Efficient bio-organic fertilizer and preparation method thereof

A bio-organic fertilizer, high-efficiency technology, applied in the direction of organic fertilizers, fertilization methods, inorganic fertilizers, etc., can solve the problems of soil fertility decline, degradation of soil biological properties, poor ability to prevent drought and waterlogging, etc., and achieve long-lasting fertilizer supply , Improve crop absorption and growth, increase the effect of species and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

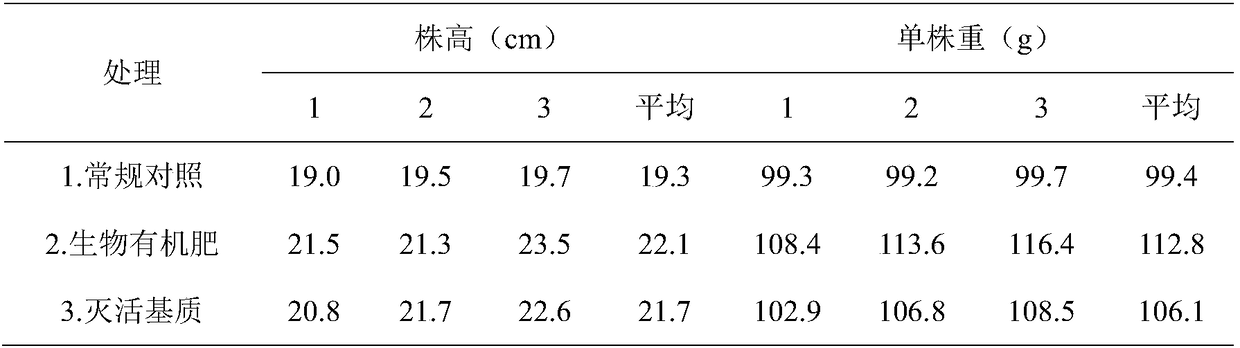

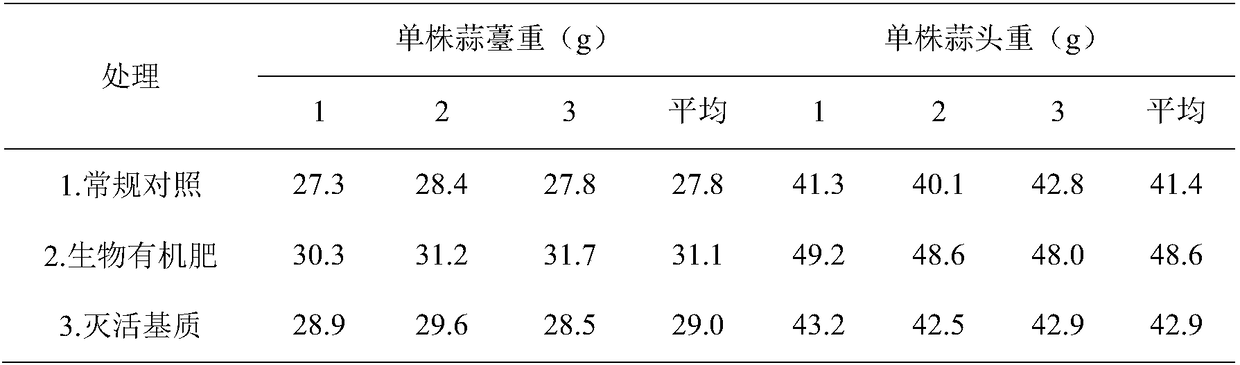

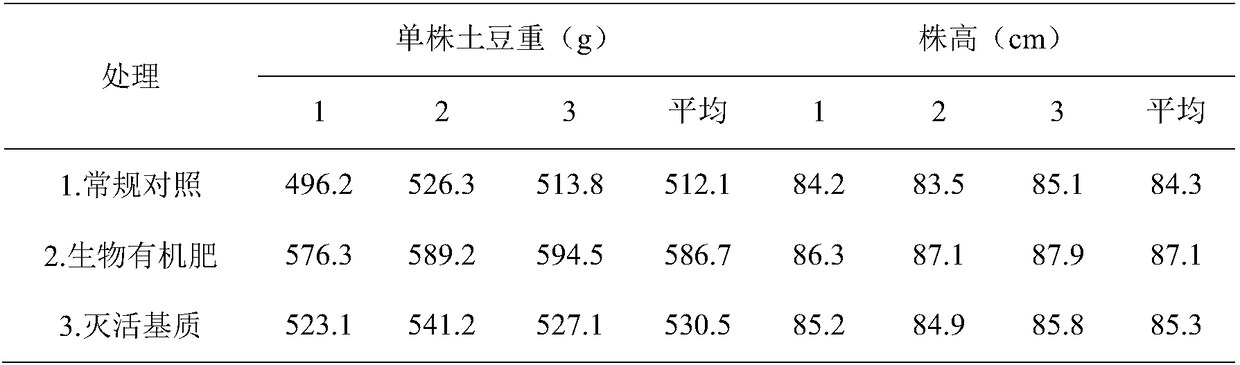

Examples

Embodiment 1

[0034] Basic nutrient fertilizer comprises the component of following mass percent: ammonium sulfate 72% (the content of nitrogen element is 21.2% in ammonium sulfate), potassium nitrate 5% (the content of nitrogen element is 13.8% in potassium nitrate, and the content of potassium element is 38.6%) %), potassium sulfate 5% (the content of potassium element in potassium sulfate is 44.8%), and the proportion of trace elements in silicon, calcium, magnesium, etc. is 18%.

[0035] After the basic nutrient fertilizer is stirred and pulverized, enter the granulation drum and spray the fulvic acid solution (the spraying quality is 3% of the basic nutrient fertilizer quality); after granulation, carry out drying treatment, and the temperature of the primary drying drum is controlled at 550-650°C, the temperature of the secondary drying drum is controlled at 300-500°C, the temperature of the particles after cooling is controlled at 70-80°C; the particles are sieved, and the particle si...

Embodiment 2

