Antibacterial environment-friendly cushion packaging material preparation method

A buffer packaging and environmental protection technology, applied in the production of bulk chemicals, etc., can solve the problems of white pollution, high cost, etc., and achieve the effects of good antibacterial, good inhibition effect, good mechanical properties and buffer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

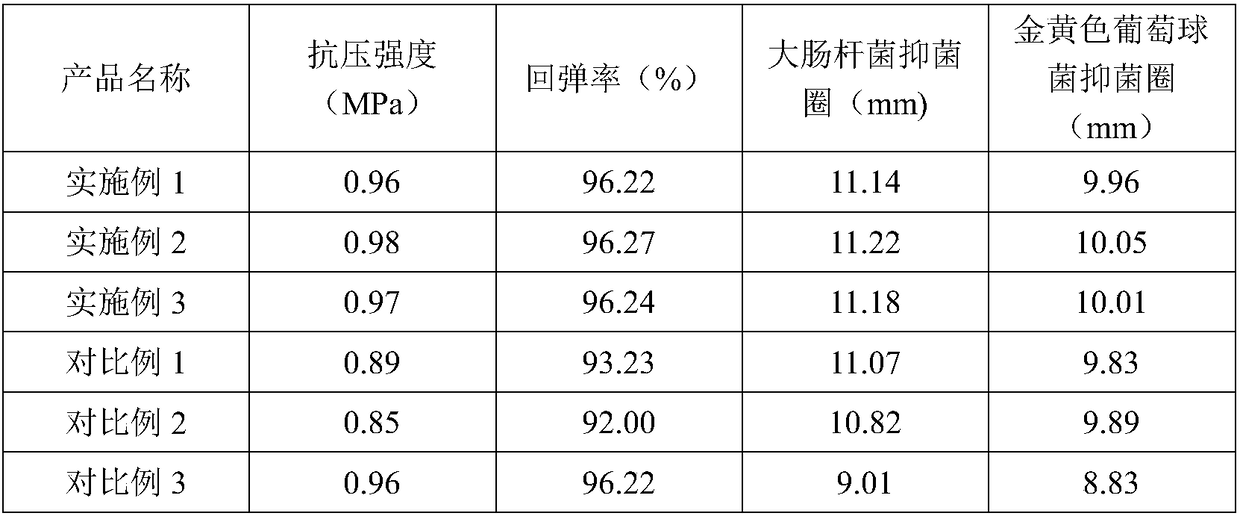

Examples

Embodiment 1

[0027] A preparation method of an antibacterial and environment-friendly cushioning packaging material, the ingredients are calculated by weight, comprising the following steps:

[0028] (1) Get 20 parts of cotton stalk scraps and pulverize them, and cross a 60-mesh sieve;

[0029] (2) Add 30 parts of 2mol / L sodium hydroxide solution and stir for 20 minutes;

[0030] (3) filtering and cleaning to obtain product A;

[0031] (4) Take 10 parts of furfural slag and sieve to remove impurities, immerse in dilute sodium hydroxide solution and stir mechanically for 1 hour, filter and wash with distilled water until neutral, move to an oven to dry at 60°C, and crush to 40 mesh screen;

[0032] (5) Add 10 parts of sunflower seed hull powder and 200 parts of benzene-ethanol solution and mix, extract at 90°C for 5 hours, and discard the extract, wherein the volume ratio of benzene and ethanol is 2:1;

[0033] (6) Add 200 parts of ethanol aqueous solution, adjust the pH to 4 with glacia...

Embodiment 2

[0041] A preparation method of an antibacterial and environment-friendly cushioning packaging material, the ingredients are calculated by weight, comprising the following steps:

[0042] (1) Get 25 parts of cotton stalk scraps and pulverize, cross 80 mesh sieves;

[0043] (2) Add 40 parts of 2mol / L sodium hydroxide solution and stir for 25 minutes;

[0044] (3) filtering and cleaning to obtain product A;

[0045] (4) Take 15 parts of furfural slag and sieve to remove impurities, immerse in dilute sodium hydroxide solution and stir mechanically for 1 hour, filter and wash with distilled water until neutral, move to an oven to dry at 60°C, and crush to 40 mesh screen;

[0046] (5) Add 15 parts of sunflower seed hull powder and 200 parts of benzene-ethanol solution and mix, extract at 90°C for 5.5 hours, and discard the extract, wherein the volume ratio of benzene and ethanol is 2:1;

[0047] (6) Add 200 parts of aqueous ethanol, adjust the pH to 4.5 with glacial acetic acid, ...

Embodiment 3

[0056] A preparation method of an antibacterial and environment-friendly cushioning packaging material, the ingredients are calculated by weight, comprising the following steps:

[0057] (1) Get 30 parts of cotton stalk scraps and pulverize, cross 80 mesh sieves;

[0058] (2) Add 50 parts of 2mol / L sodium hydroxide solution and stir for 30 minutes;

[0059] (3) filtering and cleaning to obtain product A;

[0060](4) Take 20 parts of furfural slag and sieve to remove impurities, immerse in dilute sodium hydroxide solution and stir mechanically for 1 hour, filter and wash with distilled water until neutral, move to an oven to dry at 60°C, and crush to 40 mesh screen;

[0061] (5) Add 20 parts of sunflower seed hull powder and 200 parts of benzene-ethanol solution and mix, extract at 90°C for 6 hours, and discard the extract, wherein the volume ratio of benzene and ethanol is 2:1;

[0062] (6) Add 200 parts of ethanol aqueous solution, adjust the pH to 5 with glacial acetic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com