Composite air compressor oil composition and preparation method thereof

A technology of air compressor and composition, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem of difficult separation of oil and water, and achieve the effect of reducing friction coefficient, reducing wear and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

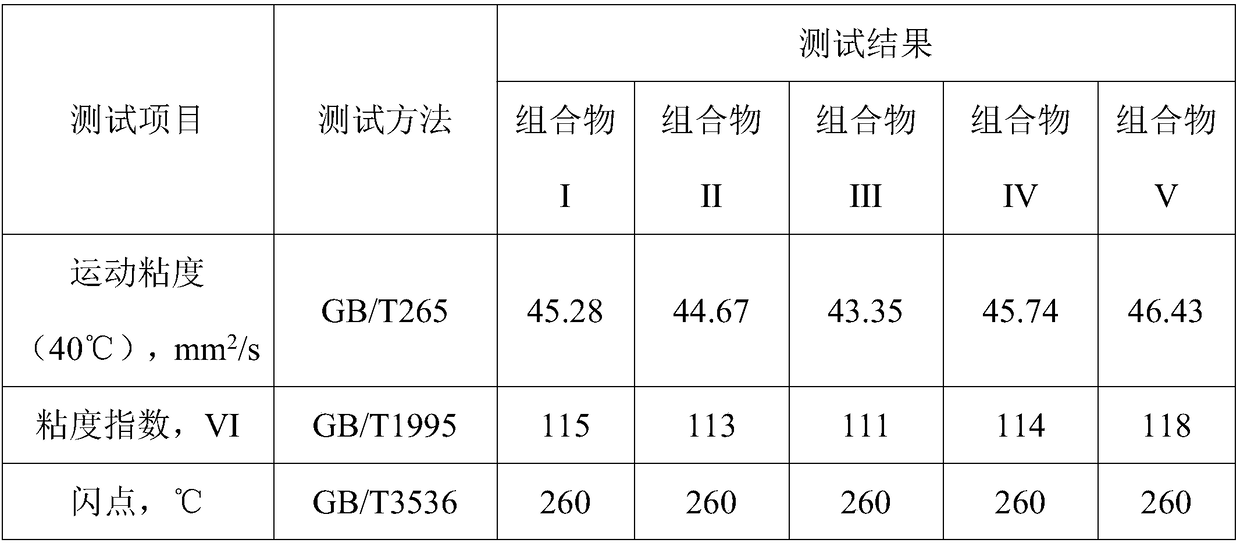

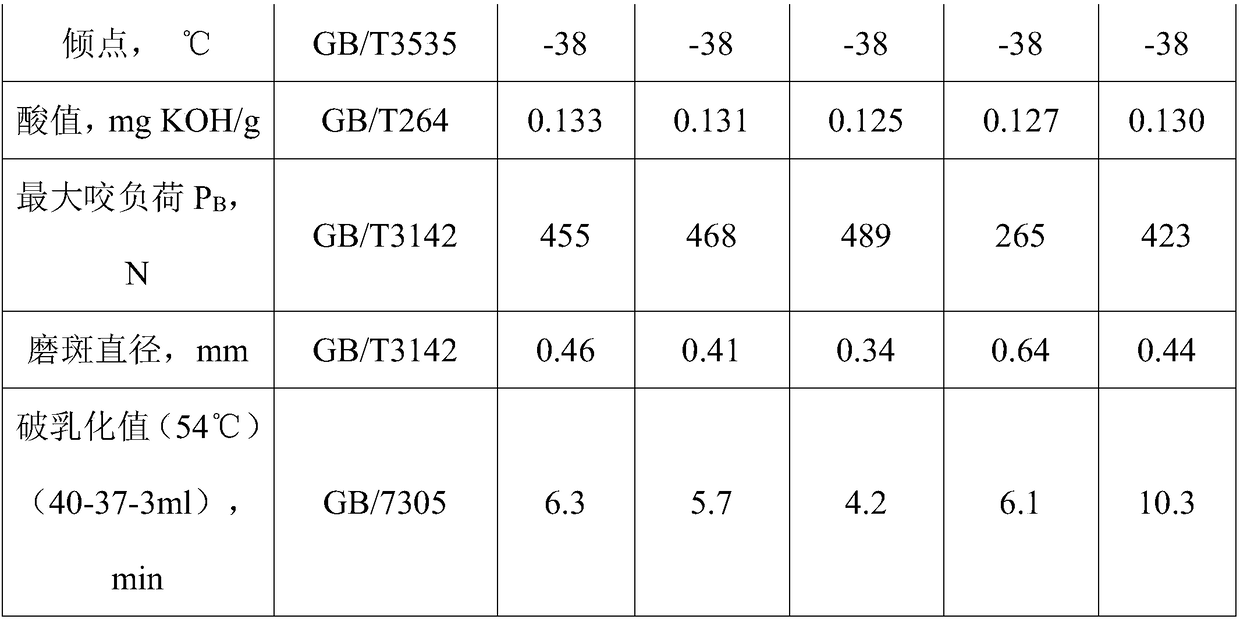

Examples

Embodiment 1

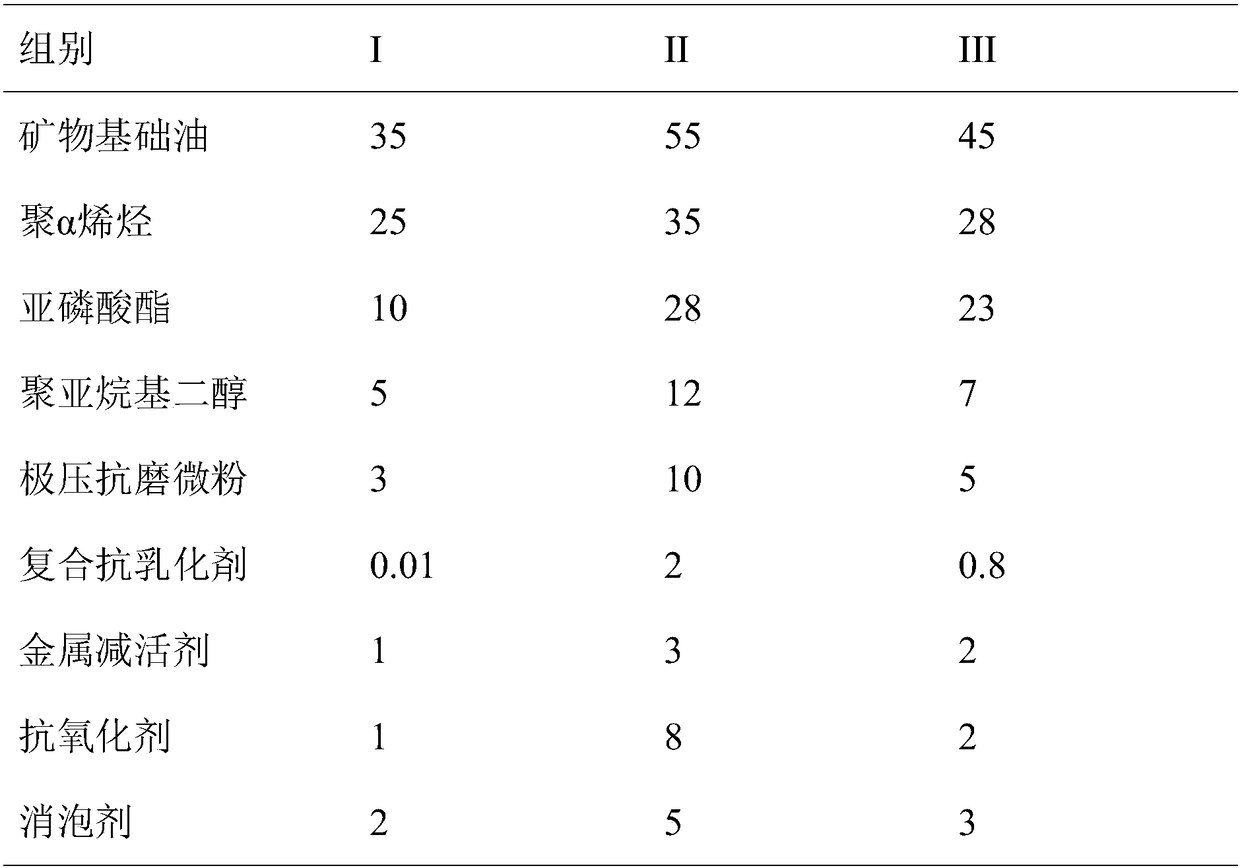

[0022] Embodiment 1: the preparation ratio of each raw material in the composite air compressor engine oil composition

[0023] The various raw materials in the composite air compressor oil composition were mixed according to the mass parts described in Table 1, and three groups of composite air compressor oil compositions I to III with different mixing ratios were obtained.

[0024] The composite air compressor engine oil composition of different mixing ratios (mass parts) of table 1

[0025]

Embodiment 2

[0026] Embodiment 2: the preparation method of composite air compressor engine oil composition

[0027] Step 1. Preparation of extreme pressure anti-wear micropowder: Prepare ferric sulfate and distilled water to form a ferric sulfate solution with a molar concentration of 0.01mol / L, adjust the pH value to 2, and then add phenylethyl naphthol polyoxyethylene to the ferric sulfate solution Ultrasonic emulsification after ether, the ultrasonic power is 100W, and the emulsification precursor is prepared; then an electric