Method and system for treating drilling mud

A technology of drilling mud and treatment method, which is applied in the fields of sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of leakage pollution, unrealized safe disposal of hazardous solid waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

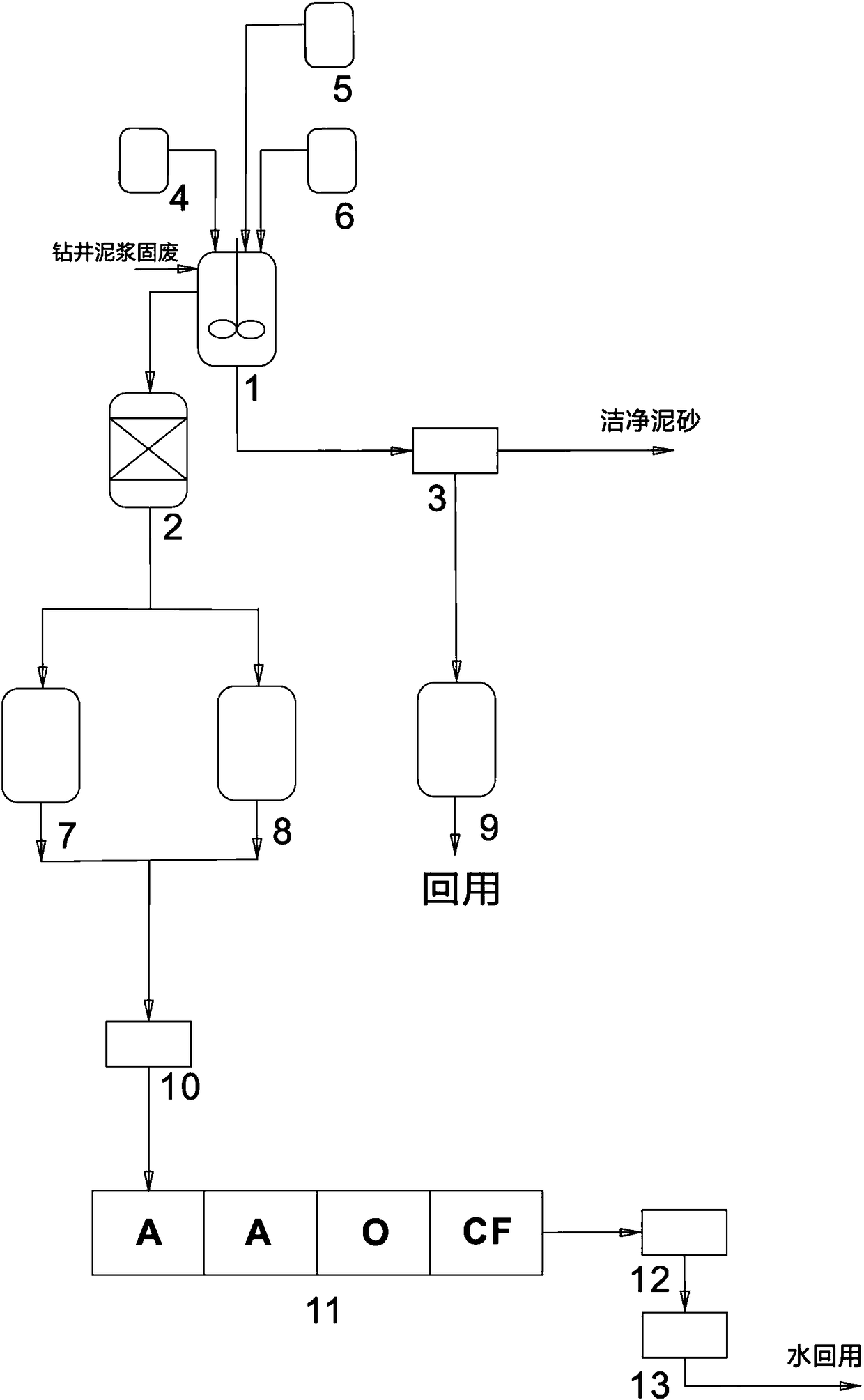

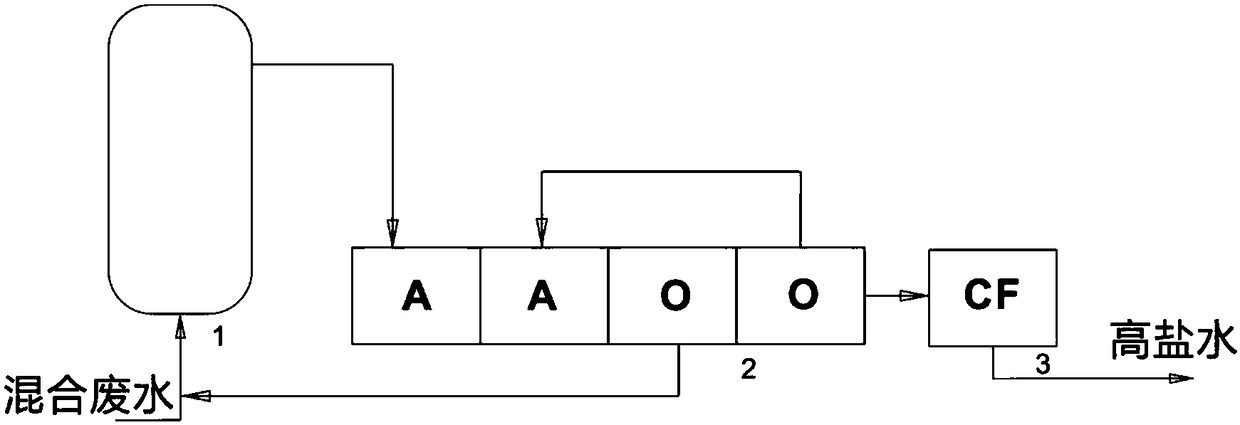

[0068] Example 2 The biological treatment system of the drilling mud solid waste advanced comprehensive treatment system

[0069] Such as figure 2 As shown, the biological treatment section in the deep comprehensive treatment system for drilling mud of the present invention mainly includes four parts: anaerobic, two-stage anoxic, two-stage aerobic and biochar filter.

[0070] After adjusting the pH, pollutant concentration and nutrient ratio in the adjustment tank, the mixed wastewater enters anaerobic treatment (1), inoculates the anaerobic treatment sludge of refinery plant, and controls the temperature and hydraulic retention time. Sulfate is reduced to sulfide, which combines with soluble metal ions to form metal sulfide precipitates.

[0071] After anaerobic treatment, the wastewater enters the anoxic-aerobic treatment section (2). The anoxic-aerobic segment consists of two stages of anoxic (A) and two stages of aerobic (O). The dissolved oxygen of the first-level hyp...

Embodiment 3

[0073] Embodiment 3 is used for the advanced treatment of the drilling mud of natural gas exploitation

[0074] Drilling mud solid waste produced by natural gas extraction while drilling is dehydrated by coagulation sedimentation filter press, with a water content of 60-70%, an oil content of 0.5-1.0% measured by gravimetric method, and a pH of 8.5.

[0075] Raise the temperature to 70-75° C. in a slurryer, and once slurry to a slurry with a solid content of 10-20%. Add 0.5-1.0% pretreatment agent, stir, precipitate, and remove the supernatant.

[0076] Slurry for the second time to a slurry with a solid content of 10-20%, add a deep scavenger at a ratio of 5-10%, stir, settle, and remove the supernatant.

[0077] Slurry the sediment three times to make a slurry with a solid content of 10-20%, stir it well, and send it to a filter press dehydration device for dehydration.

[0078] Pretreatment agent formula: 30% sodium lactate, 20% ammonium persulfate, 5% alkylsulfonate, 3% ...

