Powder coating, and preparation method and application thereof

A technology of powder coatings and raw materials, applied in the field of coatings, to achieve excellent waterproof, excellent leveling performance, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

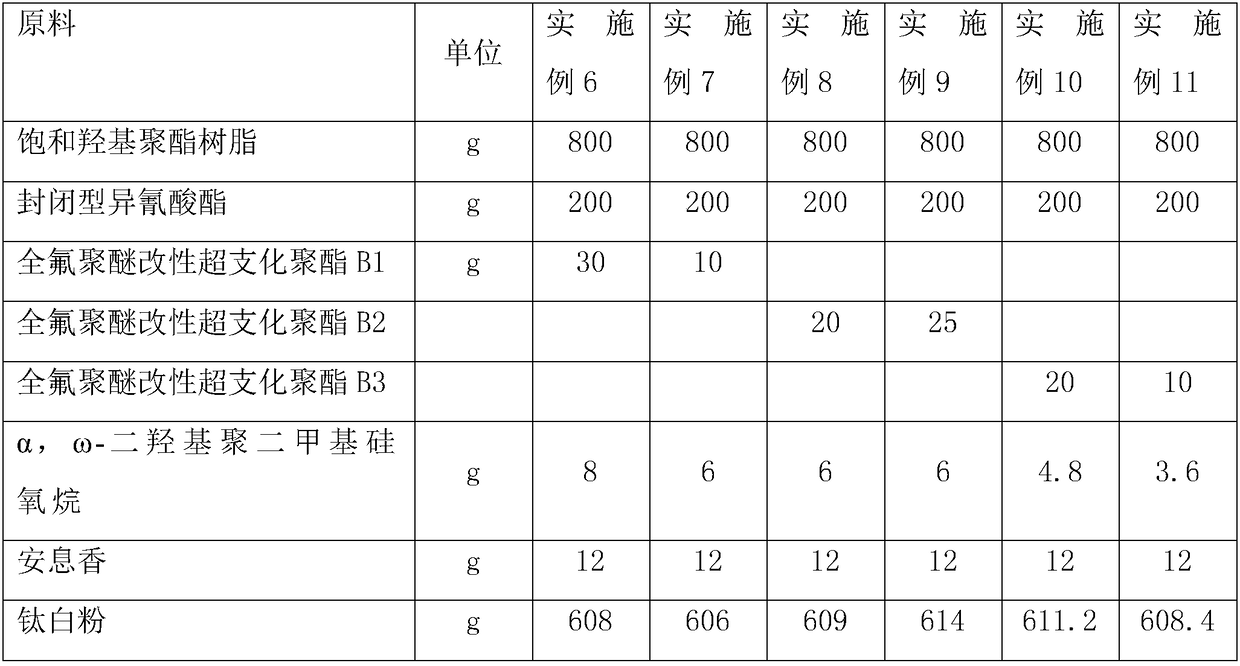

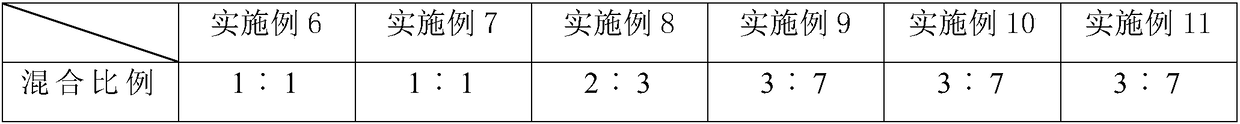

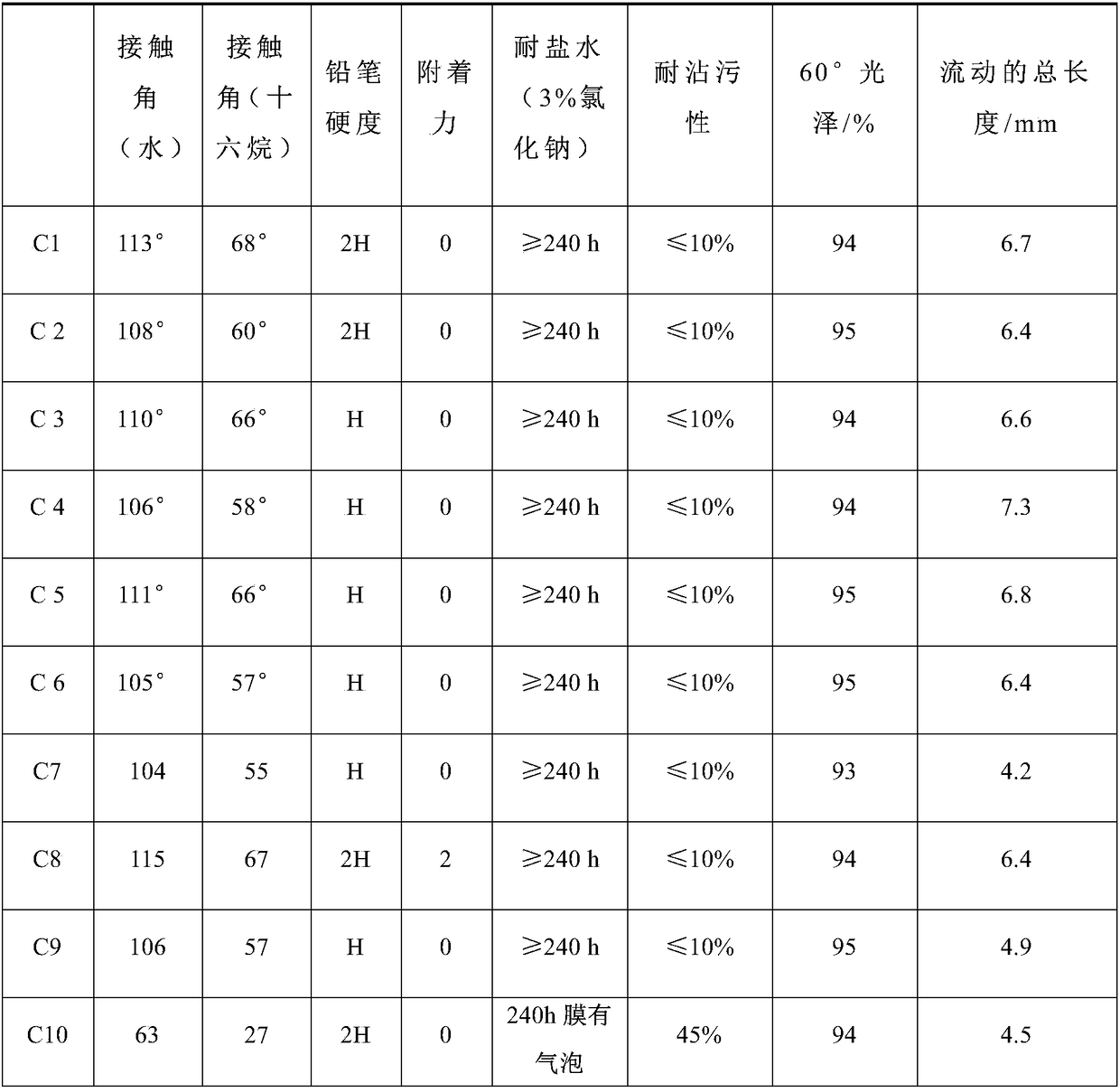

Examples

Embodiment 1

[0033] The preparation of embodiment 1 hyperbranched polyester

[0034]In a four-neck flask equipped with a thermometer, water separator, stirrer, reflux condenser, and nitrogen protection, add 10g of trimethylolpropane, 490g of 2,2-bis(hydroxymethyl)propionic acid, and add 2.5g P-toluenesulfonic acid, xylene 400g, stir and heat up to reflux state, after reacting for 6-12 hours, until water no longer distills out in the water separator, xylene is removed by vacuum distillation, and the product is dissolved in a certain amount of In acetone, after adding n-hexane, stirring and standing still, the obtained precipitated product is the hyperbranched polyester A1, and the measured hydroxyl value of A1 is 390-400 mgKOH / g.

Embodiment 2

[0035] The preparation of embodiment 2 hyperbranched polyester

[0036] In a four-necked flask equipped with a thermometer, water separator, stirrer, reflux condenser, and nitrogen protection, add 100g of trimethylolpropane, 400g of 2,2-bis(hydroxymethyl)propionic acid, and add 2.5g P-toluenesulfonic acid, xylene 400g, stir