method

A technology of inorganic polymers and foaming materials, applied in applications, ceramic products, household appliances, etc., can solve the problems of waste of resources, increase the cost of manpower and material resources, reduce the consumption of manpower and material resources, achieve great economic and environmental protection benefits, water absorption rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

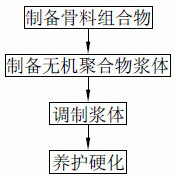

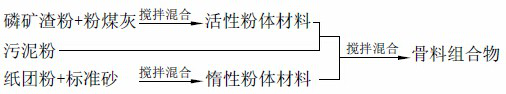

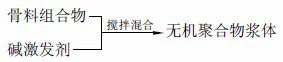

[0041] Such as Figure 1-3 As shown, a kind of inorganic polymer foaming material prepared by using sludge includes inorganic polymer slurry prepared by mixing an aggregate composition and an alkali activator, and the aggregate composition includes sludge powder and oxygen-containing The powder material of aluminum and / or silicon oxide, the sludge powder is obtained by drying the sludge. In this embodiment, the powder material is preferably prepared by mixing phosphate rock slag powder and fly ash. Active powder material, the particle size of the active powder material is less than 3mm, and in laboratory conditions, preferably the alkali activator is sodium hydroxide.

[0042] An inorganic polymer foam material prepared from sludge in this embodiment uses sludge produced by sewage treatment as one of the raw materials, which provides a better way for the sludge produced by sewage treatment and reduces the need for sludge treatment. The consumption of manpower and material res...

Embodiment 2

[0045] Such as Figure 1-3 As shown, a kind of inorganic polymer foaming material prepared from sludge in this embodiment has the same raw material components as in Example 1, the difference is that the powder material also includes fiber powder and / or standard sand. The inert powder material, the particle size of the inert powder material is less than 3mm, preferably the inert powder material in this embodiment is prepared by mixing standard sand and fiber powder made from waste paper, and the fiber powder It is made from waste paper through alkalization treatment, drying treatment, and crushing treatment in sequence. The fiber powder has several powder flocculations, and the fiber powder per unit volume includes 5%-30% of the volume percentage of powder flocculation. Each The diameter of the powder flocculation is less than 5mm.

[0046] An inorganic polymer foaming material prepared from sludge in this embodiment uses waste paper to prepare fiber powder, which provides a b...

Embodiment 3

[0049] Such as Figure 1-3 As shown, a kind of inorganic polymer foaming material prepared by using sludge in this embodiment, the raw material components are the same as in Example 2, the difference is that the weight ratio of each raw material in the inorganic polymer slurry is: sludge Powder: phosphate rock slag powder: fly ash is 1:1:1; the weight ratio of the sludge powder to standard sand is 1: (3-10); the weight ratio of the sludge powder to fiber powder is 1 : (2-3); the weight ratio of the sludge powder to the alkali activator is 1: (0.4-1); also includes the water used to reconcile the inorganic polymer slurry, the sludge powder and water The weight ratio is 1:(4.5-5).

[0050] In the raw material formula of an inorganic polymer foaming material prepared from sludge in this embodiment, the amount of each raw material component can be adjusted according to the actual situation to obtain inorganic polymer slurries with different gelling effects, and The sludge weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com