Preparation method for nickel phosphide-nitrogen doped graphite oxide foil composite nano material

A composite nanomaterial, graphite foil technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as poor electrocatalytic hydrogen evolution catalytic effect, poor catalytic process stability, and complex experimental process. , to achieve the effects of good product stability, good product uniformity, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

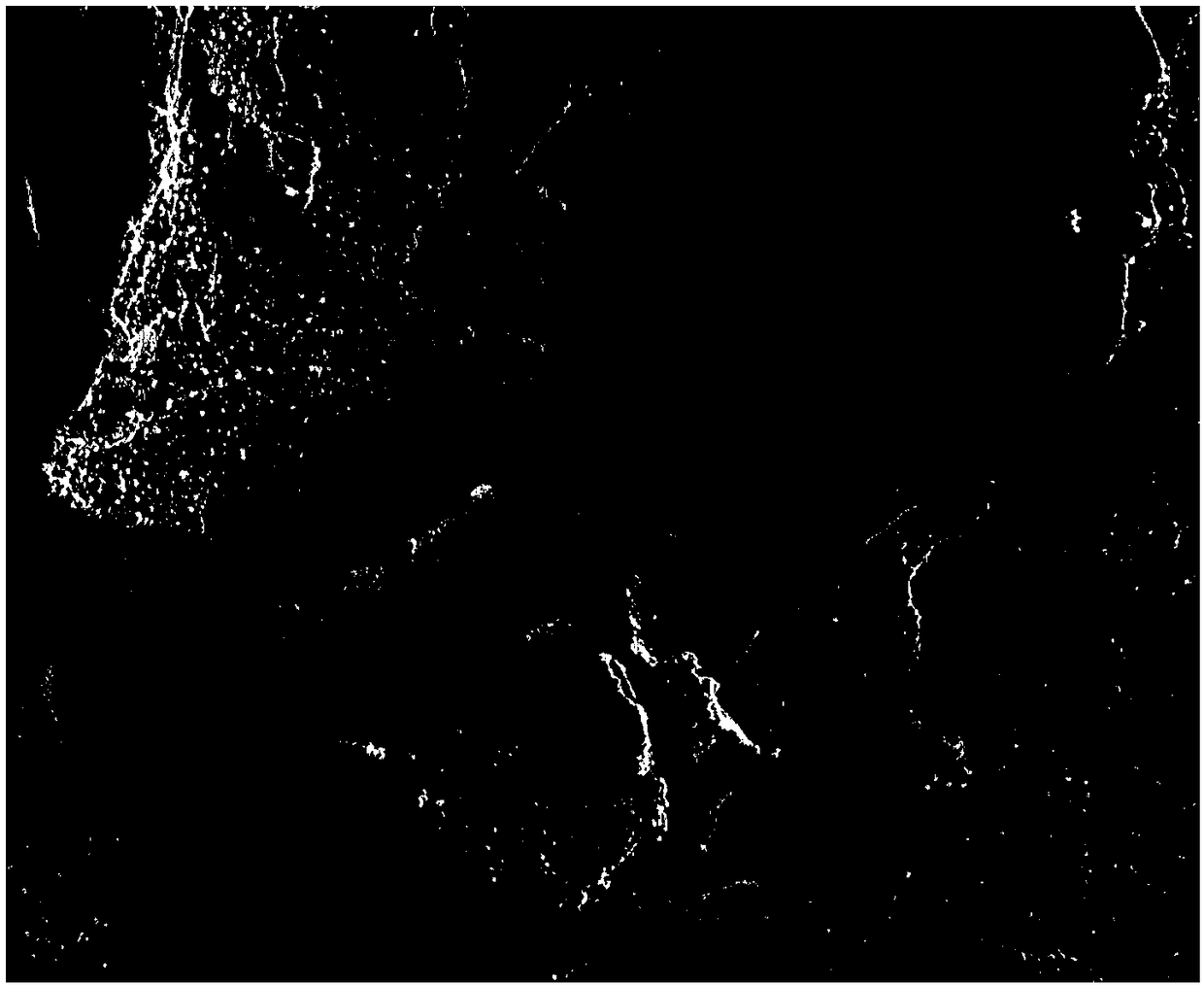

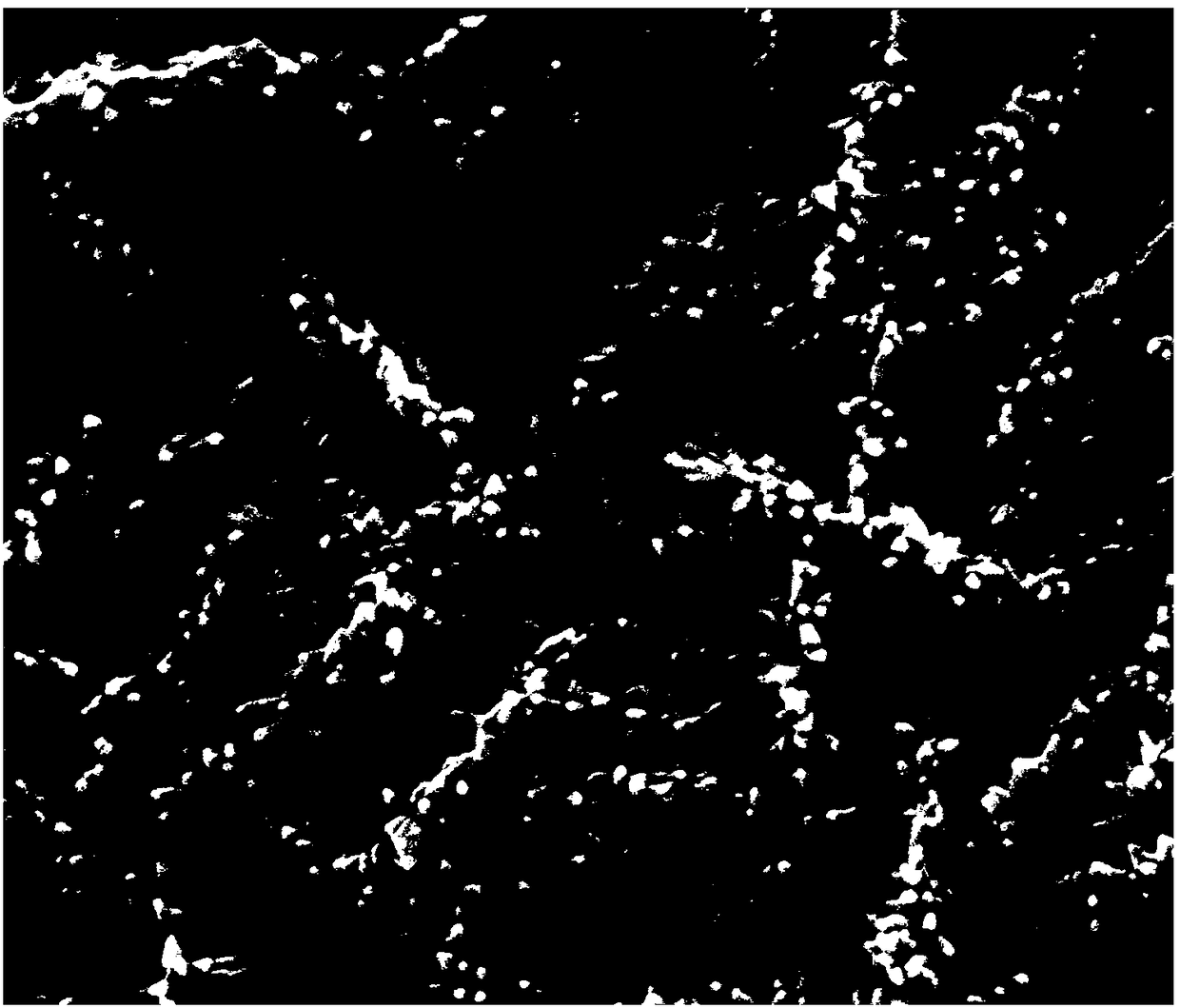

[0035] Use a ruler to cut 4 pieces of 3cm*5cm (weighing about 0.6g) GF into 25ml 65% HNO 3 And 25mL98%H 2 SO 4 Soaked in the mixed solution for 36h, and heated to 80 ℃ with microwave, microwave power is 300W, after the reaction, the soaked graphite oxide foil is taken out, washed with deionized water and absolute ethanol for several times, and then placed in a freeze drying oven for drying , The freeze drying temperature is -50°C, the vacuum degree is 30 Pa, and the drying time is 30 hours.

[0036] Weigh ammonium fluoride (0.222g), thiourea (0.54g), nickel nitrate (0.29g), water (40mL) and dissolve in 40ml deionized water. After stirring for 30min, a uniform and transparent solution is obtained. Pour the mixed solution Add 0.2g graphite oxide foil to a 50ml reaction kettle, fix the graphite oxide foil in the middle of the reaction kettle with a glass slide in an inclined manner, pass nitrogen to remove oxygen in the reaction solution, and pass nitrogen during the reaction Prote...

Embodiment 2

[0044] Use a ruler to cut 4 pieces of 3cm*5cm (weighing about 0.6g) GF into 25ml 65% HNO 3 And 25mL98% H 2 SO 4 Soak in the mixed solution for 12h, and use microwave to heat to 80℃, microwave power is 300W, after the reaction, take out the soaked graphite oxide foil, wash it with deionized water and absolute ethanol for several times, and put it into a freeze drying oven for drying The freeze-drying temperature is -52°C, the vacuum degree is 50 Pa, and the drying time is 36 hours.

