Environment-friendly type UV hand-brush filling and coloring coating and preparation method thereof

A pigmented paint, environmentally friendly technology, applied in polyester paint, polyurea/polyurethane paint, coatings, etc., can solve the problems of high VOC emission, poor paint film adhesion, low construction efficiency, etc., to improve construction efficiency, Good adhesion and no skin irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

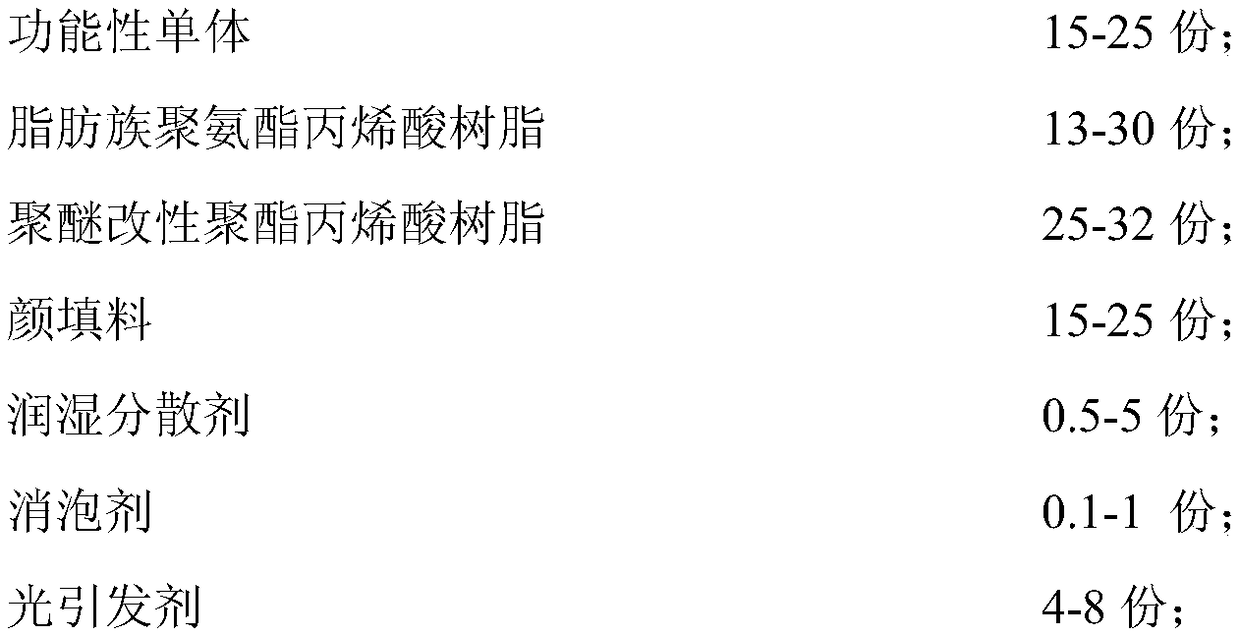

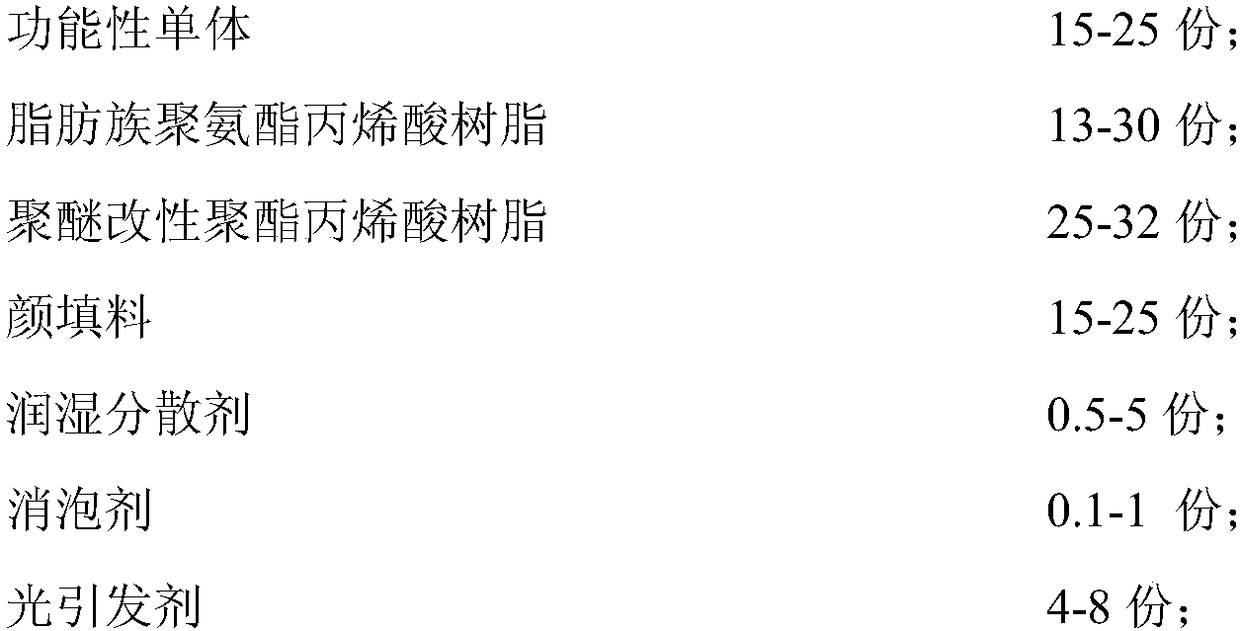

Method used

Image

Examples

Embodiment 1

[0020] The functional monomer is 15 kg of polyethylene glycol 400 diacrylate (PEG400DA), 13 kg of aliphatic urethane acrylic resin, 30 kg of polyether modified polyester acrylic resin, and the photoinitiator is trimethylbenzoyl- 0.5 kg of diphenylphosphine oxide, 0.1 kg of defoamer (TEGO920), 0.5 kg of wetting and dispersing agent, 15 kg of talcum powder, 1 kg of wax powder, 2 kg of fumed silica, mix and stir, after fully dispersed, add light Initiator 2-hydroxy-2-methyl-1-phenyl-1-propanone (1173) 5 kg, stir until fully dispersed and uniform without lumps. The experimental results of this example are: the viscosity of the product is basically moderate, the hardness of the paint film is moderate, the deep curing effect is achieved, and the wiping property is good.

Embodiment 2

