Method for industrially producing carbon fluoride materials

A technology for producing fluorinated carbons and fluorinated carbons, applied in fluorinated carbons, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low fluorine content, easy explosion in production, uneven fluorination, etc., and achieve The effect of high reaction efficiency, high utilization rate and uniform product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

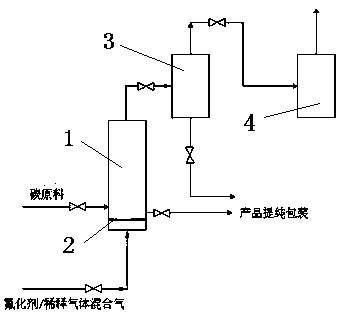

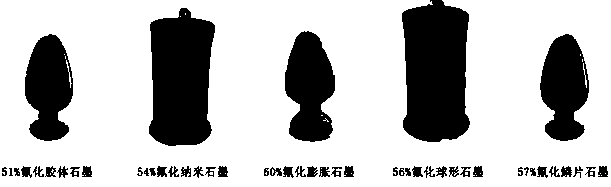

[0039] Taking the colloidal graphite raw material as an example, the method for producing fluorinated colloidal graphite using a fluidized bed reactor in a large-scale production of the present invention comprises the following steps:

[0040] Take 15 kg of colloidal graphite raw material and put it into the fluidized bed 1 containing the gas distribution plate 2, seal the whole system and pressurize the leak test, inject nitrogen gas to remove volatile impurities, and heat the fluidized bed 1 to raise the temperature; after 2 hours When the temperature reaches 250 °C, the mixed gas of oxygen difluoride / nitrogen is introduced from the bottom of the fluidized bed 1 at a flow rate of 7.5 Nm 3 / h; the pressure inside the fluidized bed 1 is normal pressure, the reaction temperature is 400~450°C, the concentration of oxygen difluoride is 4%, the reaction time is 38 h, stop heating, replace with nitrogen, and cool down naturally; wait for the fluidized bed 1 After the internal tempe...

Embodiment 2

[0043] Taking the nano-graphite raw material as an example, the production of fluorinated nano-graphite by using the method of the present invention for large-scale production of fluorinated carbon materials using a fluidized bed reactor includes the following steps:

[0044] Take 5 kg of nano-graphite raw material and put it into the fluidized bed 1 containing the gas distribution plate, seal the whole system and pressurize the leak test, inject helium gas to remove volatile impurities, and heat the fluidized bed 1; after 1 h When the temperature reaches 280 °C, the fluorine / helium gas mixture is introduced from the bottom of the fluidized bed 1 at a flow rate of 3.5 Nm 3 / h; the pressure inside fluidized bed 1 is normal pressure, the reaction temperature is 450~500 ℃, the concentration of fluorine gas is 3%, the reaction time is 42 h, stop heating, replace with helium, and cool down naturally; After the temperature dropped to room temperature, the material was taken out, and...

Embodiment 3

[0047] Taking the expanded graphite raw material as an example, the method for producing fluorinated expanded graphite using a fluidized bed reactor in a large-scale production of the present invention comprises the following steps:

[0048] Take 100 kg of expanded graphite raw material and put it into the fluidized bed 1 containing the gas distribution plate 2, seal the whole system and pressurize for leak testing, introduce carbon tetrafluoride to remove volatile impurities, and heat up the fluidized bed; 5 After 320 °C, nitrogen trifluoride / carbon tetrafluoride mixed gas was introduced from the bottom of the fluidized bed at a flow rate of 12 Nm 3 / h; the pressure inside the fluidized bed 1 is normal pressure, the reaction temperature is 460~510°C, the concentration of nitrogen trifluoride is 17%, the reaction time is 30 h, stop heating, replace with carbon tetrafluoride gas, and cool down naturally; After the internal temperature of the fluidized bed 1 was lowered to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com