field is applied to the emulsification precursor, and the current density is 0.5A / dm 2 , depositing loose powder on the surface of the cathode; finally cleaning, suction filtering and drying the powder to obtain the extreme pressure anti-wear micropowder;

[0028] Preparation of composite anti-emulsifier: under the protection of nitrogen, put laurylamine dipropylenediamine and ethylene oxide with a molar ratio of 1:15 into the reaction kettle, and then add the ca...

Embodiment 3

[0031] Embodiment 3: the preparation method of composite air compressor machine oil composition

[0032] Step 1. Preparation of extreme pressure anti-wear micropowder: Zinc sulfate and distilled water are prepared into a zinc sulfate solution with a molar concentration of 1.5 mol / L, and the pH value is adjusted to 6, and then phenylethylnaphthol polyoxyethylene is added to the zinc sulfate solution Ultrasonic emulsification after ether, the ultrasonic power is 500W, and the emulsification precursor is prepared; then an electric field is applied to the emulsification precursor, and the current density is 6.5A / dm 2 , depositing loose powder on the surface of the cathode; finally cleaning, suction filtering and drying the powder to obtain the extreme pressure anti-wear micropowder;

[0033] Preparation of composite anti-emulsifier: under the protection of nitrogen, put laurylamine dipropylenediamine and ethylene oxide with a molar ratio of 1:75 into the reaction kettle, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com