[0022] Get 25 kg of functional monomer glycerol methoxy monoacrylate (TPGMEMA), 28 kg of aliphatic urethane acrylic resin, 32 kg of polyether modified polyester acrylic resin, photoinitiator phenyl bis(2,4 , 0.5 kg of 6-trimethylbenzoyl) phosphine oxide (819), 0.1 kg of defoamer, 1 kg of dispersant, 15 kg of talcum powder, 0.5 kg of wax powder, 1 kg of fumed silica, mixed and stirred, fully After dispersion, add 7 kg of photoinitiator phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide, stir well and disperse evenly without lumps. The experimental results of this example are: the viscosity of the product is basically moderate, the softness and hardness of the paint film are moderate, the deep layer curing achieves the effect, and the wiping property is good.

Embodiment 3

[0024] Take 15 kg of functional monomer polyethylene glycol 400 diacrylate (PEG400DA), 5 kg of glycerol methoxy monoacrylate (TPGMEMA), 20 kg of aliphatic urethane acrylic resin, polyether modified polyester acrylic acid 25 kg of resin, 0.5 kg of phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide (819), 0.1 kg of defoamer, 1 kg of dispersant, 15 kg of KB-121 talcum powder, wax powder 0.5 kg, 1 kg of fumed silica, mixed and stirred, after fully dispersed, add 5 kg of photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-acetone (1173), stir fully and disperse evenly without hard lumps Can. The experimental results of this example are: the viscosity of the product is basically moderate, the hardness of the paint film is moderate, the deep curing effect is achieved, and the wiping property is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com