[0045] Weigh ammonium fluoride (0.222g), thiourea (0.54g), nickel nitrate (0.29g), water (40mL) and dissolve in 40ml deionized water. After stirring for 30min, a uniform and transparent solution is obtained. Pour the mixed solution Add 0.2g graphite oxide foil to a 50ml reaction kettle, fix the graphite oxide foil in the middle of the reaction kettle with a glass slide in an inclined manner, pass nitrogen to remove oxygen in the reaction solution, and pass nitrogen during the reaction Protected, nitr...

Embodiment 3

[0049] Use a ruler to cut 4 pieces of 3cm*5cm (weighing about 0.6g) GF into 25ml 65% HNO 3 And 25mL98%H 2 SO 4 Soak in the mixed solution for 48h, and use microwave to heat to 80℃, microwave power is 300W, after the reaction, take out the soaked graphite oxide foil, wash it with deionized water and absolute ethanol for several times, and put it into a freeze drying oven for drying , The freeze-drying temperature is -48°C, the vacuum degree is 10 Pa, and the drying time is 36 hours.

[0050] Weigh ammonium fluoride (0.222g), thiourea (0.54g), nickel nitrate (0.29g), water (40mL) and dissolve in 40ml deionized water. After stirring for 30min, a uniform and transparent solution is obtained. Pour the mixed solution Add 0.2g graphite oxide foil to a 50ml reaction kettle, fix the graphite oxide foil in the middle of the reaction kettle with a glass slide in an inclined manner, pass nitrogen to remove oxygen in the reaction solution, and pass nitrogen during the reaction Protected, nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com