and heat up to reflux state, after reacting for 6-12 hours, until there is no more water distilling out in the water separator, xylene is removed by vacuum distillation, and the product is dissolved in a certain amount of In acetone, after adding n-hexane, stirring and standing still, the obtained precipitated product is the hyperbranched polyester A2, and the measured hydroxyl value of A2 is 360-370 mgKOH / g.

Embodiment 3

[0037] Example 3 Preparation of perfluoropolyether modified hyperbranched polyester

[0038] In a four-necked flask equipped with a thermometer, a stirrer, a reflux condenser, and a constant pressure dropping funnel, add 150 g of the prepared hyperbranched polyester A1, 300 g of acetone, and 2 g of triethylamine, stir and dissolve, and place in an ice bath In the process, 67g of perfluoropolyetheryl fluoride with a number average molecular weight of 5000 was dissolved in 300g of m-trifluorotoluene, transferred to a constant pressure dropping funnel, and added dropwise while stirring. After the addition is complete, raise the temperature to 25°C and continue the reaction for 3-6 hours. Use IR to detect whether the carbonyl group of the acid fluoride disappears to monitor whether the reaction is complete. After the reaction is completed, the solvent is distilled off under reduced pressure, and the product B1 is obtained after drying, which is the perfluoropolyether modified hype...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com