[0045] Basic nutrient fertilizer comprises the component of following mass percent: ammonium sulfate 65% (the content of nitrogen element is 21.2% in the ammonium sulfate), monoammonium phosphate 5% (the content of nitrogen element is 12.2% in the monoammonium phosphate, and the content of phosphorus element is 26.9%), potassium nitrate 10% (the content of nitrogen in potassium nitrate is 13.8%, the content of potassium is 38.6%), potassium sulfate 5% (the content of nitrogen in potassium nitrate is 44.8%), silicon, calcium, The proportion of trace elements such as magnesium is 20%.

[0046] After the basic nutrient fertilizer is stirred and pulverized, enter the granulation drum and spray the fulvic acid solution (the spraying quality is 3% of the basic nutrient fertilizer quality); after granulation, carry out drying treatment, and the temperature of the primary drying drum is controlled at 550-650°C, the temperature of the secondary drying drum is controlled at 300-500°C, t...

Embodiment 3

[0056] Basic nutrient fertilizer comprises the component of following mass percent: ammonium sulfate 63% (the content of nitrogen element is 21.2% in ammonium sulfate), monoammonium phosphate 5% (in the monoammonium phosphate, nitrogen element content is 12.2%, and the content of phosphorus element is 26.9%), potassium nitrate 10% (the content of nitrogen element in potassium nitrate is 13.8%, the content of potassium element is 38.6%), potassium sulfate 5% (the content of nitrogen element in potassium sulfate is 44.8%), silicon, calcium, The proportion of trace elements such as magnesium is 22%.

[0057] After the basic nutrient fertilizer is stirred and pulverized, enter the granulation drum and spray the fulvic acid solution (the spraying quality is 3.5% of the basic nutrient fertilizer quality); after granulation, carry out drying treatment, and the temperature of the primary drying drum is controlled at 550-650°C, the temperature of the secondary drying drum is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com