Embodiment 4

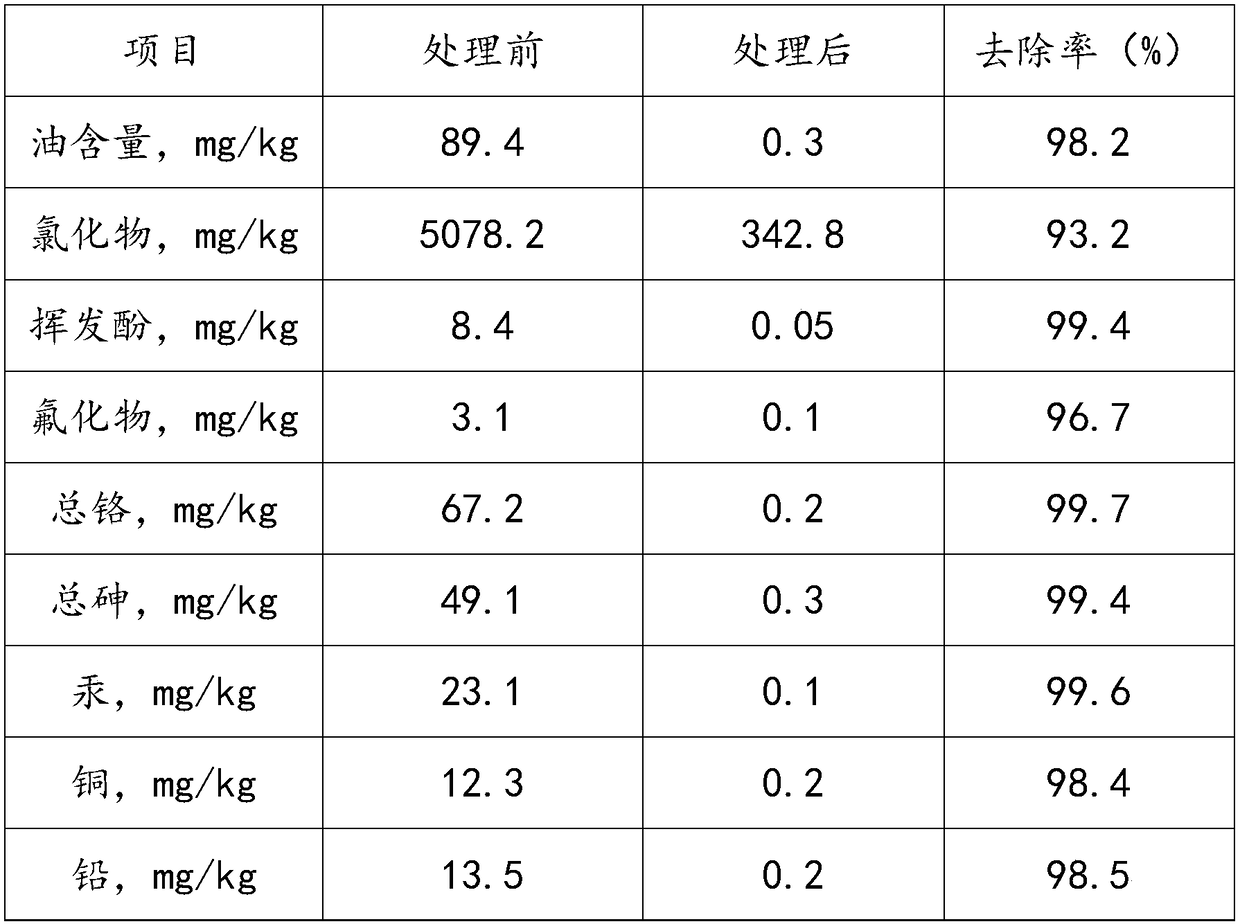

[0092] Embodiment 4 is used for the advanced treatment of the drilling mud of oil extraction

[0093] Drilling mud solid waste produced while drilling in oil production is dehydrated by coagulation sedimentation filter press, with a water content of 60-70%, an oil content of 5.0-10.0% measured by gravimetric method, and a pH of 8.2-8.8.

[0094] A slurry with a solid content of 1-3% is prepared by primary slurrying, and a slurry with a solid content of 2-5% is produced by secondary slurrying, and other steps are the same as in Example 3.

[0095] Table 3 Changes in main technical indicators before and after drilling mud solid waste treatment

[0096]

[0097]

[0098] Table 4 Main technical indicators after treatment of mixed waste liquid generated from drilling mud solid waste treatment

[0099] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com