Preparation method of water quality stabilizer

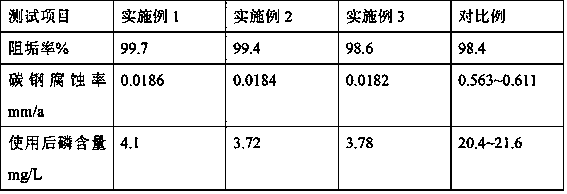

A technology of water quality stabilizer and mass ratio, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problem of excessive phosphorus content in circulating water sewage and eutrophication in circulating cooling water and other problems, to achieve the effects of fine grain size, enhanced adsorption capacity, and reduced phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A preparation method of a water quality stabilizer, comprising the steps of:

[0016] (1) Take pimelic acid and add thionyl chloride at a mass ratio of 2~4:5~7, heat up to 60~70°C, stir and mix for 1~2h, distill under reduced pressure to obtain a reduced pressure distillate, take the reduced pressure distillate according to Add bromine at a mass ratio of 1:1, stir and mix for 3~4 hours, heat up to 70~80°C for 2~3 hours, and let stand for 10~12 hours to obtain a standing liquid. In terms of parts by mass, take 20~30 parts of the standing liquid , 18~24 parts of diethyl phosphite, and 8~14 parts of pyridine were mixed, heated to 115~122°C and stirred and mixed for 3~4 hours to obtain a stirred mixture, distilled under reduced pressure, cooled to room temperature to obtain a cooled product;

[0017] (2) Take the cooling material and add hydrochloric acid with a mass fraction of 37% according to the mass ratio of 10:3, stir and mix at 75~80°C for 4~5h, distill under reduced...

Embodiment 1

[0021] A preparation method of a water quality stabilizer, comprising the steps of:

[0022] (1) Take pimelic acid and add thionyl chloride at a mass ratio of 2:5, heat up to 60°C, stir and mix for 1 hour, distill under reduced pressure to obtain a vacuum distillate, take the vacuum distillate and add bromine at a mass ratio of 1:1, Stir and mix for 3 hours, heat up to 70°C for 2 hours, and stand still for 10 hours to obtain a standing liquid. In terms of parts by mass, take 20 parts of standing liquid, 18 parts of diethyl phosphite, and 8 parts of pyridine to mix, and heat up to 115°C Stir and mix for 3 hours to obtain a stirred mixture, distill under reduced pressure, and cool to room temperature to obtain a cooled product;

[0023] (2) Take the cooling material and add hydrochloric acid with a mass fraction of 37% according to the mass ratio of 10:3, stir and mix at 75°C for 4h, distill under reduced pressure, then keep warm at 40°C for 3h, rotary evaporate, and concentrate...

Embodiment 2

[0027] A preparation method of a water quality stabilizer, comprising the steps of:

[0028] (1) Take pimelic acid and add thionyl chloride at a mass ratio of 4:7, heat up to 70°C, stir and mix for 2 hours, distill under reduced pressure to obtain a vacuum distillate, take the vacuum distillate and add bromine at a mass ratio of 1:1, Stir and mix for 4 hours, heat up to 80°C for 3 hours, and stand for 12 hours to obtain a standing liquid. In terms of parts by mass, take 30 parts of standing liquid, 24 parts of diethyl phosphite, and 14 parts of pyridine to mix, and heat up to 122°C Stir and mix for 4 hours to obtain a stirred mixture, distill under reduced pressure, and cool to room temperature to obtain a cooled product;

[0029] (2) Take the cooling material and add hydrochloric acid with a mass fraction of 37% according to the mass ratio of 10:3, stir and mix at 80°C for 5h, distill under reduced pressure, then keep warm at 50°C for 4h, rotary evaporate, concentrate to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com